Cooling tower sprinkler

A tower sprinkler and water basin technology, which is applied in the field of cooling tower sprinklers, can solve the problems of rushing to the water sowing basin, no sprinkler configuration, and no sprinkler relief, etc., to achieve reduced vibration, good production process, and small cost The effect of water noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

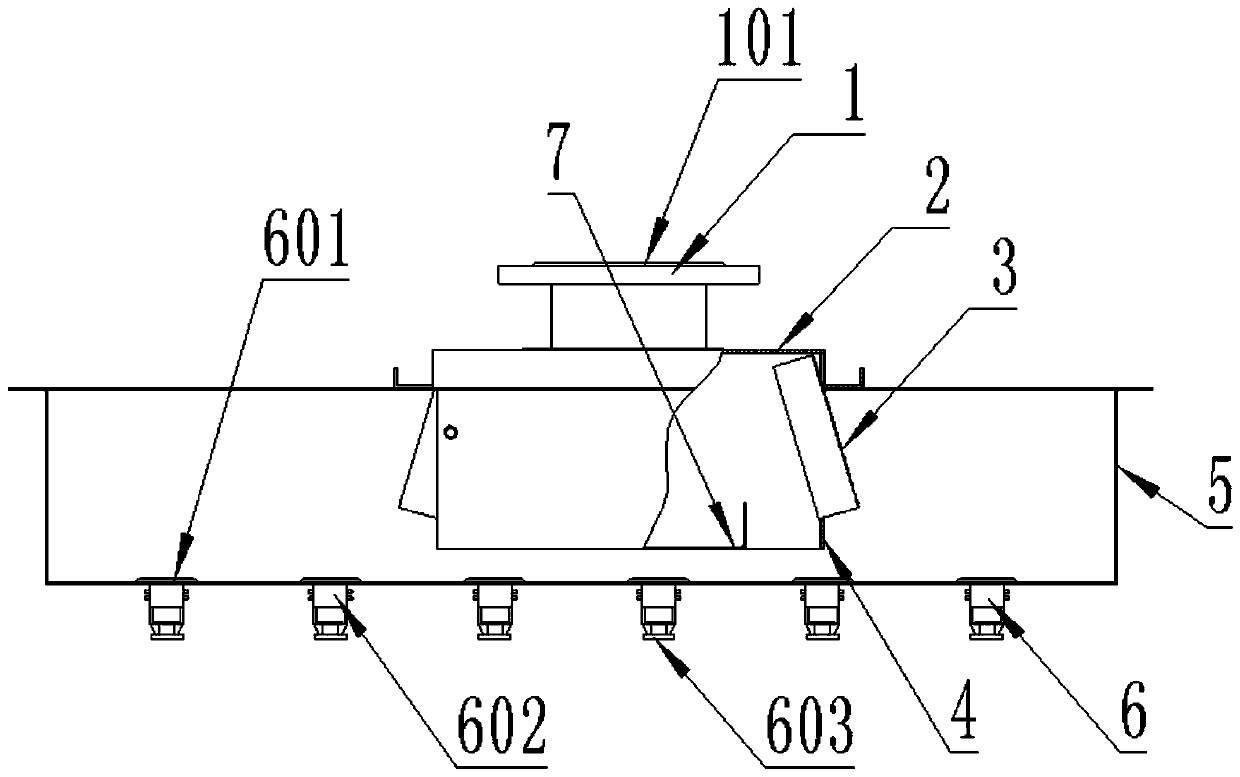

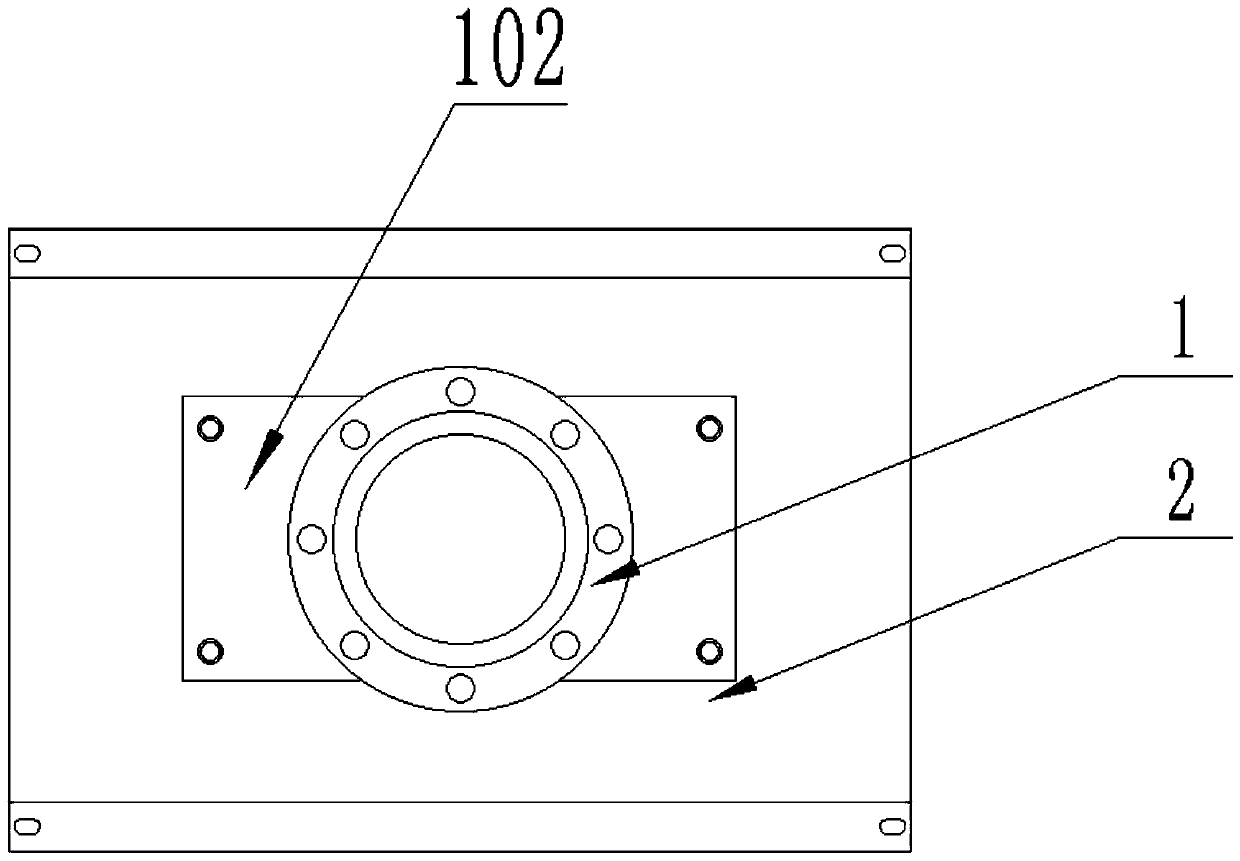

[0021] After the sprinkler is assembled, the flange surface of the water inlet pipe 1 is fixedly connected with the outlet flange of the tower body by bolts, and the centering connection with the outlet pipe of the tower body is realized through the centering boss 101, thereby avoiding the There are problems such as water flow additional impact, water seepage and so on. When working, the circulating water of the cooling tower enters through the water inlet pipe 1, impacts on the impact plate 7, and then falls into the watering basin 5 after splashing. This structure reduces the direct reconnection of the water flow to the bottom plate of the watering basin 5, thereby reducing the Noise, prolong service life; during normal operation, the liquid level in the watering basin 5 is higher than the lower plane of the anti-support plate 3, so that the pressure is maintained in the inner space of the two anti-support plates 3 placed obliquely, so that the cooling water passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com