Snus preparation method

A technology for snus and tobacco powder, which is applied in the directions of preparing tobacco, chemical instruments and methods, tobacco, etc., can solve the problems of limiting the raw material space of smokeless tobacco products, being difficult to meet the requirements for use, strong spicy taste, etc., and achieving a rich taste. , the preparation method is fine, the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The idea, specific structure and technical effects of the present invention will be further described below in conjunction with the accompanying drawings, so as to fully understand the purpose, features and effects of the present invention.

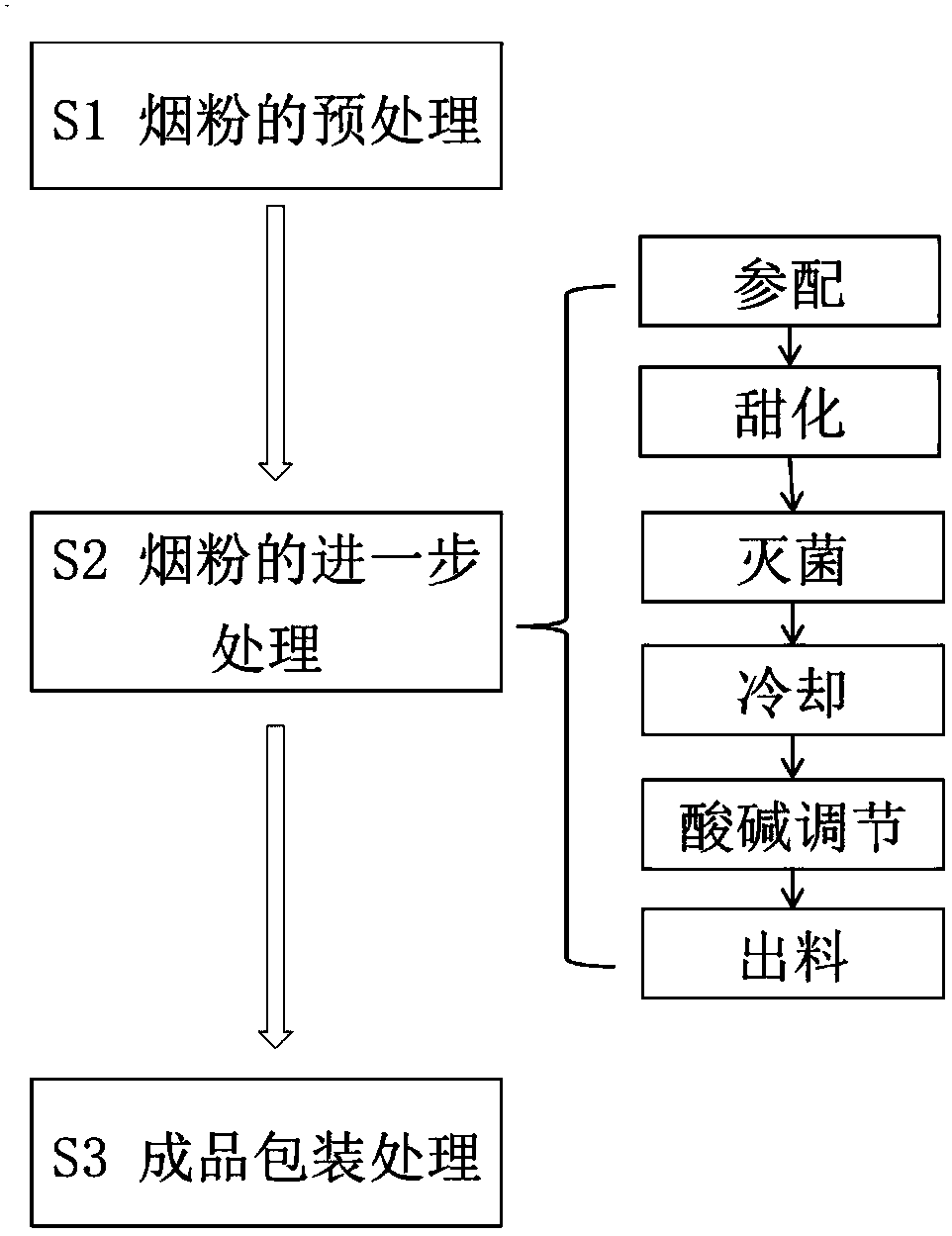

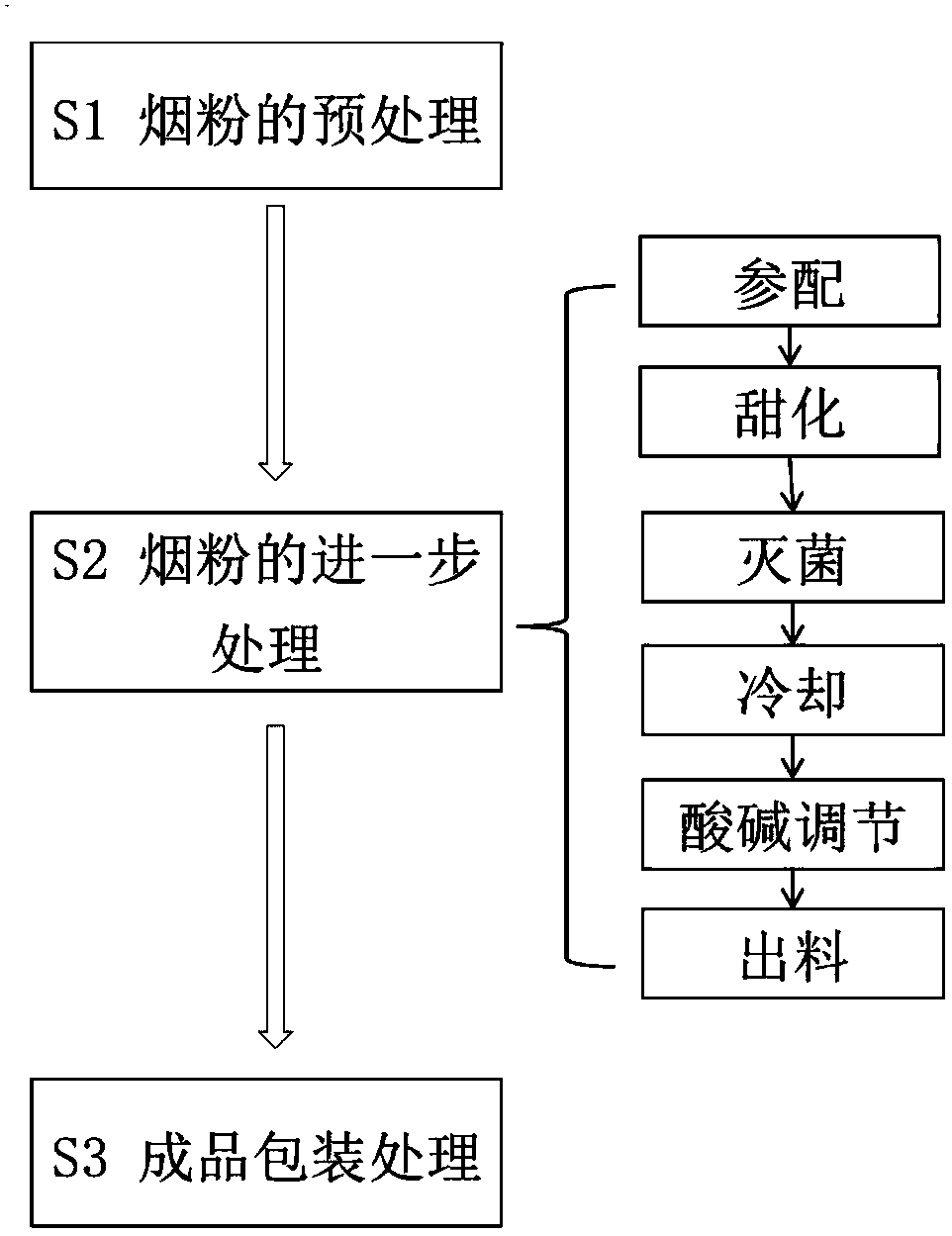

[0024] Such as figure 1 As shown, the preparation method of snus in this embodiment comprises the following steps:

[0025] Step 1, the pretreatment of tobacco powder includes the process of feeding by turning over the box, opening the cigarette block, vibrating and opening, automatically weighing and feeding the process, and pneumatically feeding the process.

[0026] Among them, the process of feeding the box and opening the cigarette block specifically includes:

[0027] Manual cigarette packet opening process: The incoming raw materials are mostly cigarette sheets packed in C-48 specification cartons, which are dense cigarette blocks after hydraulic packing, which need to be manually loosened and taken out first, and packed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com