Section steel-UHPC composite board and bridge deck

A technology of combining slabs and bridge decks, used in bridges, bridge parts, bridge construction, etc., can solve problems such as bridge deck cracking and reducing the dead weight of main beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

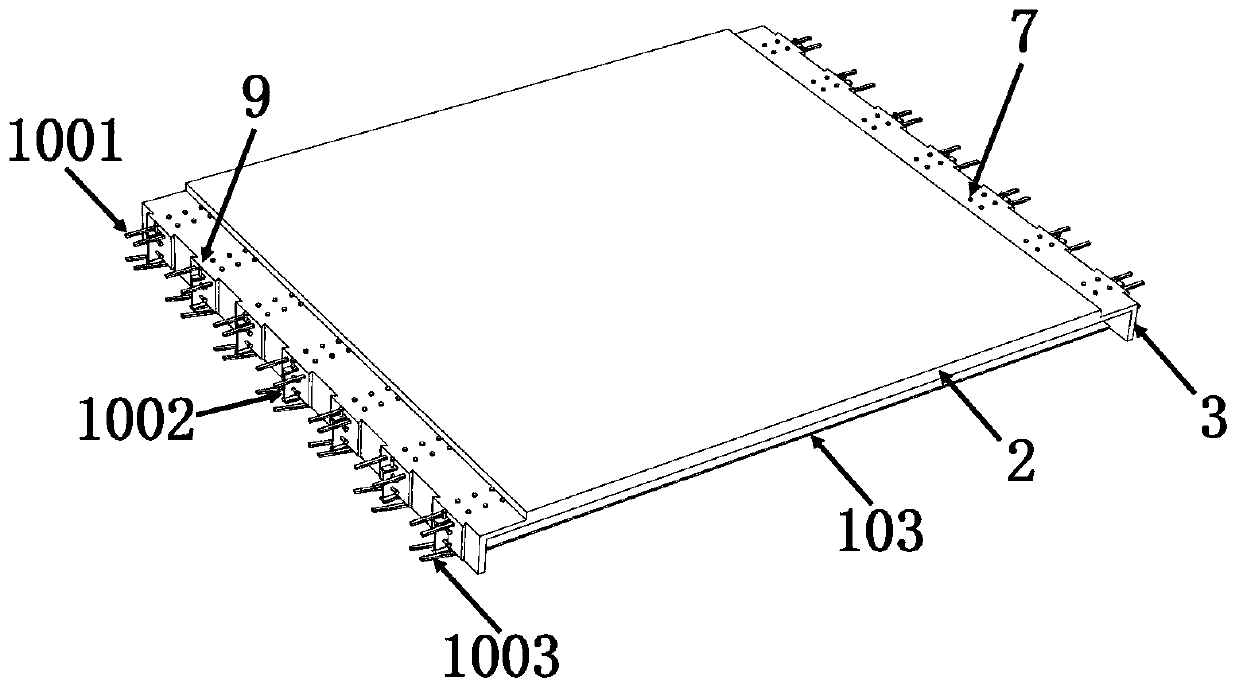

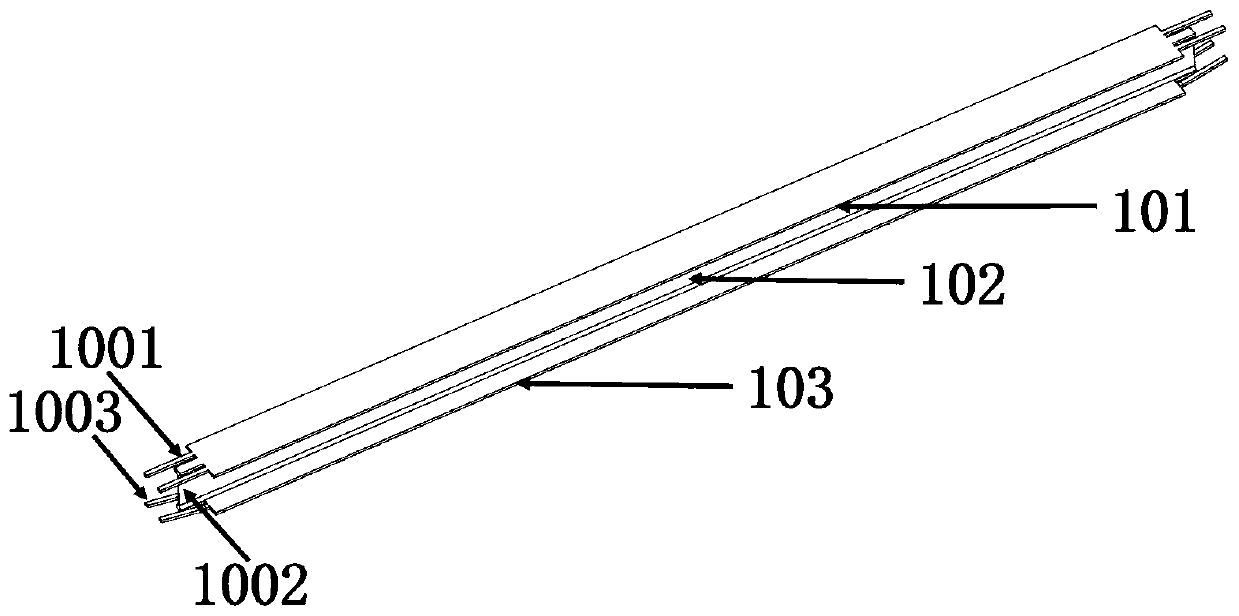

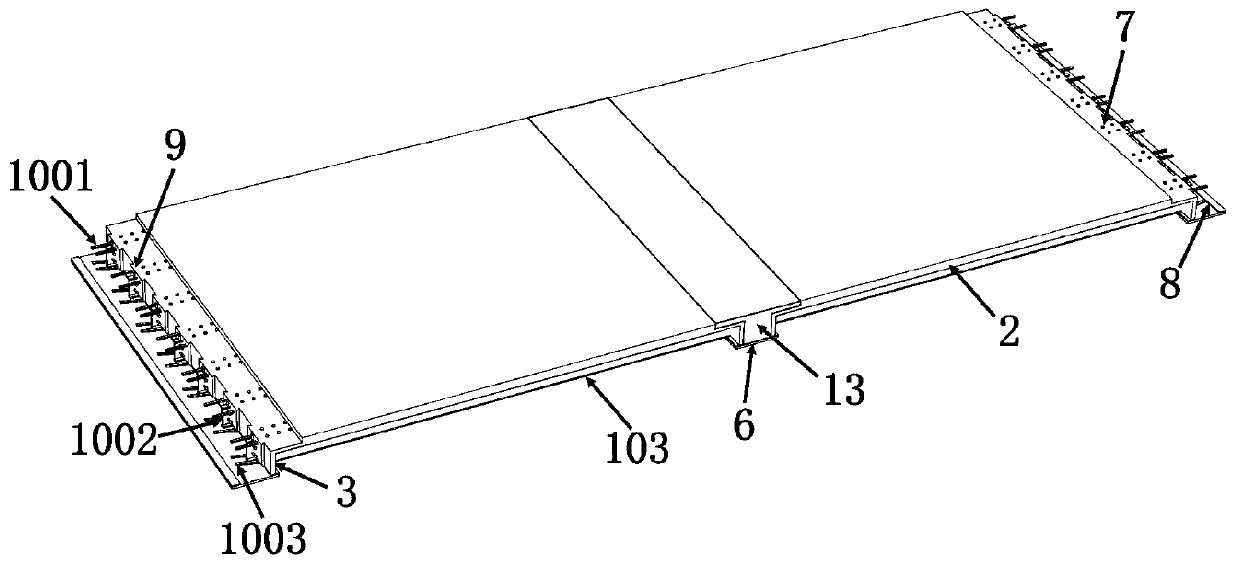

[0071] Such as figure 1 As shown, the steel-UHPC composite plate of this embodiment includes a plurality of steel beams 1 and UHPC boards 2 fixed on the steel beams 1, the steel beams 1 are arranged in parallel along the longitudinal bridge direction, and the steel beams 1 include upper flanges 101, the web 102 and the lower flange 103 (type steel 1 such as I-beam, channel steel, U-shaped steel, etc.), the UHPC plate 2 is fixed on the upper flange 101, the upper flange 101, the web 102 and the lower flange The end of the edge 103 is provided with an upper flange overhang 1001 , a web overhang 1002 and a lower flange overhang 1003 extending outward.

[0072] In this embodiment, the upper flange overhanging section 1001 is a plurality of long straight strips arranged at intervals, and the lower flange overhanging section 1003 is a plurality of intervals arranged and inclined upward (the inclination angle is between 10° and 60°). Can) long straight strips (the lower flange overh...

Embodiment 2

[0094] Such as Figure 20 As shown, the profile steel-UHPC composite plate of this embodiment is different from that of Example 1 in that there is no lower flange 103 in the profile steel 1 (the type of profile steel 1 can be angle steel, T-shaped steel, bulb flat steel, etc.).

[0095] In this embodiment, the schematic diagram of the steel structure is as follows Figure 21 shown.

[0096] Such as Figure 22 As shown, the bridge deck in this embodiment is mainly composed of a plurality of above-mentioned steel-UHPC composite plates connected longitudinally and bridgewise, and adjacent bridge decks are connected by cast-in-place connecting parts 13 .

[0097] In this embodiment, the arrangement of the shaped steel 1 in the two adjacent shaped steel-UHPC composite panels can be any of the following structures, such as Figure 23 As shown, the section steels 1 in the adjacent section steel-UHPC composite panels are arranged in one-to-one correspondence. Such as Figure 24 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com