A full liquid phase hydrogenation technology

A liquid-phase hydrogenation technology, applied in the field of hydrogenation stations, can solve the problems of high transportation and storage costs of hydrogenation stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

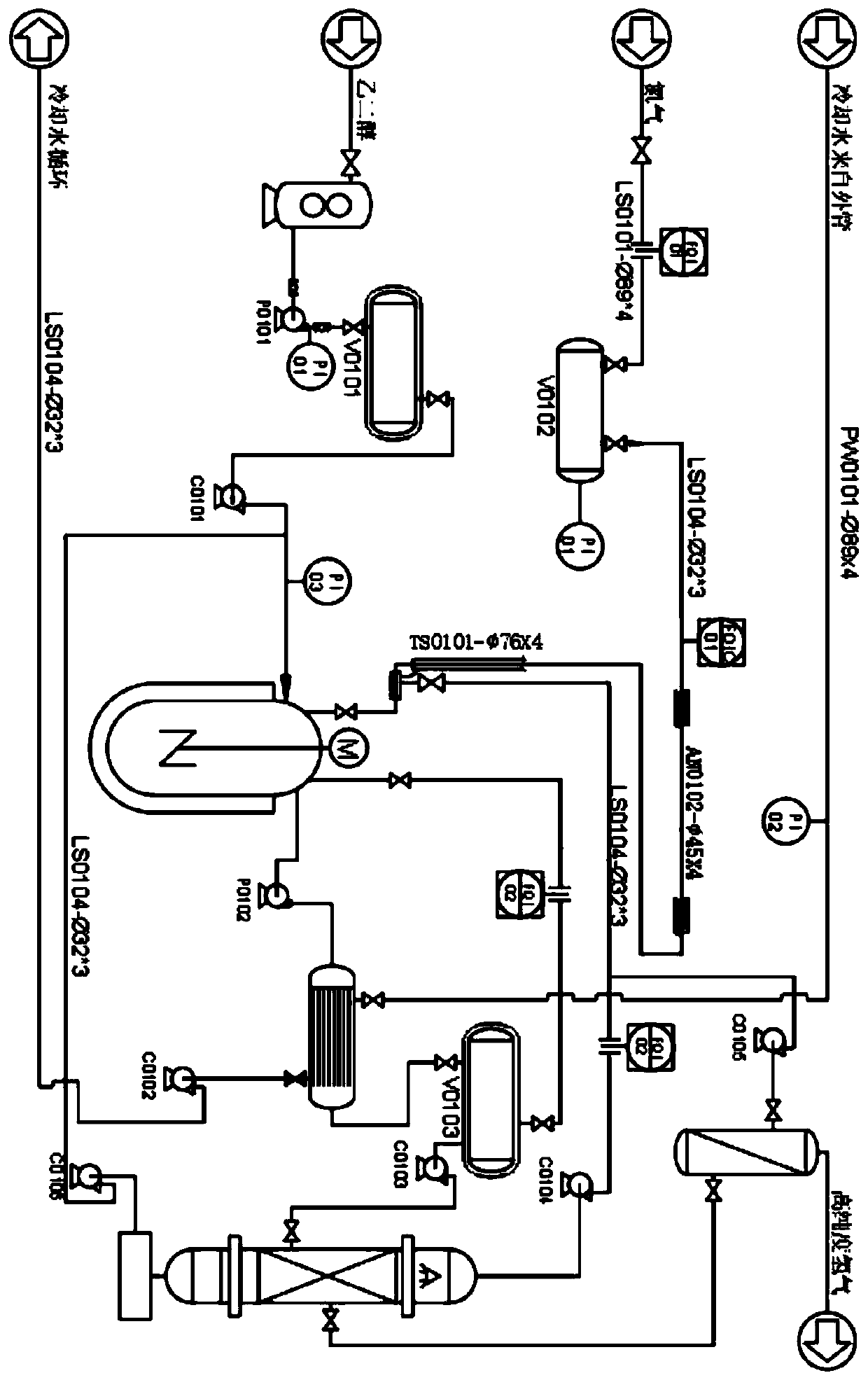

[0027] A full liquid phase hydrogenation technology, comprising the following steps;

[0028] S1. The ethanol raw material delivery vehicle delivers the ethanol raw material to the ethanol raw material storage tank set up inside the hydrogenation station, and transports the ethanol raw material to the raw material buffer preheating tank;

[0029] S2. Add the hydrogen-reduced catalyst to the high-pressure reactor set up in the hydrogenation station, and open the control valve, inject the ethanol raw material in the raw material buffer preheating tank into the high-pressure reactor, and open the gas path valve to feed the high-pressure reactor Add nitrogen to the reactor, and raise the pressure to 2.5-3MPa, and control the jacket heating device at the bottom of the high-pressure reactor through an external circuit to raise the temperature to 200-250°C, and continue to stir;

[0030] S3. During the reaction process, keep stirring for 2.5-3.5 hours. After the gas phase in the high...

Embodiment 2

[0043] Embodiment 2: Based on Embodiment 1 but different;

[0044] The gas product after gas-liquid separation is measured by Agilent 7890A gas chromatograph, chromatographic column 5A molecular sieve (2m, φ3mm) packed column and PorapakQ (3m) packed column, nitrogen is carrier gas, hydrogen is measured by TCD detector, CO 2 , CO, CH 4 And other alkanes are detected by the FID detector after being converted by the reformer. The column temperature is 50°C, the injector temperature is 100°C, the reformer temperature is 380°C, and the detector temperature is 100°C.

[0045] The liquid phase product after gas-liquid separation was determined by Agilent 7890A gas chromatograph, the chromatographic column was DB-WAX (60m, φ0.53mm), and the carrier gas was helium. The initial column temperature was 40°C, raised to 240°C at a heating rate of 10°C / min, kept for 8 minutes, and quantified by the internal standard method, using ethylene glycol-butyl ether as the internal standard. The ...

Embodiment 3

[0046] Embodiment 3: based on embodiment 1 and 2 but different;

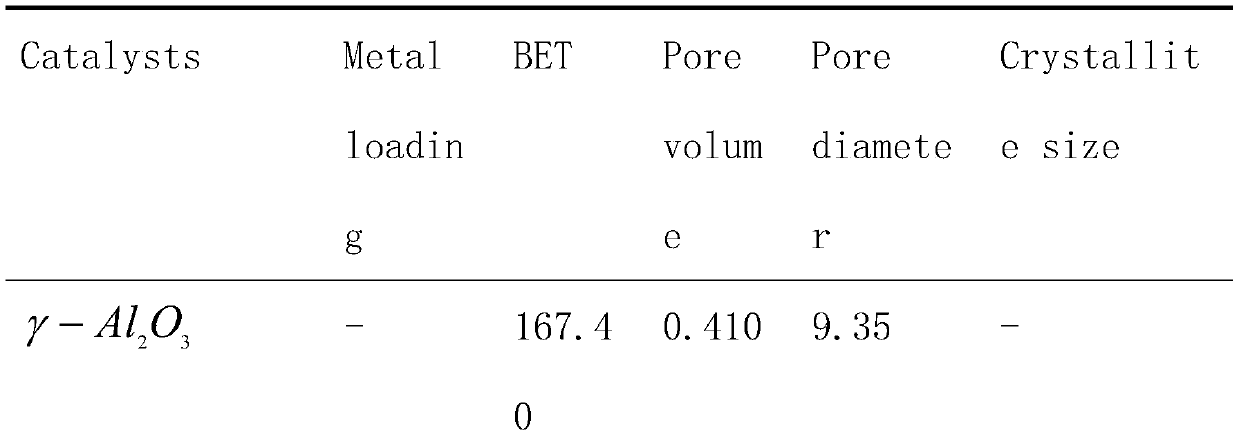

[0047] Pd / γ-Al is given in the table below 2 o 3 , PdNi / γ-Al 2 o 3 and Ni / γ-Al 2 o 3 The basic physical structure properties of the three catalysts, the three catalysts are prepared by the equal volume impregnation method, the theoretical metal loading is 3wt%, and the actual loading is measured by ICP-AES. As shown in the table below, before loading γ-Al 2 o 3 The specific surface area of the carrier is as high as 167.40m 2 / g, the pore volume and average pore diameter are 0.41cm 3 / g and 9.35nm. After metal loading, it is found that no matter what kind of metal is loaded, although the actual loading rate is below 3wt% as determined by ICP-AES,

[0048] But γ-Al 2 o 3 The specific surface area of the carrier decreased significantly from the initial

[0049] 167.40m 2 / g drops to 124-133m 2 / g, the pore volume is reduced to pure γ-Al 2 o 3 Half of the carrier, the average pore diameter also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com