Acidic solid catalyst used for catalyzing conversion of fructose into 2,5-dimethylfuran in one step

A solid catalyst, dimethylfuran technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, catalytic reaction, etc., can solve problems such as high separation cost, high boiling point, etc. The effect of excellent stability, avoiding high energy consumption and inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] As mentioned earlier, the current production of 2,5-dimethylfuran on biomass is mainly prepared from 5-hydroxymethylfurfural (HMF) by hydrogenolysis. However, since HMF needs to be separated and purified after the dehydration reaction of sugar compounds, its extremely high boiling point leads to high separation costs, which has become an important factor limiting this process route. For this reason, the present inventors conducted extensive research on the process of producing 2,5-dimethylfuran based on biomass.

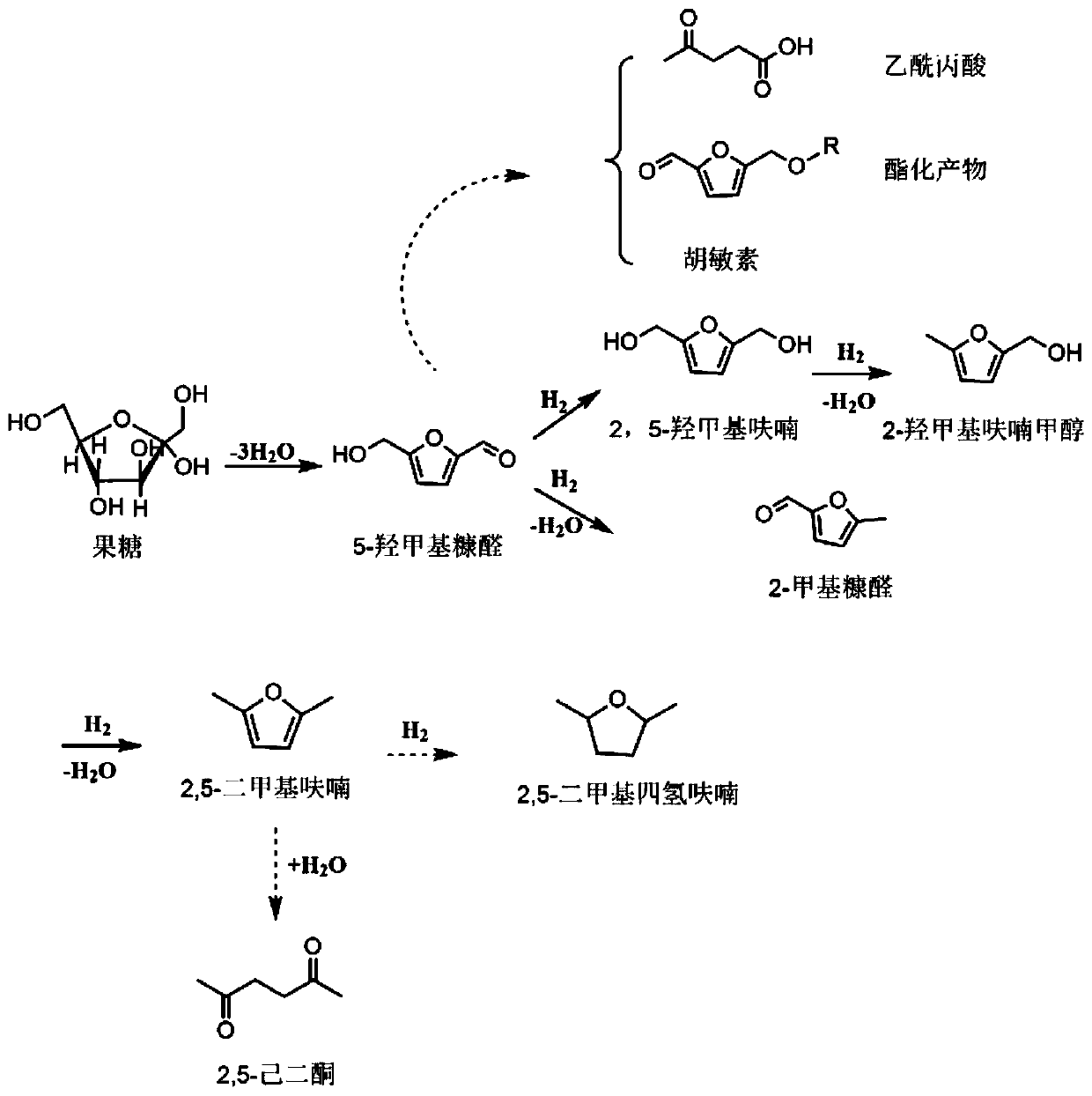

[0064] The reaction process of converting fructose into 2,5-dimethylfuran in one step is as follows: figure 1 shown. From Figure 1 It can be seen that fructose undergoes dehydration reaction under acidic conditions to first obtain HMF, and then HMF and hydrogen source obtain 2,5-dimethylfuran under the action of the hydrogenation reaction center, so the requirements for the catalyst are 1) acidity; 2) It has hydrogenation sites.

[0065] Such as figure 1...

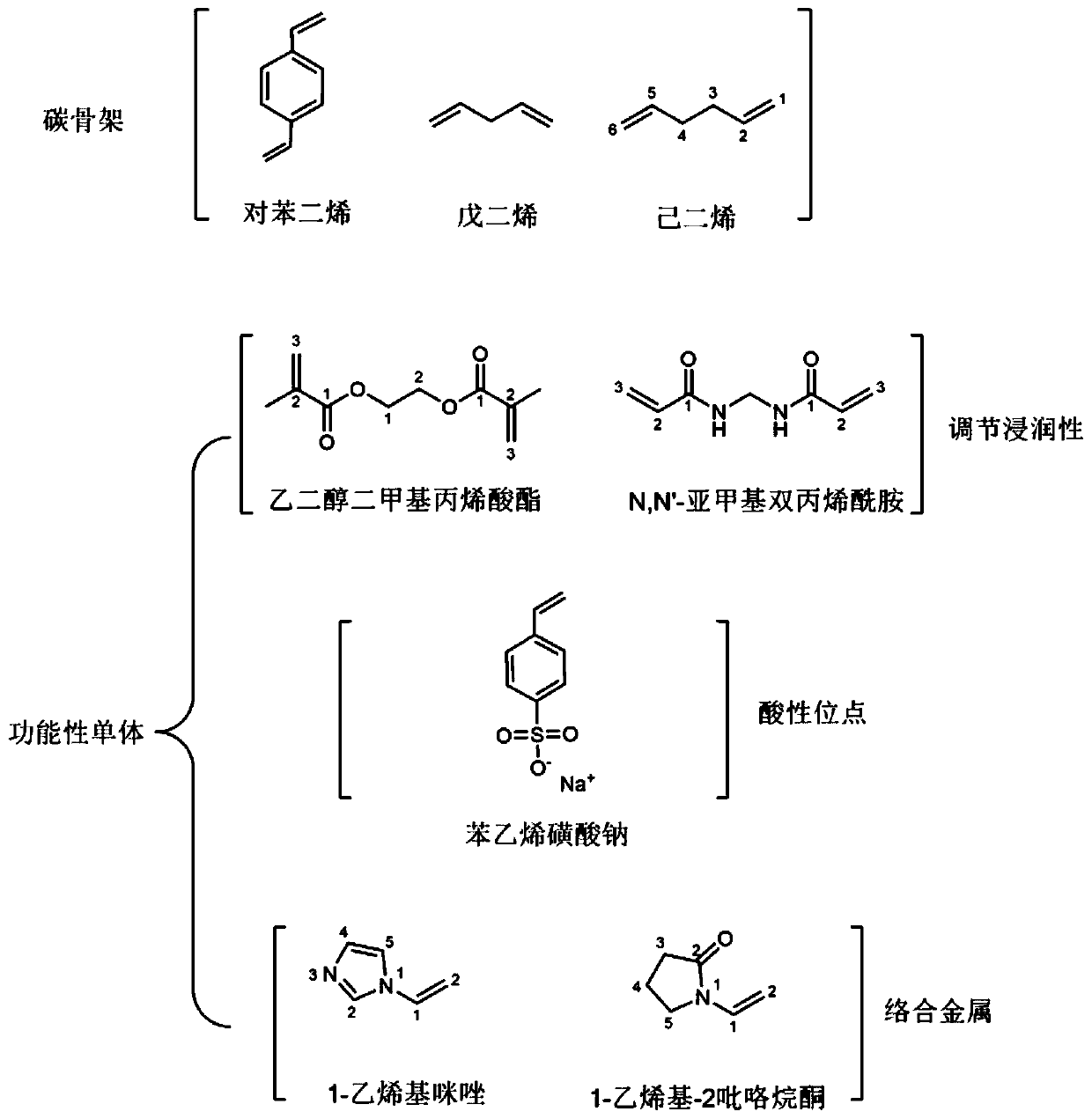

Embodiment 1

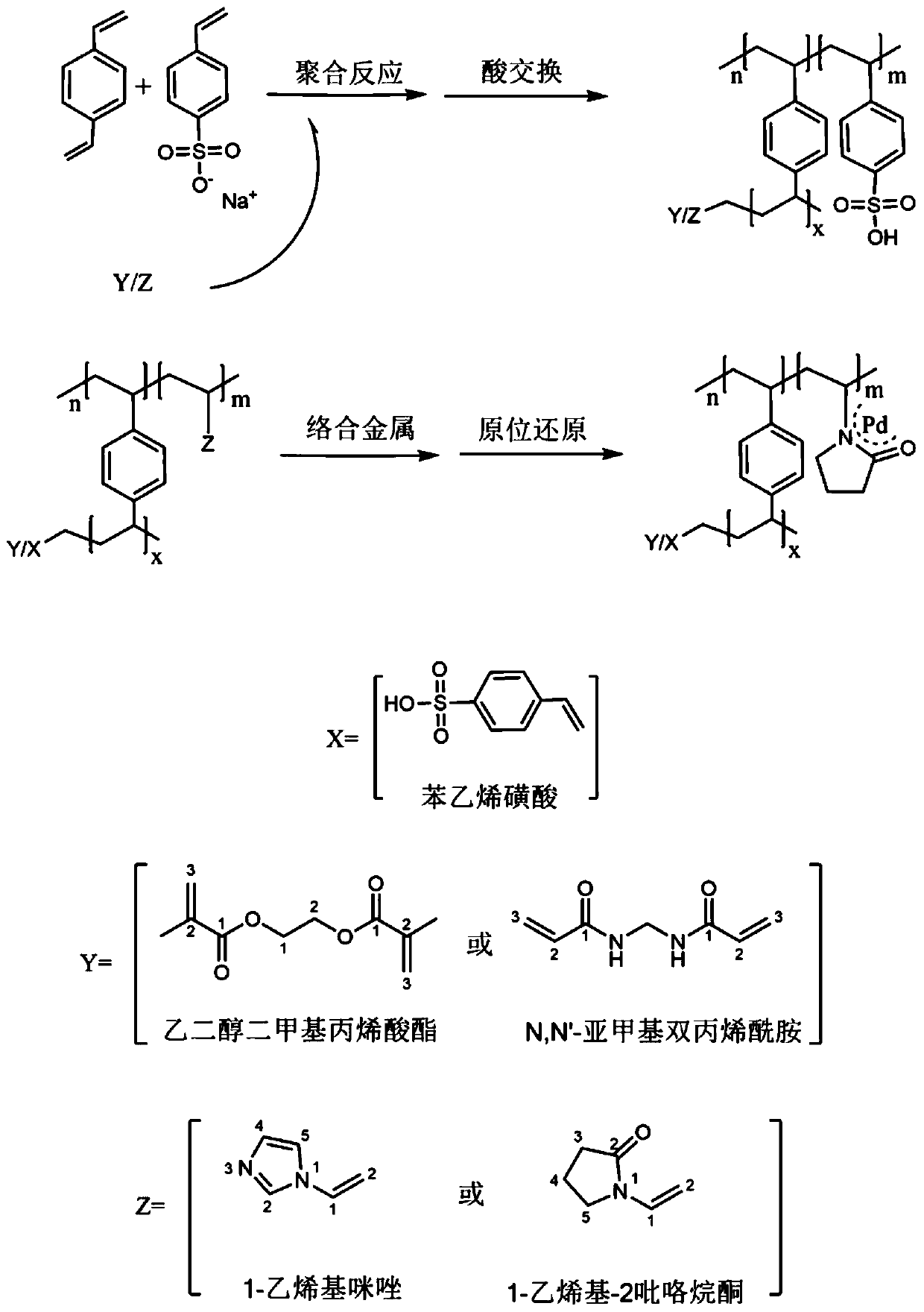

[0130] (1) Add divinylbenzene (2.0g) and azobisisobutyronitrile (0.05g) into a mixed solution of THF (20mL) and water (2mL), and then add sodium p-styrenesulfonate (0.16 g) and 1-vinyl-2-pyrrolidine (0.23 g), after stirring at room temperature for 3 hours, a mixed solution of the precursor of the porous polymer carrier was obtained.

[0131] (2) The mixed solution of the precursor of the porous polymer carrier was transferred to an autoclave and crystallized at 373 K for 24 hours. After evaporating the solvent at room temperature, the precursor of the multifunctional porous polymer was obtained.

[0132] (3) Take 1 g of the porous polymer carrier and disperse it in a mixed solution (1 mol / L) of sulfuric acid and ethanol, and perform acid exchange treatment for 24 hours; after drying at room temperature, an acidic porous polymer material is obtained.

[0133] (4) Take 1 g of the acidic porous polymer material synthesized above and immerse it in degassed ethylene glycol / glycerol...

Embodiment 2

[0137] This embodiment is different from embodiment 1 in that:

[0138] Add 0.16g of N,N'-methylenebisacrylamide in step (1).

[0139] It is measured that the contact angle between the material and water is 131°, and the acid content is 0.21mmol / g.

[0140] All the other reaction conditions are the same as in Example 1.

[0141] According to the test and calculation based on the formulas (I) and (II), the conversion rate of fructose is >99%, and the yield of 2,5-dimethylfuran reaches 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com