Jet type stress-erosion corrosion test device

A technology of erosion corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, and the use of stable bending force to test the strength of materials, etc., can solve the problems of inability to complete stress-erosion corrosion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

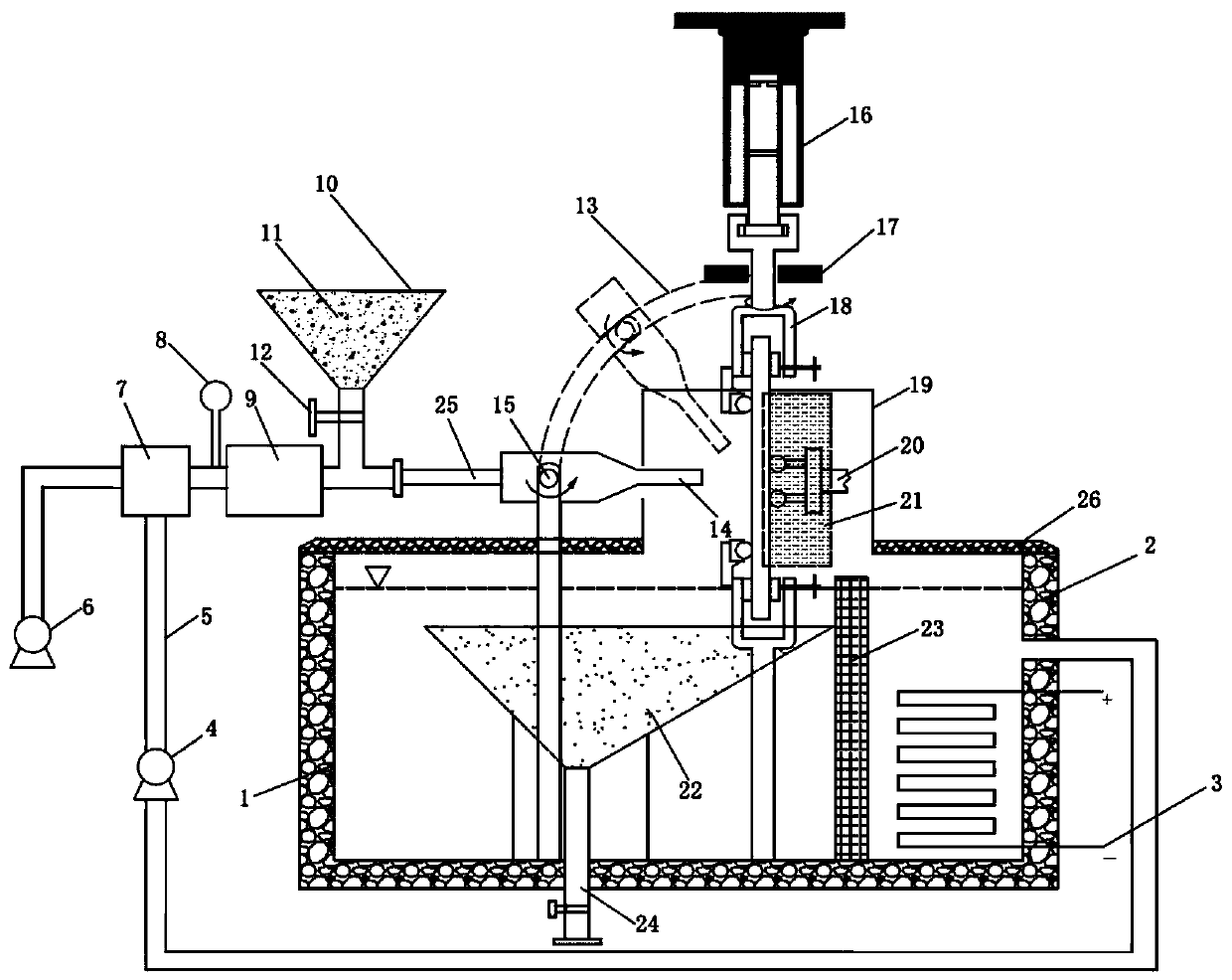

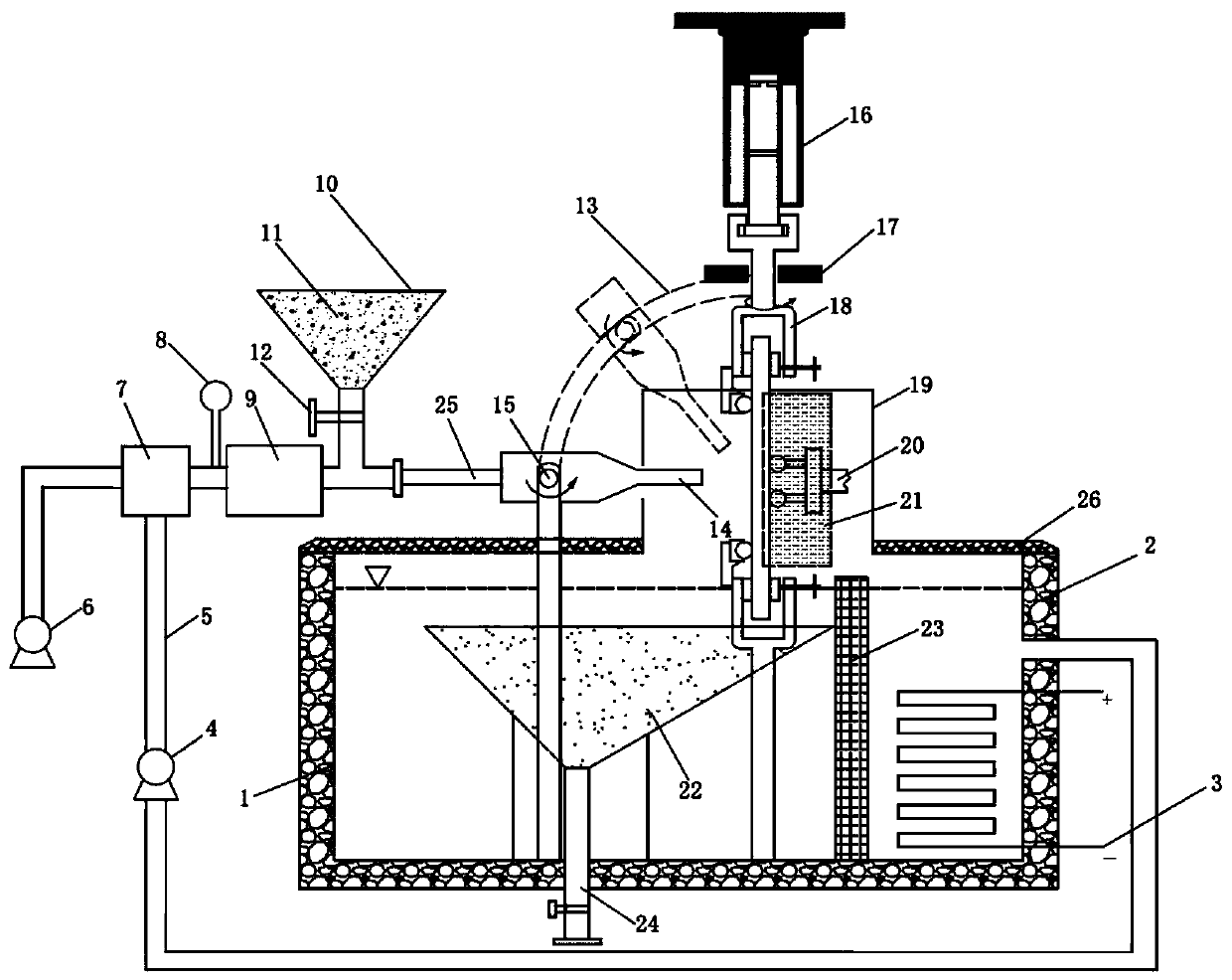

[0012] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

[0013] Such as figure 1 As shown, the device includes a liquid storage tank, a circulation system, a specimen installation and a stress loading mechanism. The liquid storage tank 1 is equipped with a box body insulation layer 2, a liquid storage tank upper cover 26 and a heater 3, which can heat the test solution, and adjust the power of the heater 3 through the reading of the temperature sensor 8 at the front of the nozzle; the circulation system 5 includes a water pump 4. The air pump 6 and the gas-liquid mixer 7 can use liquid, gas or gas-liquid mixture as the transmission medium, and control the speed of the water pump 4 and air pump 6 according to the reading of the electronic flowmeter 9 at the front of the nozzle to control the injection speed; the front of the nozzle is provided with a sand storage box 10. The particle content of the medium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com