Intensity check method of vehicle bonding structure in full temperature field environment

A technology with structural strength and full temperature, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., and can solve the problems that mechanical connection technology cannot fully meet the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Concrete embodiment of the present invention and process are as follows:

[0017] 1. Selection of adhesive and bonding substrate.

[0018] The adhesive selected in the experiment is a modified silane polyurethane adhesive ISR-7008 (produced by Bostik China Co., Ltd.), which is widely used in the bonding of cars, trucks and train windows. Parameters, as shown in Table 2.1. The operating temperature range provided in the technical manual is -40°C-90°C. Forms a permanent elastomer by reacting with water in the air. The bonding base material is 6005A aluminum alloy, which is widely used in automobile body structures.

[0019] Table 1 Select the mechanical parameters and properties of bonding materials

[0020]

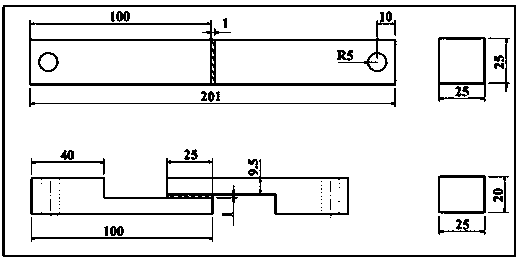

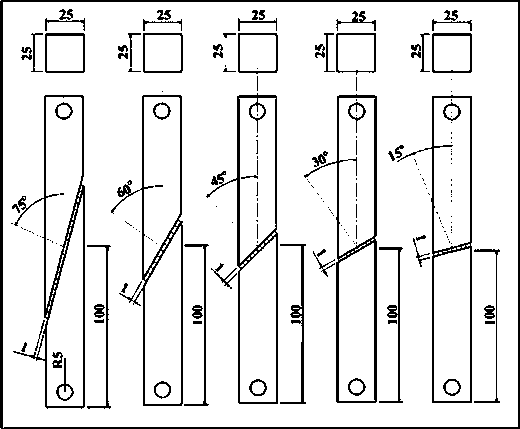

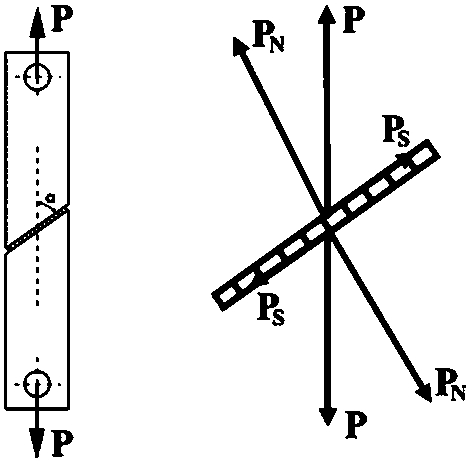

[0021] 2. Design and processing of bonded specimens and force analysis of bonded surfaces.

[0022] Butt joint and lap joint specimens are designed to study the mechanical properties of bonded joints under tensile stress state and shear stress state, respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com