String structure, string beam and building

A technology of building and string beams, applied in the field of tension string structures, can solve problems such as failure and large tension, and achieve the effect of improving support capacity and span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

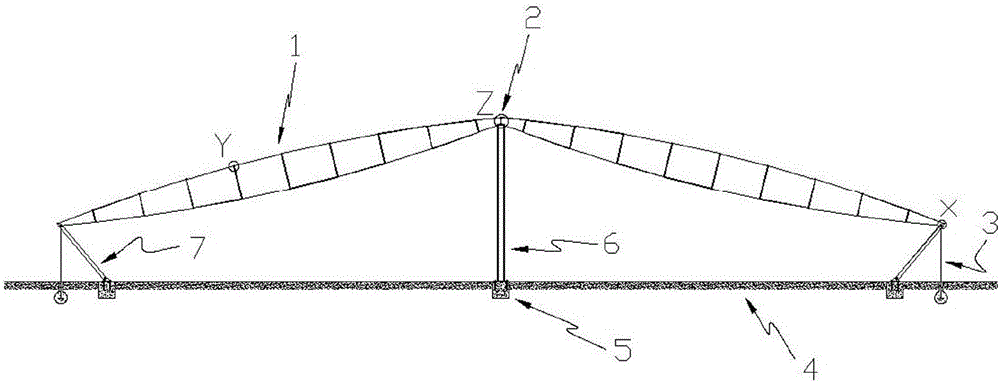

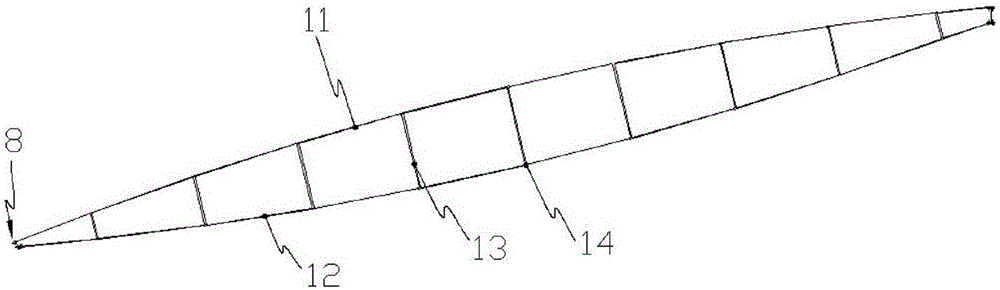

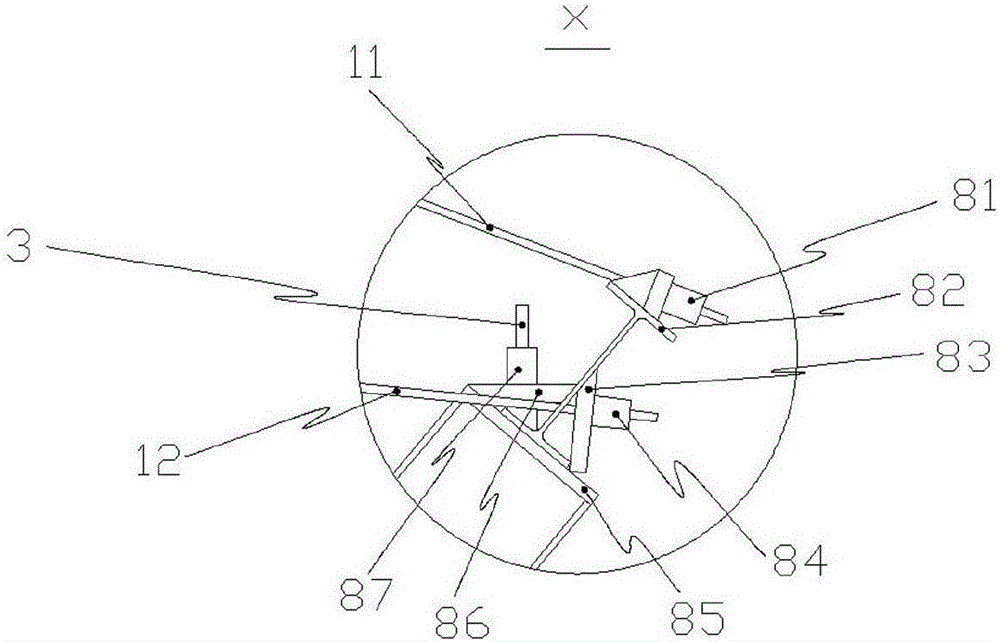

[0061] In the present invention, the basic construction unit is the tension string structure, which is vertically arranged, so that the vertical plane where it is located is a longitudinal plane, and then, in the spanned space, here it is a longitudinal span.

[0062] Horizontally, it is constrained by the number of string beams 1, however, the number of string beams 1 is not affected by the span.

[0063] Conventionally, the current string structure used by the string beam, such as the string beam or similar string structure cited in the background technology section, is essentially a rigid beam part, or has a "rigid part" in a semi-rigid structure. ".

[0064] It should be understood that for a flexible member, such as a cable commonly used in construction, when it is stretched horizontally, taking the line connecting the tension points at both ends as a reference, affected by its own weight, the closer it is to the middle, the more drooping it will be. In plane geometry, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com