Method for testing foil resistivity

A test method and resistivity technology, applied in the direction of measuring resistance/reactance/impedance, measuring device, analyzing materials, etc., to achieve the effect of simple and reliable test method, high data accuracy, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

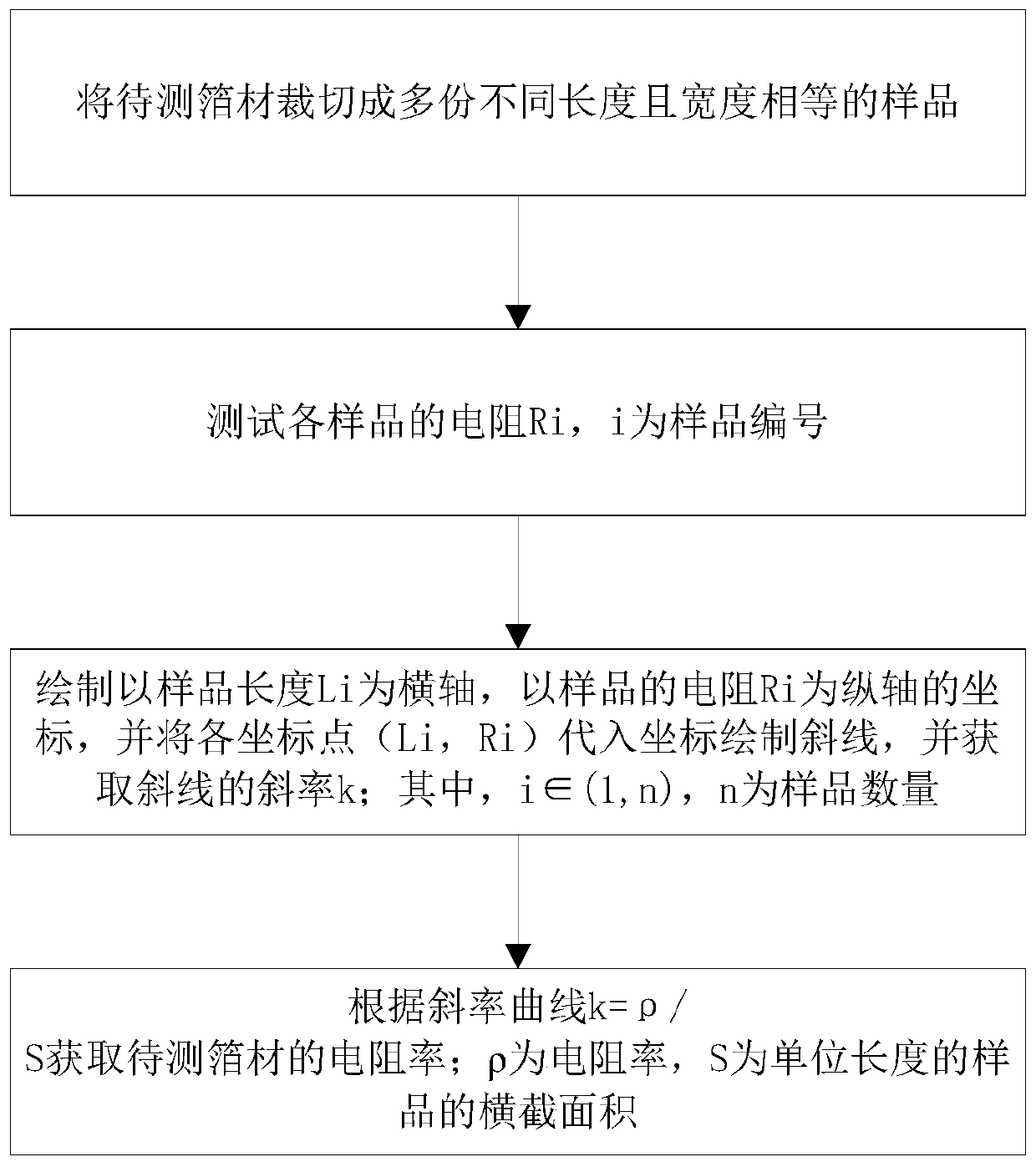

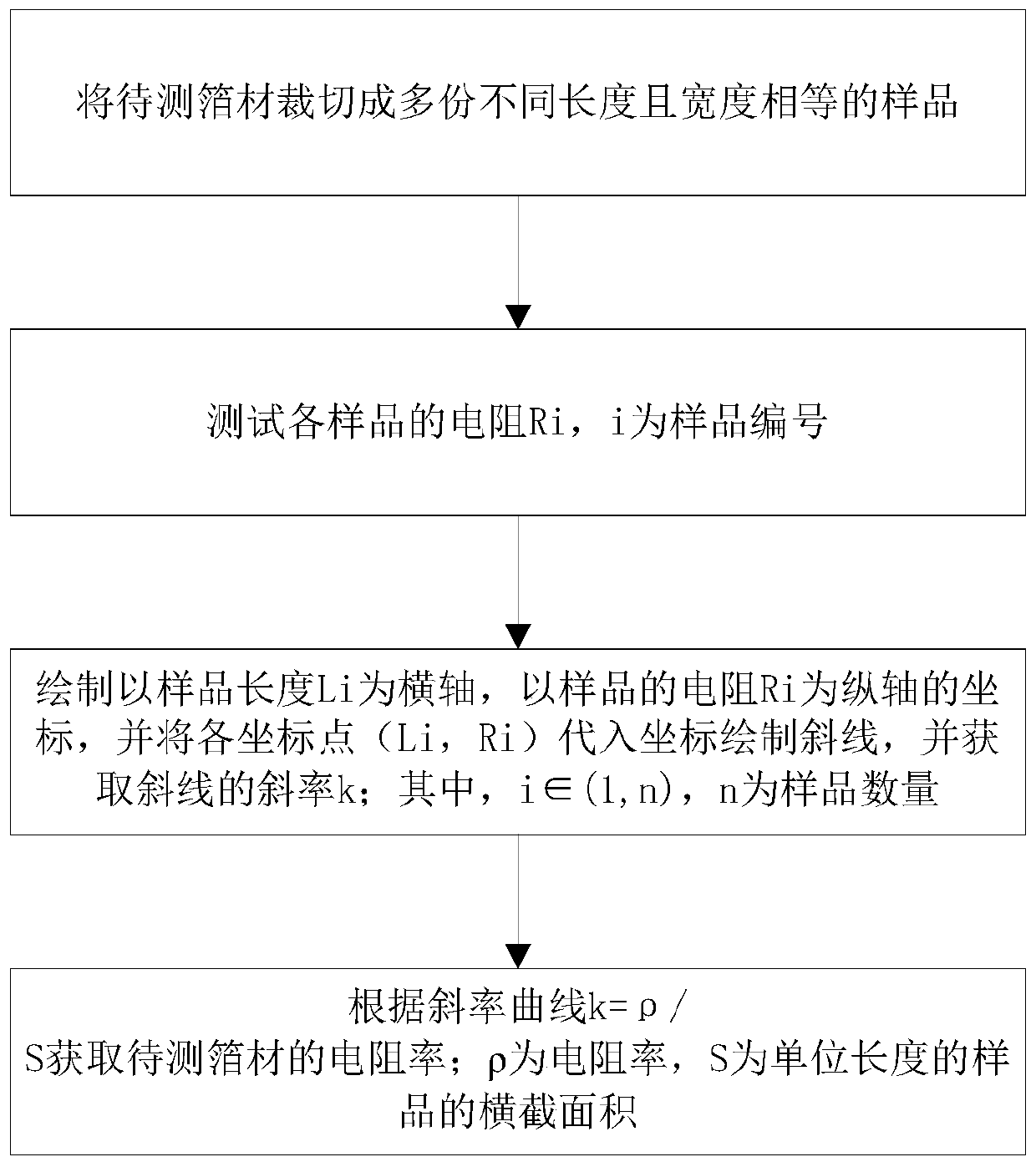

Method used

Image

Examples

Embodiment 1

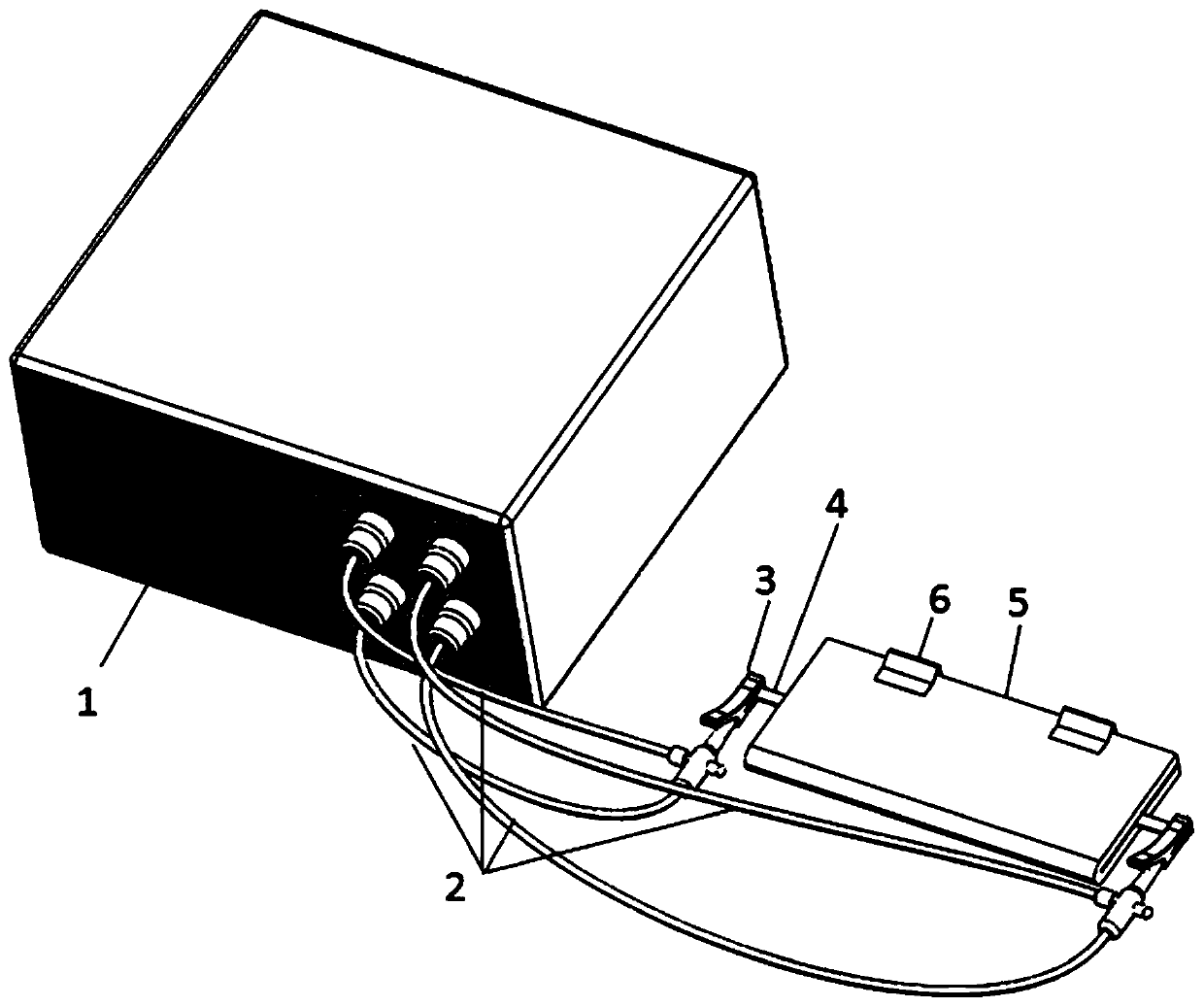

[0035] In this embodiment, the resistivity of an aluminum foil is tested by this method. Before the test, gently wipe the surface of the aluminum foil with absolute ethanol to remove oil stains on the surface of the aluminum foil. After the ethanol volatilizes naturally, use a foil sampler to cut the aluminum foil into strips with a width of 5mm. Using a foil sampler can ensure that the sample Cut evenly without burrs. Then use a utility knife to cut the strip sample into samples with lengths of 25cm, 20cm, 15cm, and 10cm respectively, and use insulating plates or clamps to fix the samples to prevent the samples from bending and breaking. Connect the fixed samples to the electrodes at both ends of the electrochemical workstation, test the impedance of the samples with lengths of 25cm, 20cm, 15cm, and 10cm in turn, and directly read the intersection points of the curve and the Z-axis from the impedance spectrogram, which is the different lengths under the foil resistors.

[0...

Embodiment 2

[0041] To test the resistivity of a certain type of copper foil, the resistivity of a certain type of copper foil was tested by the same method as the aluminum foil resistivity test, and the specific data are summarized in Table 2. From the data in Table 2, we can see that after two parallel sample tests, the results are consistent. The average resistivity of the copper foil obtained by the test is 2.21×10 -8 Ω m, close to the resistivity of pure copper 1.75×10 -8 Ω·m, indicating that the test method provided by the present invention is accurate and reliable.

[0042] Specifically, in the above two embodiments, for the convenience of calculation, the lengths of each sample are successively increased to form an arithmetic sequence.

[0043] Table 2: Example 2 sample test data table

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com