PVC easy-to-process opaque high-impact MBS and preparation method thereof

A high-impact, easy-to-process technology, applied in the field of PVC easy-to-process opaque high-impact MBS and its preparation, can solve the problems of poor processing fluidity and low impact strength, and achieve the goal of increasing impact strength and improving impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

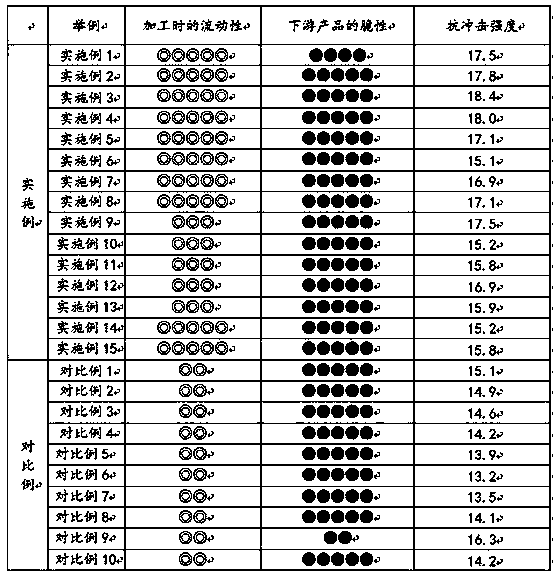

Examples

Embodiment 1

[0030] (1) Add the formula amount of water, emulsifier, inorganic salt, molecular weight regulator, styrene monomer and butyl acrylate monomer in a ratio of 95 / 5, crosslinking agent, initiator to the reactor, and then close Reactor cover, heat up to the reaction temperature to react until the reaction is complete; or use a reactor alone to react, take the reacted emulsion of the formula amount and add it to the MBS reactor as the core layer seed, and the core layer accounts for 10%;

[0031] (2) Add the prescribed amount of water, emulsifier, inorganic salt solution, 10% core layer seeds, molecular weight modifier, crosslinking agent, and initiator into the autoclave, then close the lid of the autoclave and tighten the bolts, Then put butadiene and styrene into the reactor, wherein the ratio of butadiene and styrene is 95 / 5, and the middle layer accounts for 75%;

[0032] (3) Heat up to 70°C and react until the reaction is complete;

[0033] (4) Then add emulsifier, the mixtu...

Embodiment 2

[0036] In the step (1) of Example 1, the ratio of styrene monomer and butyl acrylate monomer in the core layer was changed to 75 / 25, and the rest were the same as in Example 1.

Embodiment 3

[0038] In the step (1) of Example 1, the ratio of styrene monomer and butyl acrylate monomer in the core layer was changed to 50 / 50, and the rest were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com