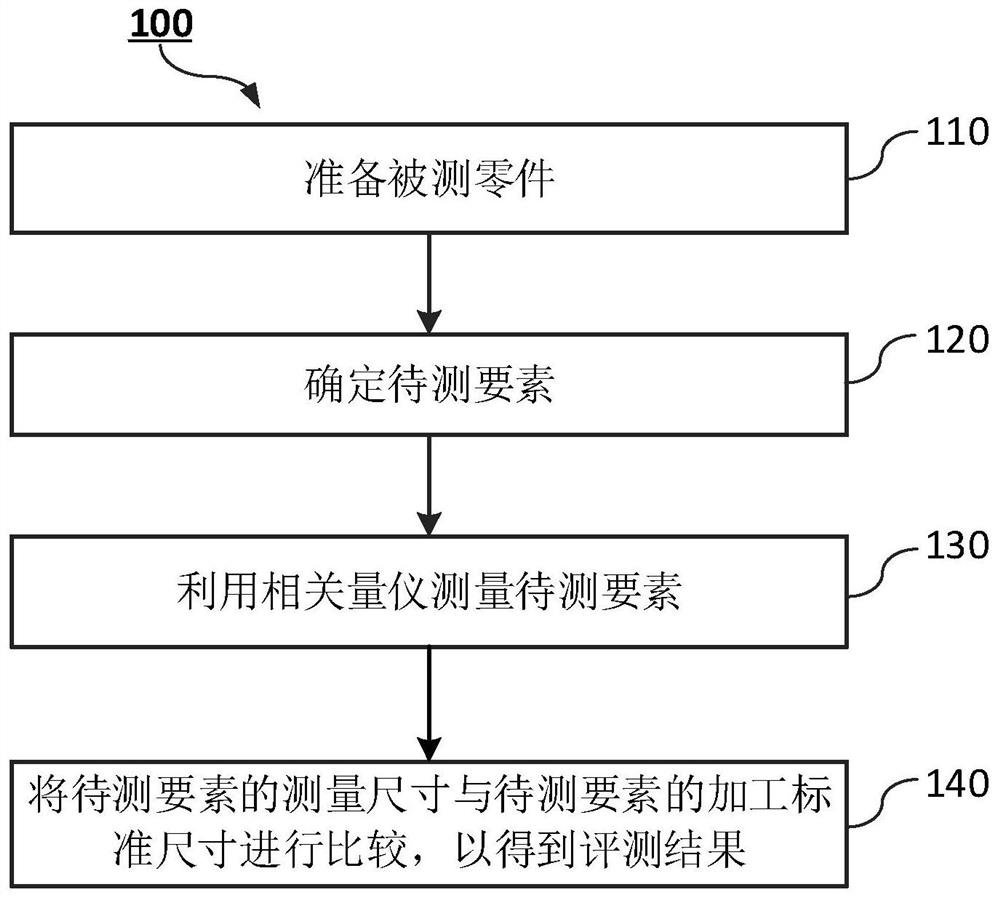

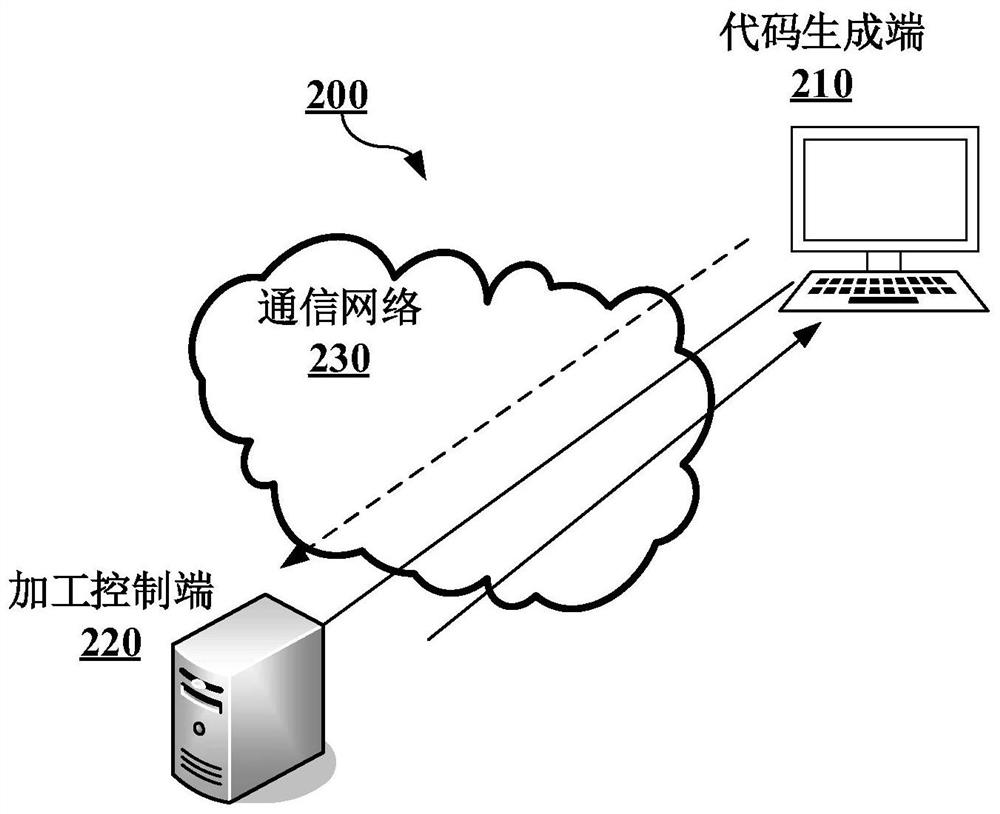

Evaluation Method of Part Machining Dimensions

A technology of part processing and evaluation method, applied in the field of part processing size evaluation method and corresponding device for realizing the method, can solve the problems of expensive testing equipment, cumbersome process and high cost, so as to reduce testing cost, eliminate cumbersome procedures, reduce The effect of using the meter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

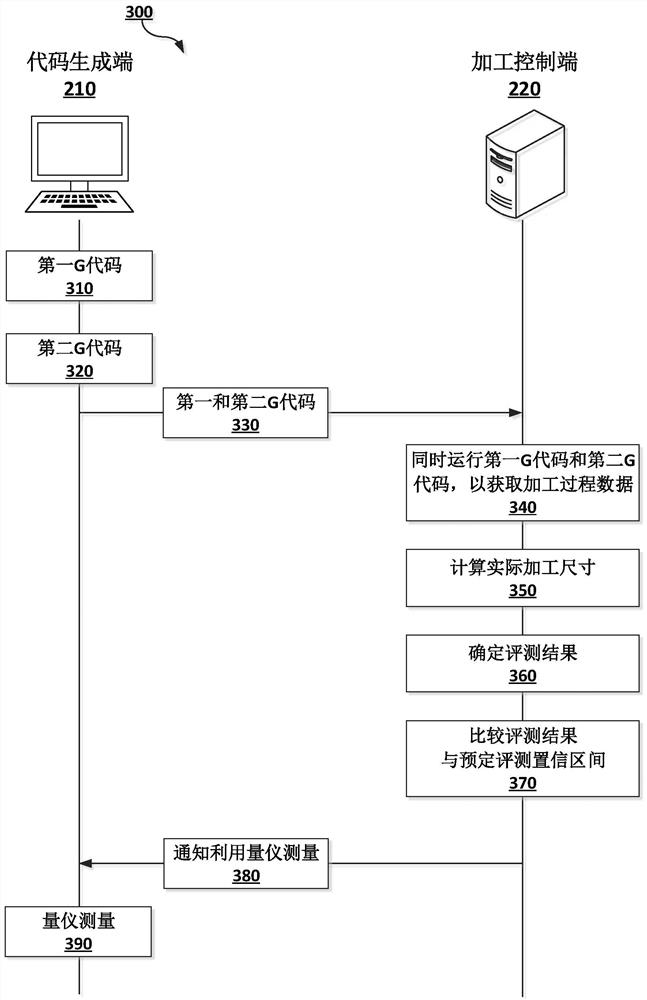

[0070] N: "10", MTYPE: "Pstart", MARK: "10", DE: "-0.01", UE: "0.01", SPD: "1", NUM: "3", KFACT: "cur".

example 2

[0072] N: "50", MTYPE: "Pend", MARK: "10", DE: "-0.01", UE: "0.01", SPD: "1", NUM: "3", KFACT: "cur".

[0073] In the above example 1, N: "10" means starting from the 10th line of the first G code, MTYPE: "Pstart" means the starting point of length size evaluation, MARK: "10" means the element to be evaluated is 10mm in length size, DE : "-0.01" indicates that the lower deviation is -0.01, UE: "0.01" indicates that the upper deviation is 0.01, SPD: "1" indicates that the evaluation data sampling mode is mode 1 in Table 1 (that is, continuous fixed-point sampling), NUM : "3" indicates that the total number of sampling points is 3.

[0074] The above example 2 is the same as example 1, indicating the length dimension evaluation, MTYPE: "Pend" indicates the end point of the corresponding length dimension evaluation, and the corresponding relationship between the end point and the starting point is determined by the evaluation element identifier of MARK: "10".

[0075] In order t...

example 3

[0078] N: 30, MTYPE: "Rad", MARK: "5", DE: "-0.02", UE: "0.02", SPD: "3", KFACT: "cur"

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com