Method for treating refractory organic pollutants in wastewater by dithionite-activated persulfates

A technology of hydrosulfite and activated persulfate, applied in water pollutants, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve the problems that hinder the wide application of persulfate technology and lack practical application value and potential , the problem of high energy consumption of persulfate technology, to achieve the effect of large application potential, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

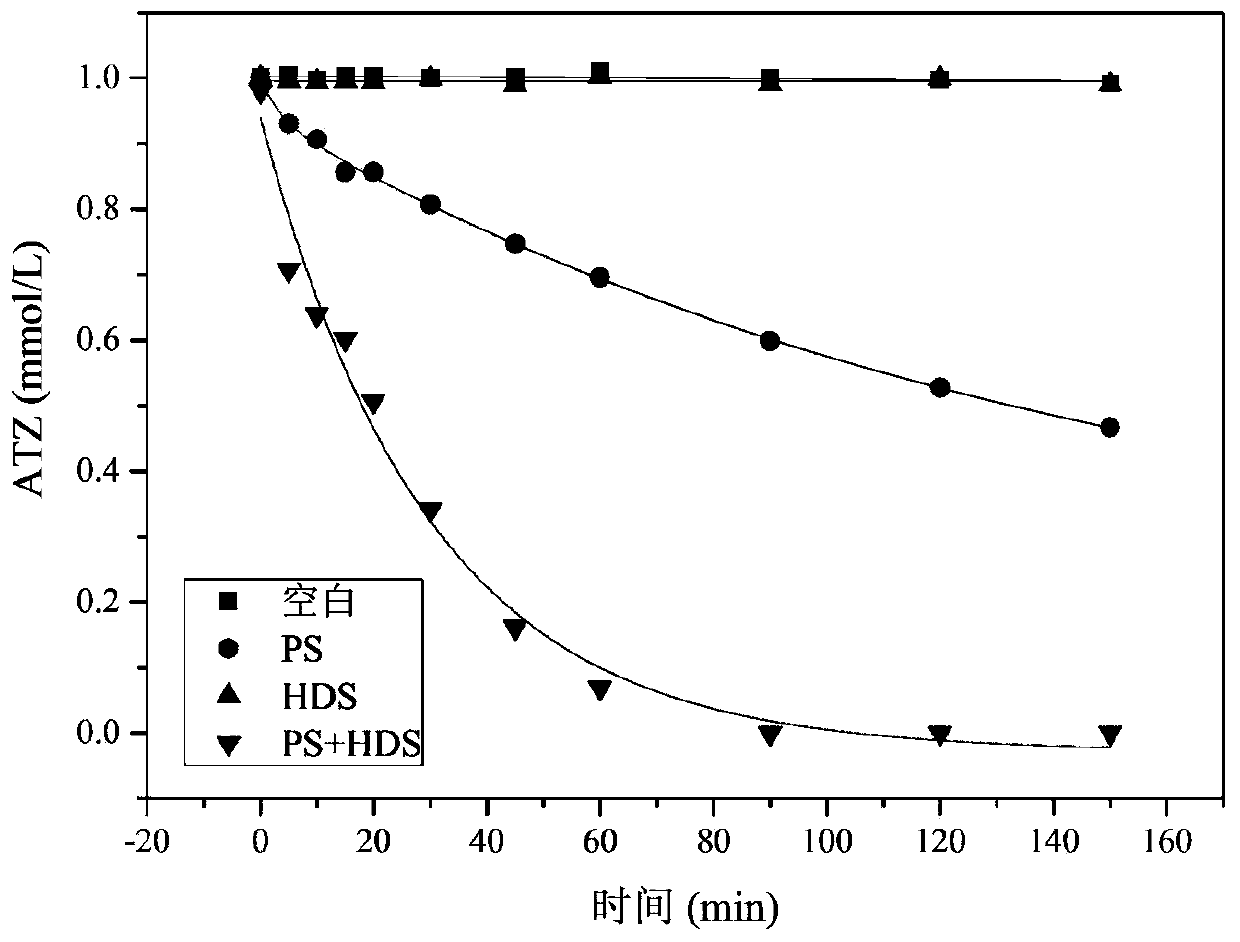

[0033] Example 1: Dithionite activates persulfate to degrade atrazine-containing organic wastewater

[0034] Take four opaque reaction containers, add organic waste water containing 1 μmol / L atrazine to each of them, the pH in the reactors is about 7.2, and the reaction temperature is 30 ° C. At the same time, the four reactors are stirred slowly to make them Uniform response;

[0035] In reaction vessel 1, add sodium dithionite solution so that its concentration is 0.2mmol / L, add potassium persulfate solution into reaction vessel 2 and make its concentration 0.5mmol / L, in reaction vessel 3, add sodium dithionite solution and Potassium persulfate solution made its concentration 0.2mmol / L and 0.5mmol / L respectively, and reactor 4 was used as a blank control, and the reaction was basically completed after continuing for 1h, and then the remaining concentration of atrazine in the wastewater was detected, and the detection results were shown in the following table Shown:

[0036...

Embodiment 2

[0039] Example 2: Dithionite activates persulfate to degrade bisphenol A-containing organic wastewater

[0040] Take four opaque reaction containers, add organic waste water containing 2 μmol / L bisphenol A to each of them, the pH in the reactors is about 4.0, and the reaction temperature is 30°C. At the same time, stir the four reactors at a slow speed to make them uniform. reaction;

[0041]Add sodium dithionite solution to reaction vessel 1 to make its concentration 0.5mmol / L, add potassium persulfate solution to reaction vessel 2 to make its concentration 0.5mmol / L, add sodium dithionite solution to reaction vessel 3 at the same time and potassium persulfate solution so that the concentration is 0.5mmol / L, reactor 4 is used as a blank control, and the reaction is basically completed after continuing for 0.5h, and then the residual concentration of bisphenol A in the wastewater is detected, and the detection results are shown in the following table:

[0042] Table 2 Dithion...

Embodiment 3

[0045] Example 3: Dithionite activates different concentrations of persulfate to degrade atrazine-containing organic wastewater

[0046] Take six opaque reaction containers, add organic waste water containing 1 μmol / L atrazine to each of them, the pH in the reactors is about 7.2, and the reaction temperature is 30 ° C. At the same time, the six reactors are stirred slowly to make them Uniform reaction; add sodium dithionite solution and potassium persulfate solution to reaction vessel 1 at the same time to make the concentration respectively 0.2mmol / L and 0.05mmol / L, add sodium dithionite solution and potassium persulfate solution to reaction vessel 2 Make the concentrations respectively 0.2mmol / L and 0.1 mmol / L, add sodium dithionite solution and potassium persulfate solution to the reaction vessel 3 at the same time so that the concentration is 0.2 mmol / L, add dithionite solution to the reaction vessel 4 at the same time Sodium sulfite solution and potassium persulfate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com