Ammonia-free preservative for natural fresh latex

A fresh latex, natural technology, applied in the field of natural fresh latex ammonia-free preservatives, can solve problems such as affecting product safety, environmental pollution, affecting latex stability and vulcanization performance, etc., and achieves low raw material cost, low fatty acid value, and good preservation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

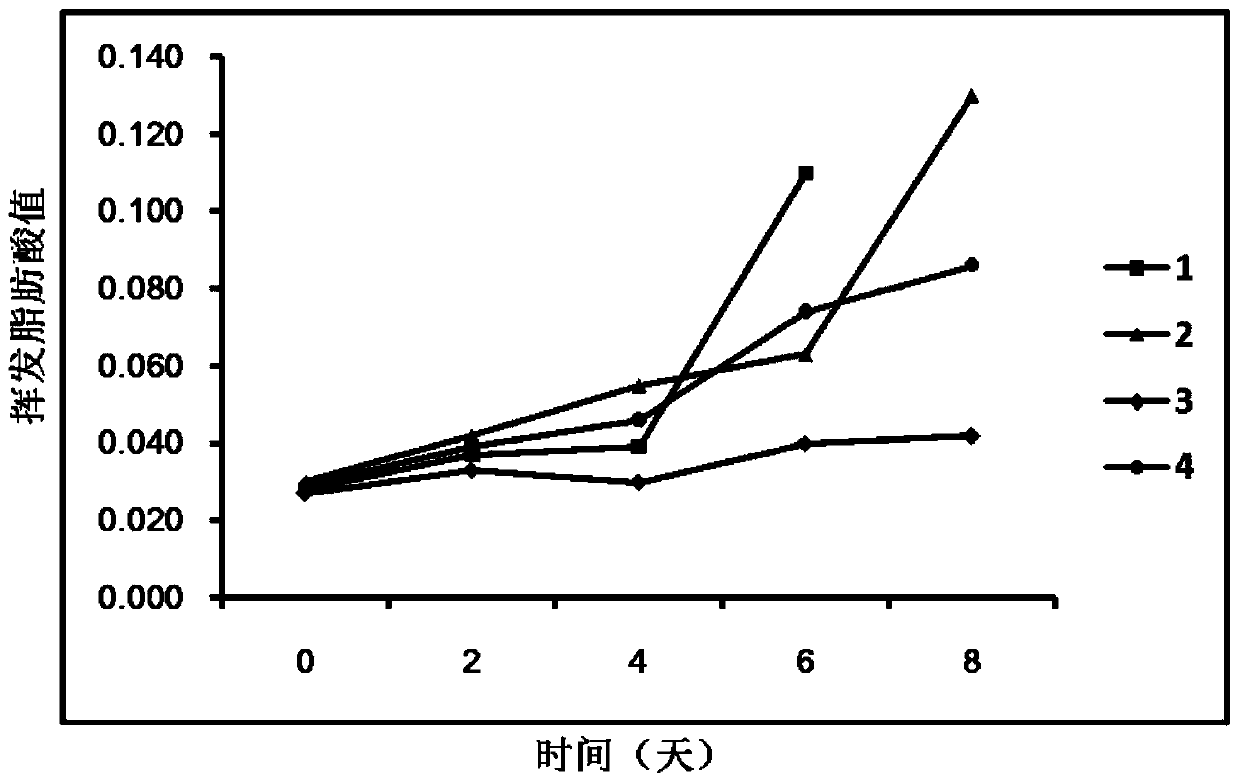

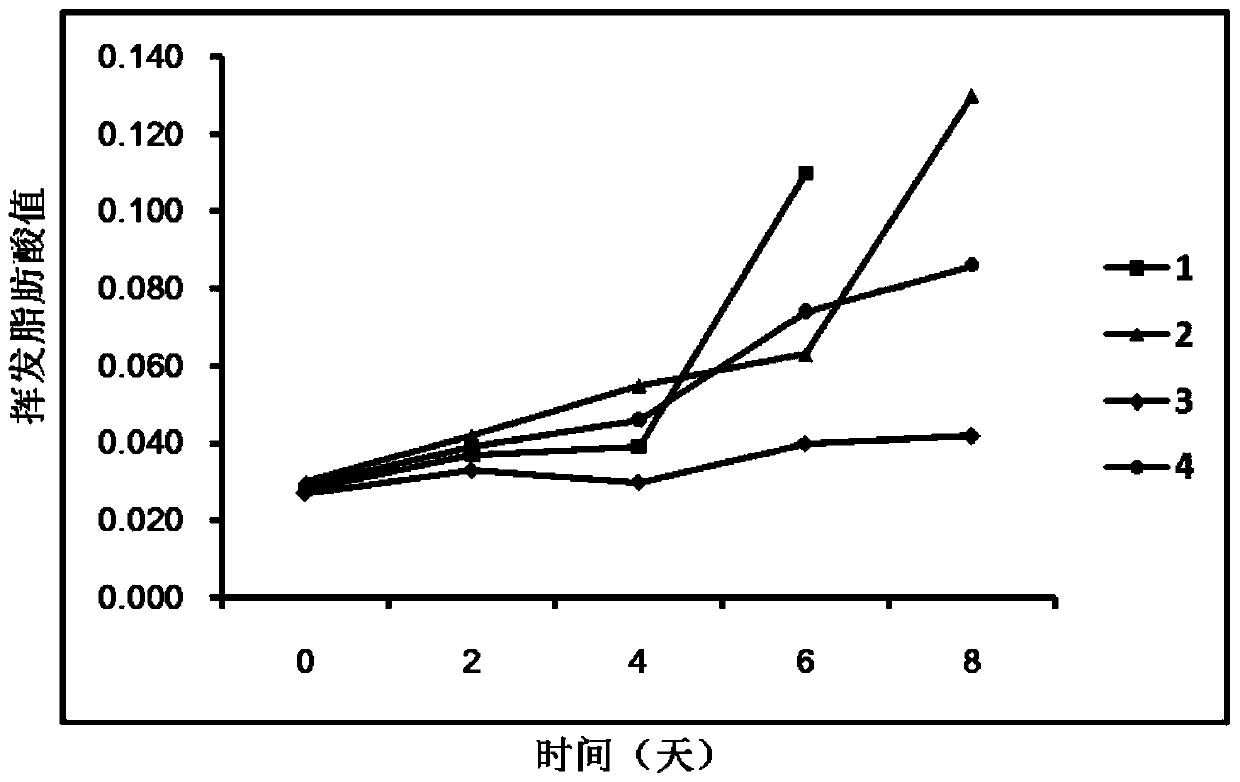

[0047] Example 1 provides a method for the preservation of natural fresh rubber latex without ammonia, which mainly includes the following steps: separately configure the bactericide and alkaline stabilizer in the preservation system into a 10wt% aqueous solution, and add the weight of natural rubber latex to the fresh natural rubber latex in advance. 0.1wt% alkaline stabilizer solution, after the fresh latex is taken back to the rubber collecting station (that is, adding the bactericide after adding the stabilizer for about 8-9 hours), add the bactericide of 0.1% by weight of the natural rubber latex, and stir and mix thoroughly After that, let it stand for storage, and regularly test the volatile fatty acid value of natural rubber latex.

[0048] The bactericide consists of equal weight of 2-bromo-2-nitro 1,3-propanediol (CAS number: 52-51-7), sodium dehydroacetate, BHT, cassone, DMDMH, BIT and sodium tripolyphosphate Composition; The alkaline stabilizer is disodium hydrogen ph...

Embodiment 2

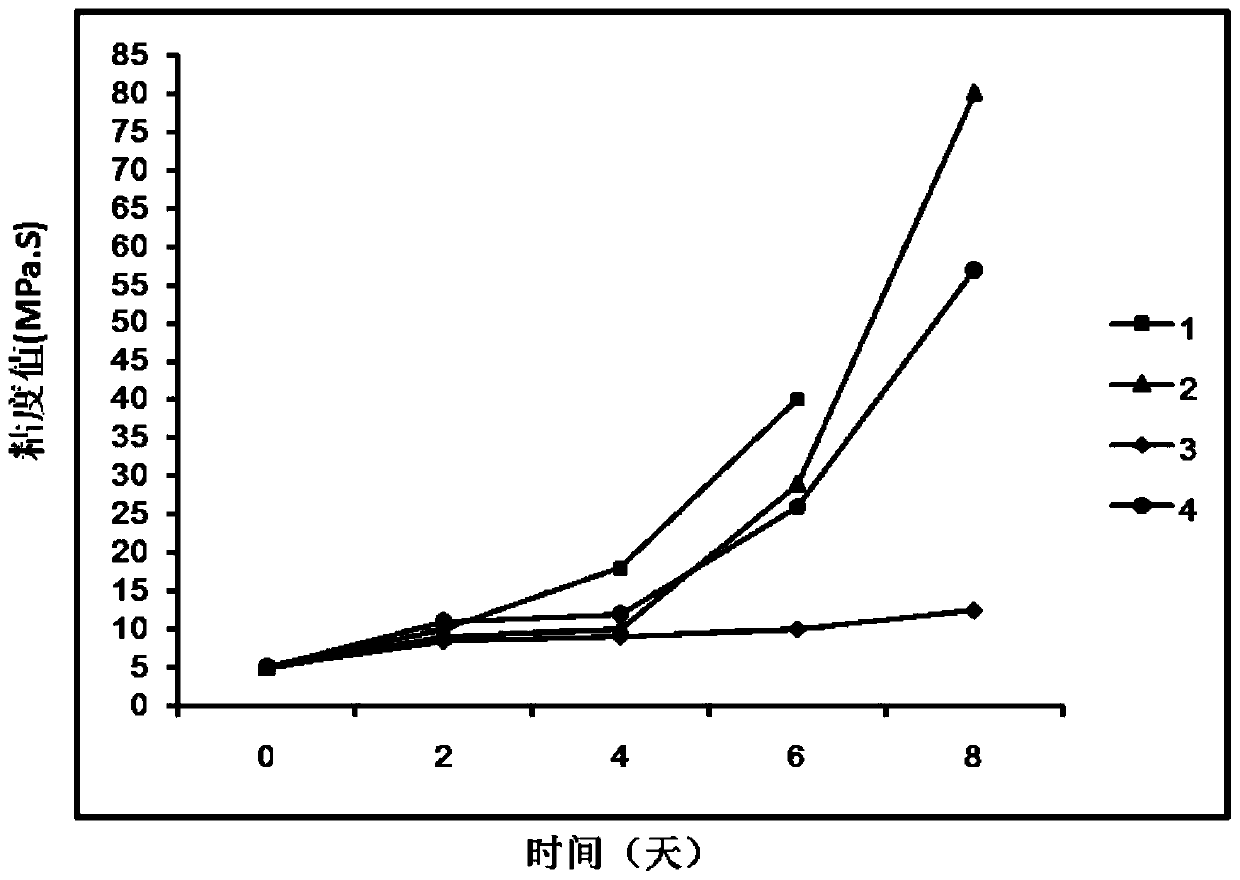

[0050] Example 2 provides a ammonia-free preservation method for natural fresh rubber latex, which mainly includes the following steps: configure the alkaline stabilizer in the preservation system into a 10wt% aqueous solution, and add 0.1wt% of the natural rubber latex to the fresh natural rubber latex in advance. Bactericide solid, after the fresh latex is taken back to the rubber collection station (that is, the stabilizer is added after adding the bactericide for about 8-9 hours), add the natural rubber latex weight 0.1wt% of the alkaline stabilizer, stir and mix thoroughly, and store it statically , And regularly check the volatile fatty acid value and viscosity value of natural rubber latex.

[0051] The bactericide consists of equal weight of 2-bromo-2-nitro 1,3-propanediol (CAS number: 52-51-7), sodium dehydroacetate, BHT, cassone, DMDMH, BIT and sodium tripolyphosphate Composition; The alkaline stabilizer is disodium hydrogen phosphate.

Embodiment 3

[0053] Example 3 provides a ammonia-free preservation method for natural fresh rubber latex, which mainly includes the following steps: separately configure the bactericide and alkaline stabilizer in the preservation system into a 10wt% aqueous solution, and add the weight of natural rubber latex to the fresh natural rubber latex in advance. 0.12wt% of the bactericide, after the fresh latex is taken back to the rubber collection station (that is, the bactericide is added for about 8-9 hours and then the stabilizer is added), add the natural rubber latex weight 0.1wt% of the alkaline stabilizer, mix well and shake well After that, let it stand for storage, and regularly check the volatile fatty acid value and viscosity value of natural rubber latex.

[0054] The bactericide consists of equal weight of 2-bromo-2-nitro 1,3-propanediol (CAS number: 52-51-7), sodium dehydroacetate, BHT, cassone, DMDMH, BIT and sodium tripolyphosphate Composition; The alkaline stabilizer is disodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com