Self-cooling type cooling water pump for engine

A technology for cooling water pumps and engines, which is applied in the cooling of engines, engine components, machines/engines, etc., can solve the problems of limiting the continuous working time and speed of the water pump, the influence of the service life of the water pump, and the use of the water pump, so as to improve the energy utilization rate. , the effect of improving cooling efficiency and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

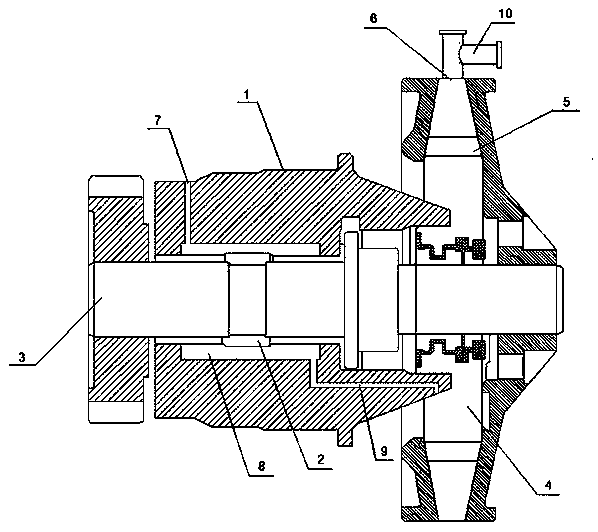

[0022] Embodiment 1: This embodiment provides a self-cooling engine cooling water pump, including a pump housing 1, the right end of the pump housing 1 is provided with an impeller 5 cavity 4, a bearing 2 is installed in the pump housing 1, and the bearing 2 rotates The pump shaft 3 is installed, the right end of the pump shaft 3 is equipped with an impeller 5, the impeller 5 is located in the chamber 4 of the impeller 5, the left end of the pump shaft 3 extends outside the pump casing 1 and is connected with the gear, which is connected with the engine for transmission and works At this time, the engine drives the pump shaft 3 to rotate through the gear, thereby driving the impeller 5 to rotate in the cavity 4 of the impeller 5 .

[0023] A liquid inlet 6 and a liquid outlet 7 are opened on the pump casing 1, and a cooling chamber 8 is opened in the pump casing 1, see figure 1 , the cooling chamber 8 is a hollow cylinder and covers the outside of the bearing 2. The length of ...

Embodiment 2

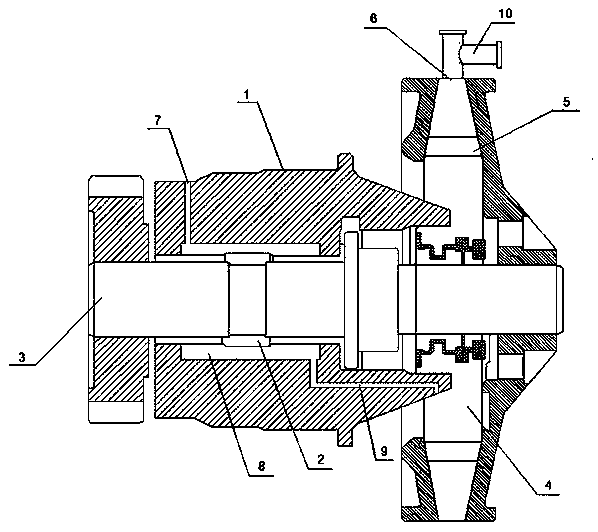

[0027] Embodiment 2: This embodiment provides a cooling water pump for a self-cooling engine. The difference from Embodiment 1 is that the cooling chamber 8 in this embodiment is a spiral pipe wound outside the bearing 2. See figure 2 , the spiral pipe completely covers the outer surface of the bearing 2, the coolant in the cavity 4 of the impeller 5 enters from one end of the spiral pipe, then flows along the pipe and is transported to the liquid outlet 7 on the pump casing 1 place, so that the spiral pipe is always filled with coolant, which ensures the coverage area of the coolant and has higher heat absorption efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com