Aerogel composite glass and manufacturing method thereof

A combination of glass and manufacturing method technology, applied in heat preservation, heat insulation, lighting, sound insulation materials, and visual fields, can solve the problems of easy damage, difficult marketing, and no visual effect, so as to reduce secondary radiation and improve heat dissipation. The effect of workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] The airgel composite glass was prepared by the following steps:

[0109] (1) Mix ethyl orthosilicate, ethanol, deionized water, and hydrochloric acid in a molar ratio of 1:8:2:1×10 -3 Mix and stir evenly, after fully hydrolyzed, then according to the molar ratio of ethyl orthosilicate and ammonia water 1:2.5×10 -3 Add ammonia water, mix and stir to obtain sol;

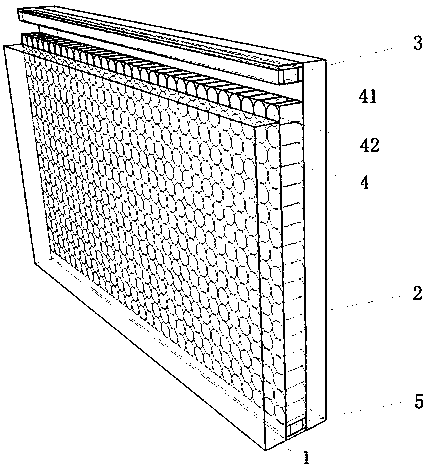

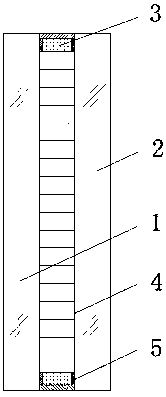

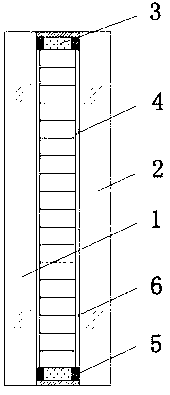

[0110] (2) Cast the prepared sol into the through hole of the honeycomb core 41 pre-placed in the mold, wherein the shape of the through hole is a cylinder, the diameter of the hole is 10mm, the height is 9mm, and the thickness of the hole wall is 0.1mm. , after being gelled, the mold is demoulded, and the honeycomb core 41 containing the gel is directly put into a drying kettle for carbon dioxide supercritical drying to obtain a composite honeycomb core 4;

[0111] (3) Place the composite honeycomb core 4 between two pieces of float glass (1, 2), use butyl sealant 5 and bridge-breaking aluminum spacer frame ...

Embodiment 2

[0114] (1) Mix ethyl orthosilicate, ethanol, deionized water, and hydrochloric acid in a molar ratio of 1:10:6:1.8×10 -3 Mix and stir evenly, after fully hydrolyzed, then according to the molar ratio of ethyl orthosilicate and ammonia water 1:3.6×10 -3 Add ammonia water, mix and stir to obtain sol;

[0115] (2) Cast the prepared sol into the through hole of the honeycomb core 41 pre-placed in the mold, wherein the shape of the through hole is a regular hexagonal prism with a diameter of 20 mm, a height of 12 mm, and a wall thickness of 0.5 mm. After being gelled, the mold is demoulded, and the honeycomb core 41 containing the gel is directly put into a drying kettle for carbon dioxide supercritical drying to obtain a composite honeycomb core 4;

[0116] (3) Place the composite honeycomb core 4 between two pieces of float glass (1, 2), use butyl sealant 5 and bridge-breaking aluminum spacer frame 3 to bond and seal around the composite honeycomb core 4, and reuse The silicon...

Embodiment 3

[0119] (1) Mix ethyl orthosilicate, ethanol, deionized water, and hydrochloric acid in a molar ratio of 1:3:2:0.8×10 -3 Mix and stir evenly, after fully hydrolyzed, then according to the molar ratio of ethyl orthosilicate and ammonia water 1:1.6×10 -3 Add ammonia water, mix and stir to obtain sol;

[0120] (2) Cast the prepared sol into the through hole of the honeycomb core 41 pre-placed in the mold, wherein the shape of the through hole is a regular square prism, the aperture is 80 mm, the height is 40 mm, and the thickness of the hole wall is 1 mm. , after being gelled, the mold is demoulded, and the honeycomb core 41 containing the gel is directly put into a drying kettle for carbon dioxide supercritical drying to obtain a composite honeycomb core 4;

[0121] (3) Place the composite honeycomb core 4 between two transparent polycarbonate plates (1, 2), and use epoxy resin sealant 5 and fiber-reinforced plastic spacer frame 3 to bond and seal around the composite honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

| Heat transfer coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com