Lightweight high-elasticity liquid metal watch shell and production method thereof

A liquid metal and watch technology, applied in the field of watches, can solve the problems of long processing time, consumer loss, accidental drop, etc., and achieve the effect of eliminating cumbersome processing procedures, reducing the difficulty of grinding, and fast mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

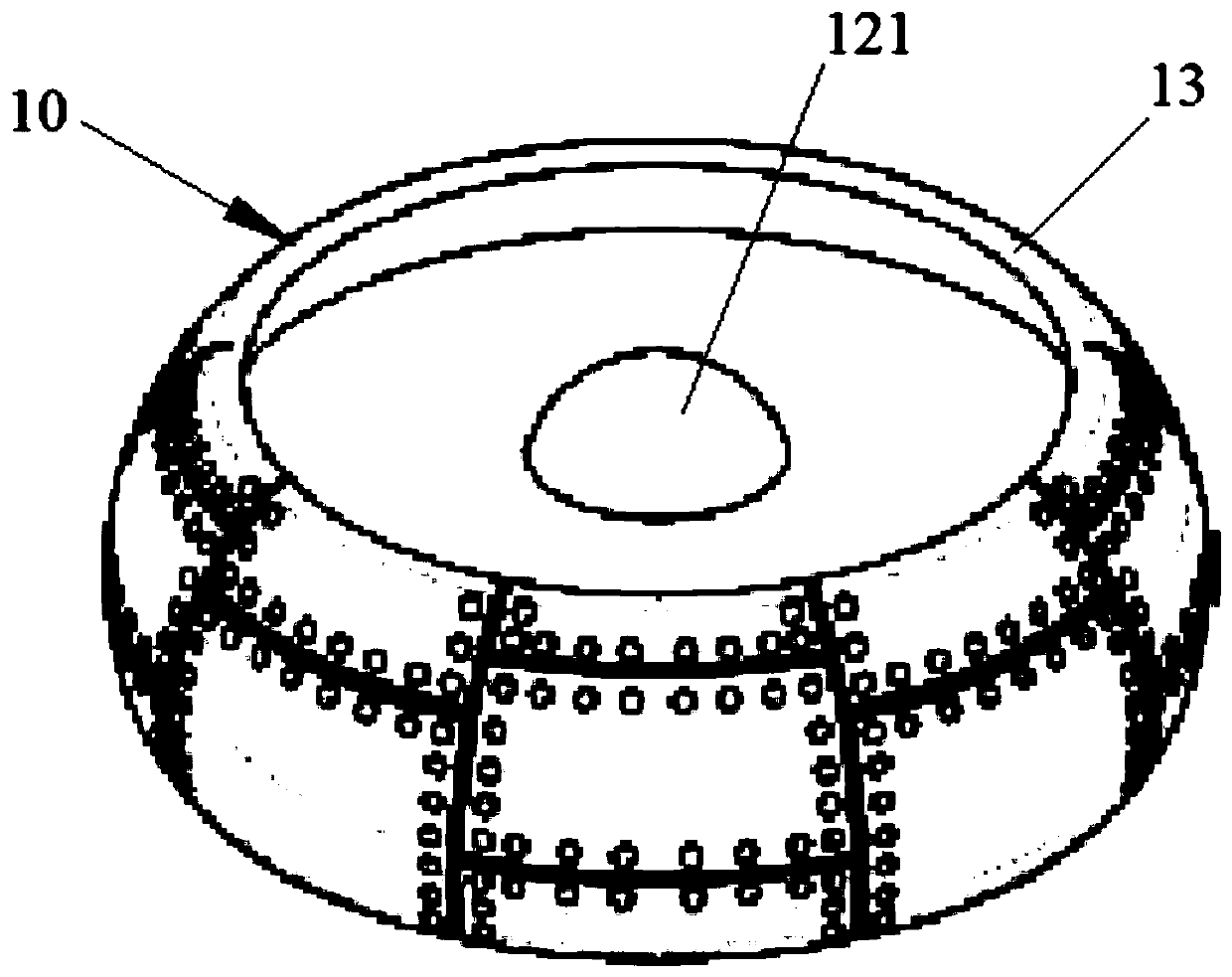

[0061] Please refer to Figure 1 to Figure 4 As shown, it shows the specific structure of the preferred embodiment of the present invention, which is a light-weight high-elastic liquid metal watch case, including the use of liquid metal emulsion to form the watch case main body 10 by injection molding and integrally connected to the The bracelet connector 20 at the bottom of the watch case body 10 .

[0062] The use of liquid metal technology to produce semi-finished watch cases has the following advantages: first, using the characteristics of liquid metal's low melting point, through melting and reshaping, and then through the solidification process, its casting process is more similar to plastic than metal , can be molded at one time, eliminating the cumbersome procedures of processing. Second, liquid metal has extremely superior performance. It is light but extremely strong, and has high elasticity. Its strength is three times that of stainless steel. It can play a greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com