Template, resin machine, and method for heating nozzle of template

A nozzle and template technology, applied in the field of nozzle heating, can solve problems such as temperature unevenness, resin particle shape deviation, etc., and achieve the effect of suppressing temperature unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

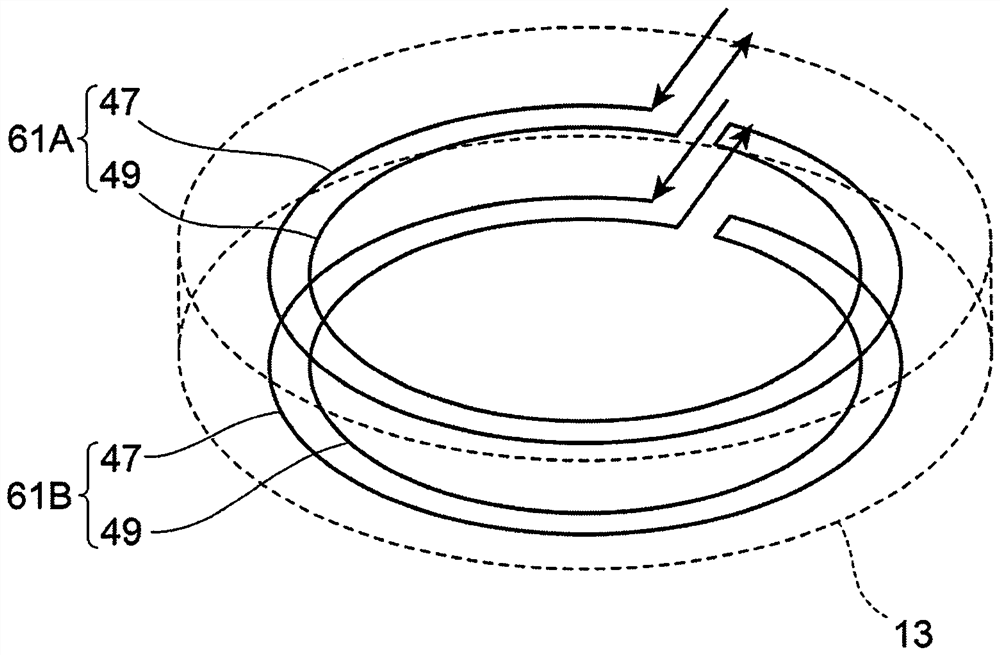

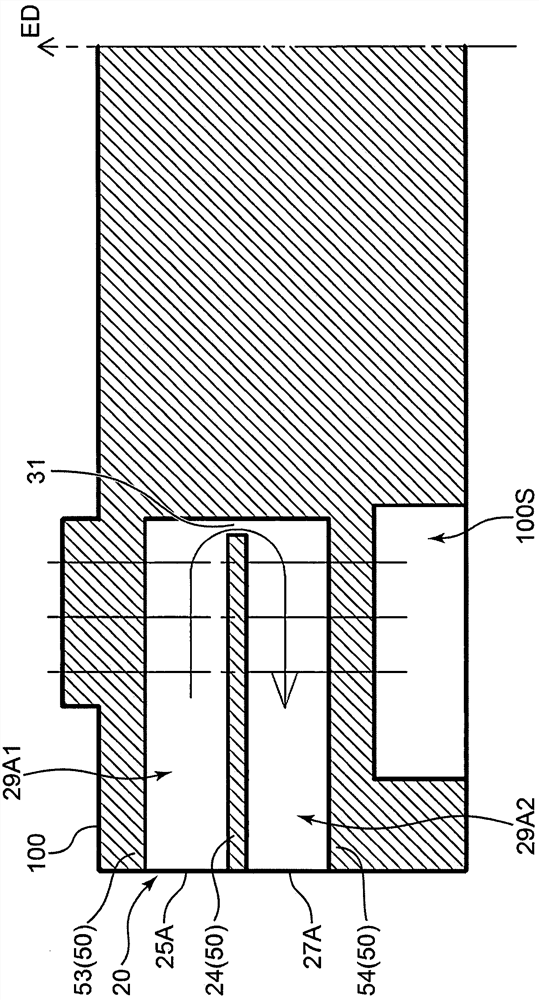

[0060] Hereinafter, each embodiment of the present invention and modifications thereof will be described in detail with reference to the drawings. The die plate according to each embodiment of the present invention is used in a granulation device for resin pellets, and has a large number of nozzles through which molten resin is extruded, and at least one heating medium for flowing a heating medium that heats the nozzle walls forming the nozzles. flow path. In addition, a cutter device (not shown) is arranged on the nozzle surface on the resin injection side of the template, and the resin extruded from the nozzle is cut with the cutter to form resin pellets. This resin cleavage is performed in water.

[0061] In addition, the heating medium heated by a heating device not shown is sent to the heating medium flow path. Fluid such as thermal oil or steam is used as the heating medium, and the heating medium flows through the heating medium flow channel and is discharged from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com