High-tolerance textured lacquer and preparation method thereof

A technology of properties and fungicides, applied in the field of high-tolerance textured paint and its preparation, can solve the problem that exterior wall textured paint is not suitable for interior walls, etc., achieve uniform and stable mixing of paint liquid, good brushing effect, and avoid sedimentation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

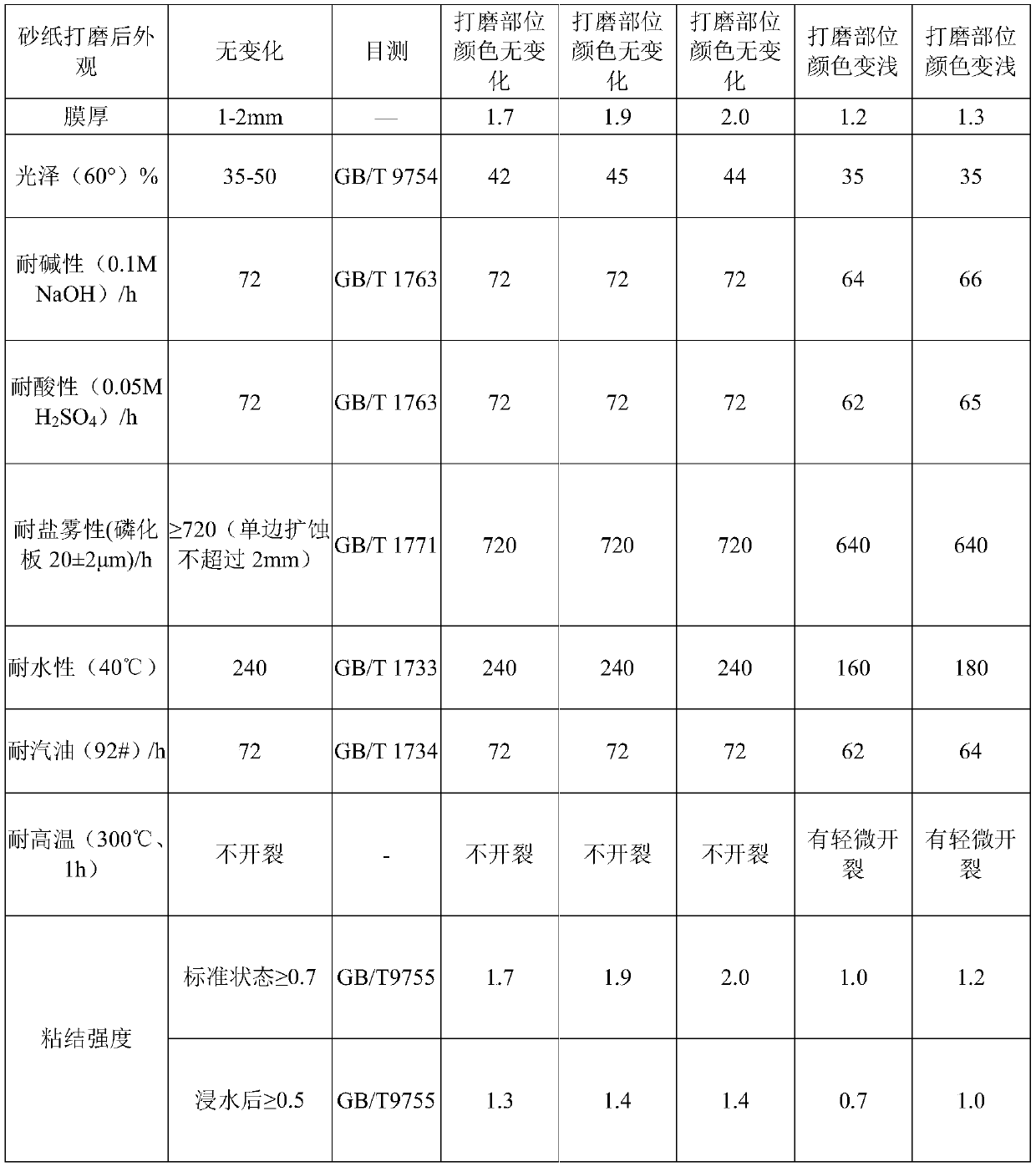

Embodiment 1

[0024] The embodiment of the present invention provides a high-tolerant varnish, including the following raw materials in proportions by weight: 10 parts of deionized water, 0.2 parts of cellulose, 0.4 parts of a fungicide, 0.3 parts of a dispersant, and 0.3 parts of a pH regulator. 5 parts of filler, 10 parts of emulsion, 5 parts of potassium silicate, 0.2 parts of antifreeze, 0.5 parts of coalescent, 0.2 parts of defoamer, 67.5 parts of snow white, 0.3 parts of diatomaceous earth and 0.2 parts of thickener.

[0025] The cellulose is 250HBR, the bactericide is a mixture of MERGAL 786 and MERGAL K9N with a mass ratio of 1:1, the dispersant is OROTAN 731A, the pH regulator is AMP-95, the filler is heavy calcium powder with a particle size of 800 mesh, and the emulsion is RS- 996AD, the antifreeze is propylene glycol, the coalescent is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, the defoamer is FoamStarA10, and the thickener is ACRYSOLTT-935.

[0026] The preparation method...

Embodiment 2

[0029] The embodiment of the present invention provides a high-tolerant varnish, which includes the following raw materials in parts by weight: 8 parts of deionized water, 0.1 part of cellulose, 0.2 parts of bactericide, 0.4 parts of dispersant, 0.1 part of pH regulator, 4 parts of filler, 12 parts of emulsion, 4 parts of potassium silicate, 0.2 part of antifreeze, 0.6 part of film-forming aid, 0.1 part of defoamer, 69 parts of snow white, 0.5 part of diatomaceous earth and 0.5 part of thickener.

[0030] The cellulose is HS10W, the bactericide is a mixture of MERGAL 786 and MERGAL K9N with a mass ratio of 1:1, the dispersant is OROTAN 731A, the pH regulator is AMP-95, the filler is heavy calcium powder with a particle size of 800 mesh, and the emulsion is ZS- 6408, the antifreeze is propylene glycol, the coalescent is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, the defoamer is FoamStar A10, and the thickener is ACRYSOL TT-935 .

[0031] The preparation method of above-m...

Embodiment 3

[0034] The embodiment of the present invention provides a high-tolerant varnish, which includes the following raw materials in proportions by weight: 9 parts of deionized water, 0.3 parts of cellulose, 0.3 parts of bactericide, 0.5 parts of dispersant, 0.2 parts of pH regulator, and fillers 3 parts, 10 parts of emulsion, 6 parts of potassium silicate, 0.3 parts of antifreeze, 0.4 parts of film-forming aid, 0.3 parts of defoamer, 68.3 parts of snow white, 0.4 parts of diatomaceous earth and 0.3 parts of thickener.

[0035] The cellulose is 250HBR, the bactericide is a mixture of MERGAL 786 and MERGAL K9N with a mass ratio of 1:2, the dispersant is OROTAN 731A, the pH regulator is butyl ethanolamine, the filler is heavy calcium powder with a particle size of 800 mesh, and the emulsion is RS- 996AD, the antifreeze is propylene glycol, the coalescent is 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, the defoamer is FoamStar A10, and the thickener is ACRYSOLTT-935.

[0036] The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com