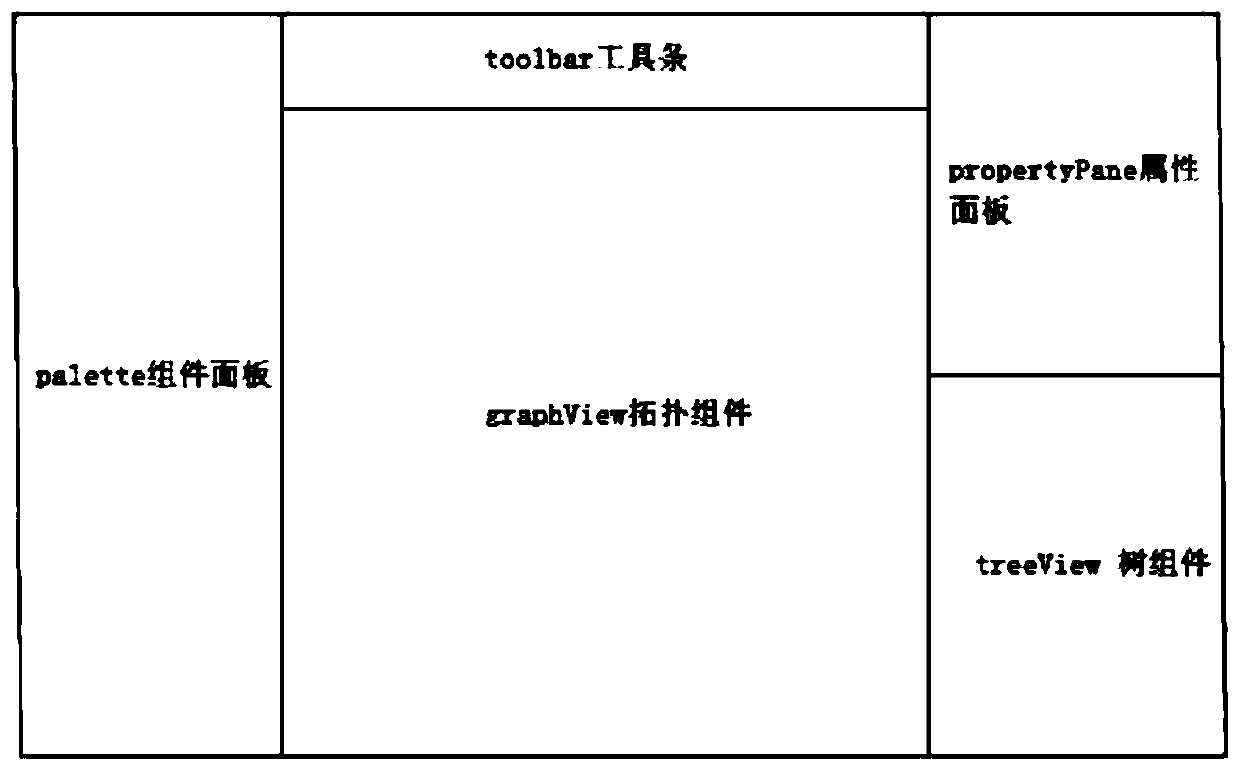

Web configuration method for industrial equipment

A technology of industrial equipment and industrial field equipment, which is applied in the field of Web configuration for industrial equipment, can solve the problems that the configuration software cannot be fully connected, the remote control ability is poor, and it cannot be clicked or dragged to avoid equipment The effect of communication heterogeneity problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] refer to figure 1 and figure 2 , a web configuration method for industrial equipment, specifically including the following steps:

[0040] S1. Build cloud data: cloud data includes configuration application server, file server and data server;

[0041] S2. Collect, store, knowledge mine and package industrial field equipment data with IoT technology;

[0042] S3. Operation and use: The cloud provides configuration applications to users through the network, and users remotely access industrial site data and configuration editors, and click, drag and drop devices, and layout them into configuration editors according to needs or actual conditions. Form a simulation screen that is consistent with the industrial site, and connect the dynamic data source that matches the industrial site equipment for the simulation screen, and link the data source with the simulation interface to finally form a data-driven animation interface;

[0043] Wherein S3 specifically includes the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com