Lithium ion battery non-aqueous electrolyte and lithium ion battery

A non-aqueous electrolyte and lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as insufficient high-temperature storage performance and high-temperature cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

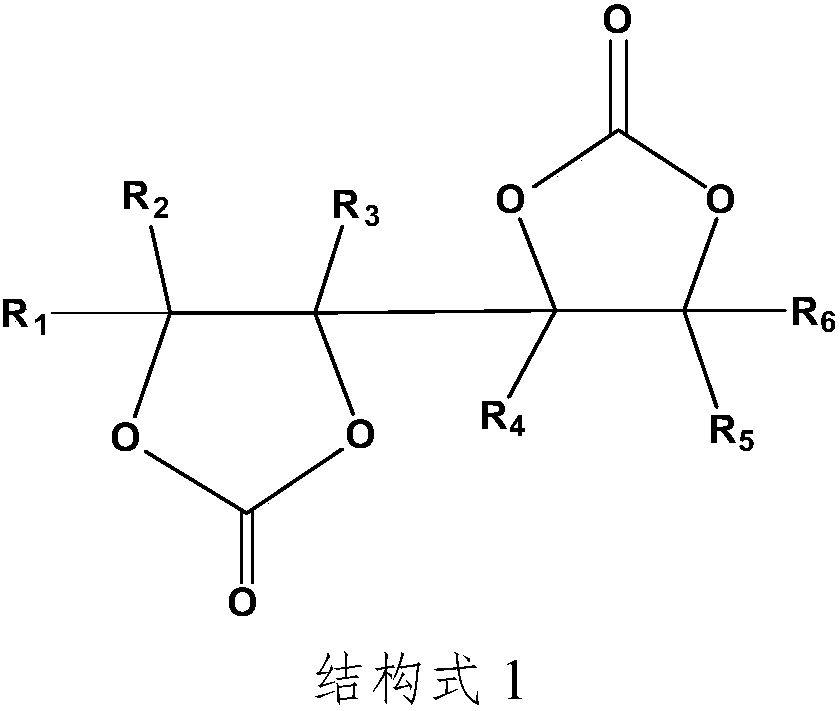

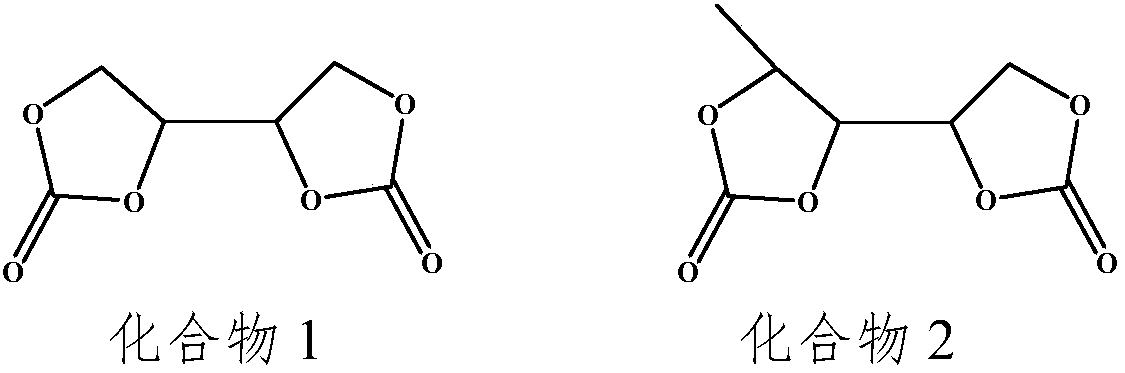

Method used

Image

Examples

preparation example Construction

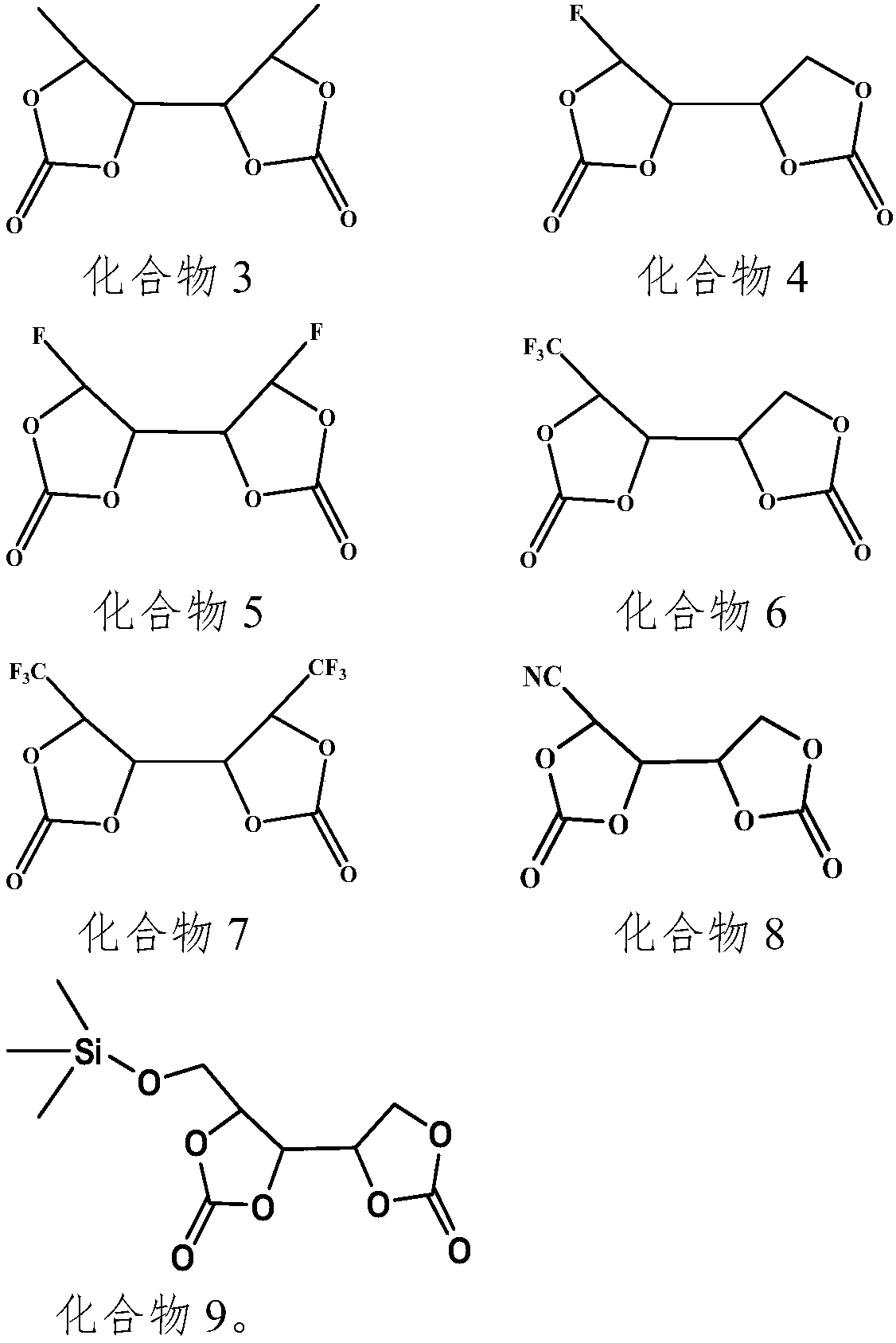

[0037] The preparation of fluorine-containing compound in compound A adopts corresponding carbonate and F 2 / N 2 After fluorination of the mixed gas, it can be purified by recrystallization or column chromatography. An example of its synthetic route is as follows:

[0038]

[0039] The cyano-containing compound in compound A is prepared by chlorinating the corresponding carbonate with sulfuryl chloride, then reacting with NaCN or KCN, and obtaining it through recrystallization or column chromatography purification. An example of its synthetic route is as follows:

[0040]

[0041]The trimethylsiloxy-containing compound in compound A is prepared by the substitution reaction between the corresponding hydroxycarbonate and nitrogen silane, and then purified by recrystallization or column chromatography. An example of its synthetic route is as follows:

[0042]

[0043] In the present invention, compound A and oxalate phosphate are both used as electrolyte additives, a...

Embodiment 1

[0061] This embodiment is used to illustrate the lithium-ion battery non-aqueous electrolyte, lithium-ion battery and preparation method thereof disclosed in the present invention, comprising the following steps:

[0062] The positive electrode preparation steps are: mix the positive electrode active material lithium nickel cobalt manganese oxide LiNi according to the mass ratio of 92:4:3 0.5 co 0.2 mn 0.3 o 2 , conductive carbon black Super-P and binder polyvinylidene fluoride (PVDF), dispersed in N-methyl-2-pyrrolidone (NMP) to obtain positive electrode slurry, which is evenly coated on the aluminum foil Both sides are dried, calendered and vacuum-dried, and aluminum lead-out wires are welded with an ultrasonic welder to obtain a positive plate, the thickness of which is between 120-150 μm.

[0063] Negative electrode preparation steps are: mix artificial graphite, conductive carbon black Super-P, binder styrene-butadiene rubber (SBR) and carboxymethyl cellulose (CMC) acc...

Embodiment 2~12

[0069] Embodiments 2 to 12 are used to illustrate the lithium ion battery non-aqueous electrolyte, lithium ion battery and preparation method thereof disclosed in the present invention, including most of the operating steps in Example 1, the difference being:

[0070] In the non-aqueous electrolyte preparation step:

[0071] Based on the total weight of the non-aqueous electrolytic solution as 100%, the non-aqueous electrolytic solution contains the components in the mass percentages shown in Example 2 to Example 12 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com