Vehicle painting rocker panel glue visual inspection system and method

A visual inspection and skirting technology, which is used in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of unstable communication, delay in information transmission, poor stability, etc., to avoid interface complexity and reduce labor costs. , easy to analyze and verify the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

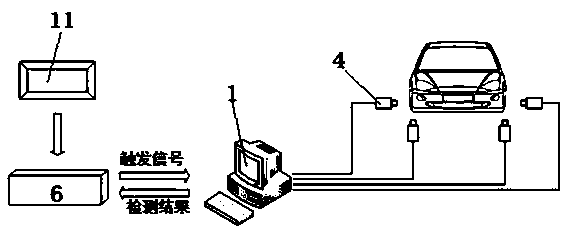

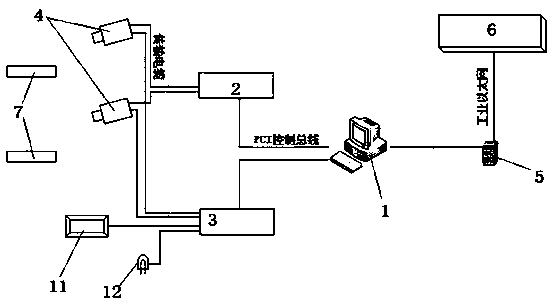

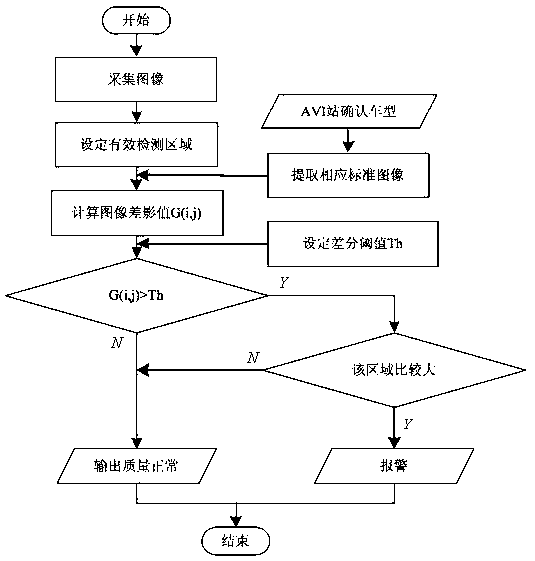

[0039] Please see attached figure 1 and attached figure 2 , a visual inspection system for automotive coating skirt glue, including an industrial computer 1, an image processor module 2, a high-speed I / O (input / output) module 3, a camera module 4, and an OPC server module 5 (OPC: OLE for Process Control , which is the OLE industry standard for process control; OLE: Object Linking and Embedding, that is, object connection and embedding) and programmable logic controller (PLC) 6; one end of the OPC server module 5 communicates with the programmable logic controller through Ethernet 6 connection, the other end of the OPC server module 5 is connected to the industrial computer 1 through Ethernet, the programmable logic controller 6 sends a trigger signal to the industrial computer 1 through the OPC server module 5, and the industrial computer 1 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com