SOI device structure

A device and high-voltage device technology, applied in the field of SOI device structure, can solve the problems of ignoring the improvement of the field oxide layer and the influence of heat dissipation cannot be ignored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

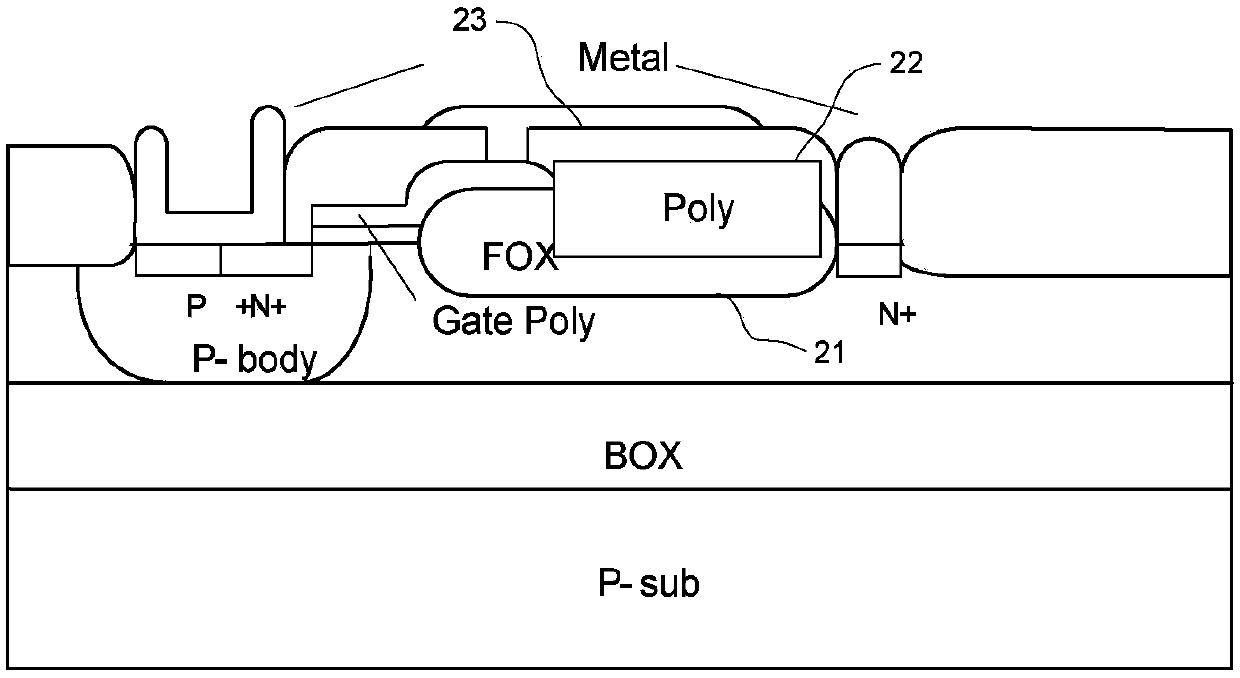

[0015] figure 2 It is a schematic diagram of the SOI-LDMOS structure in the first embodiment of the present invention. This structure changes the material of the field oxide layer 21 into an undoped POLY material. After the field oxide layer grows, part of it is etched away, and POLY22 is deposited. An isolation oxide layer 23 is then deposited, and finally a metal electrode is deposited. Due to SiO 2 The thermal conductivity of Si is about 1 / 100, but the dielectric constant is 3 times that of Si, so this change can greatly reduce the thermal resistance of the field oxygen part, which is conducive to heat dissipation, while the thermal resistance of the field oxide layer and the buried layer The thermal resistance is equivalent to a parallel relationship, and the significantly lower thermal resistance of the field oxide layer will cause most of the heat to be lost from the field oxide layer, which can achieve the purpose of effective heat dissipation.

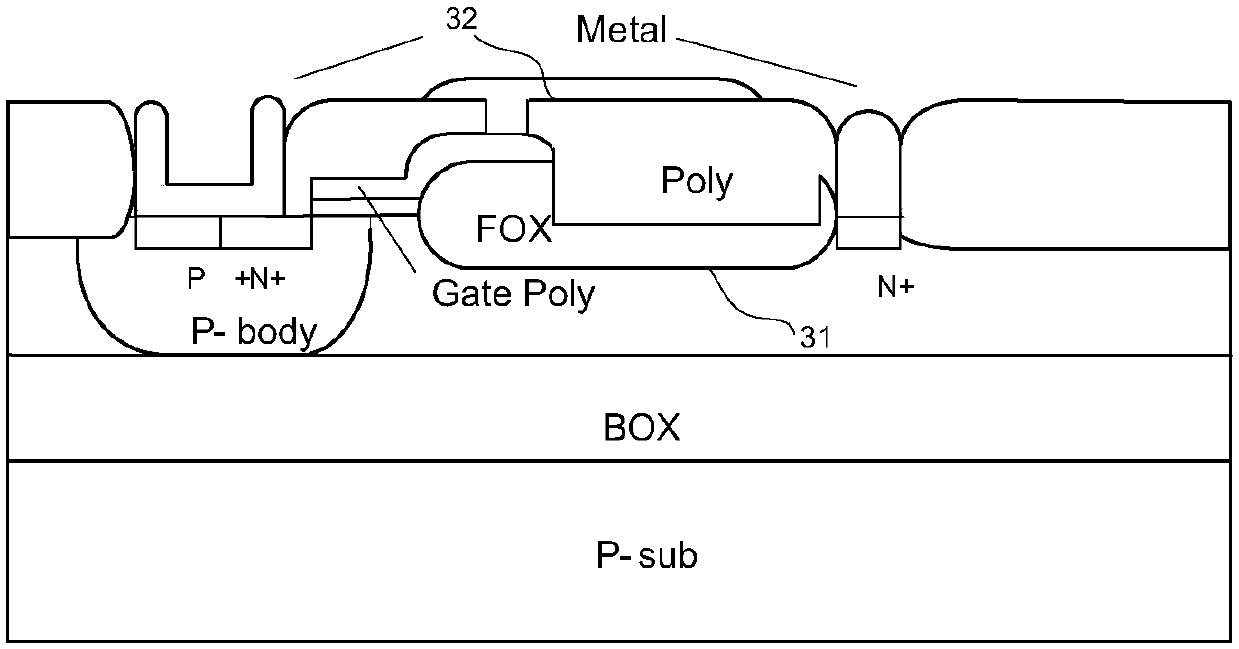

[0016] image 3 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com