Method for reducing nitrogen loss in municipal sludge composting process

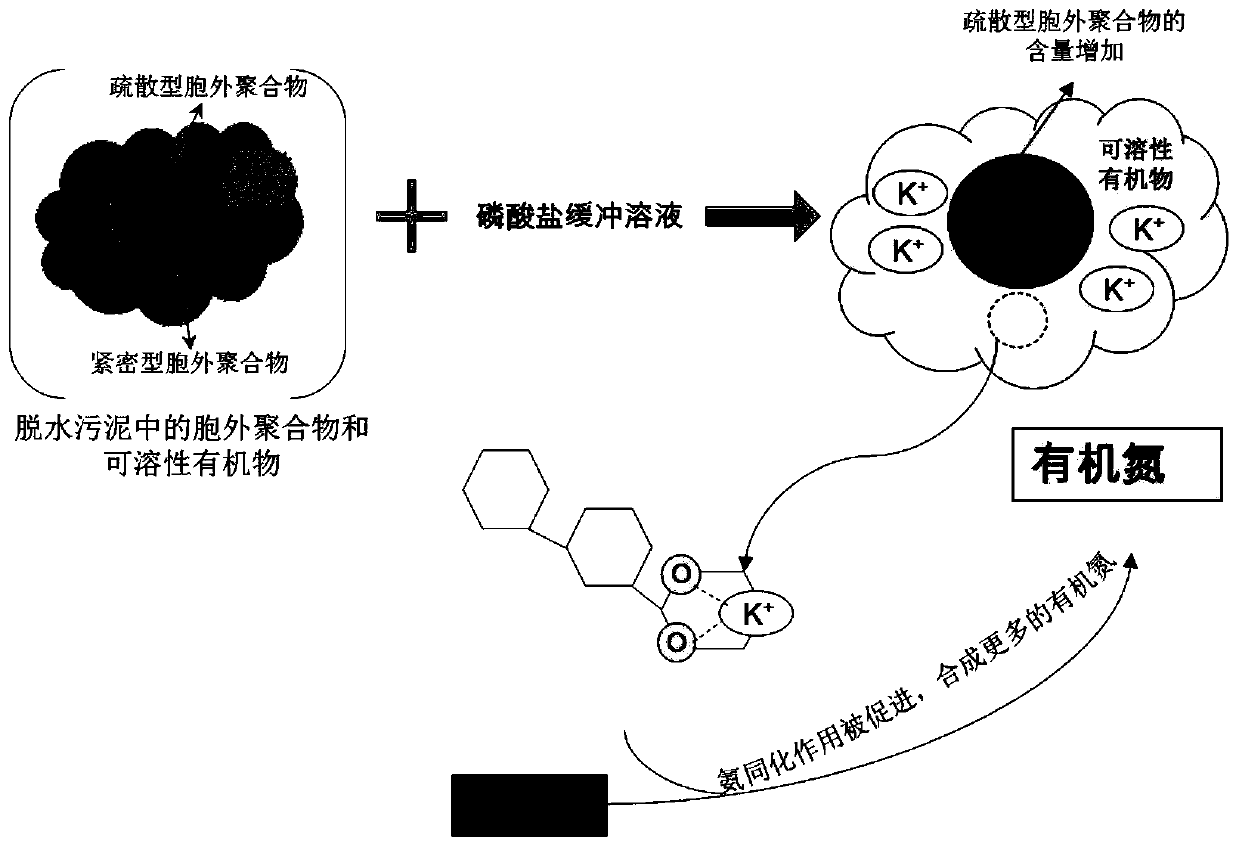

A municipal sludge and composting technology, applied in the field of environmental engineering, can solve the problems of high environmental requirements for ion concentration generation and difficult operation, and achieve the effects of reducing the escape of ammonia gas, strong operability, and enhanced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Raw materials for composting: 2kg of dewatered sludge (water content 80%, dry weight of dewatered sludge 0.4kg) from a city sewage treatment, 0.65kg of sawdust as conditioner, phosphate buffer solution containing 0.1mol potassium monohydrogen phosphate and 0.1 200 ml of a solution of potassium dihydrogen phosphate with a pH of 6.8.

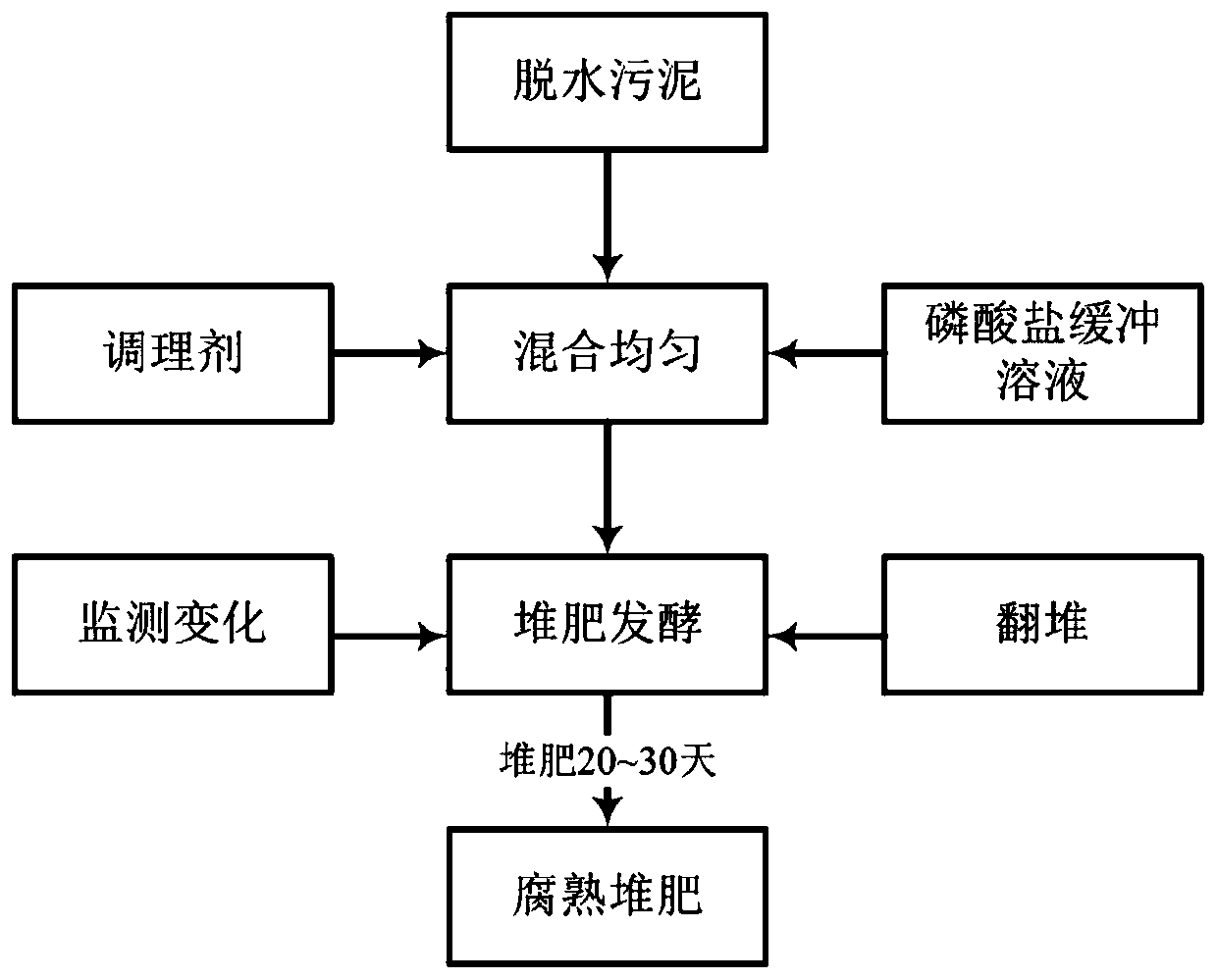

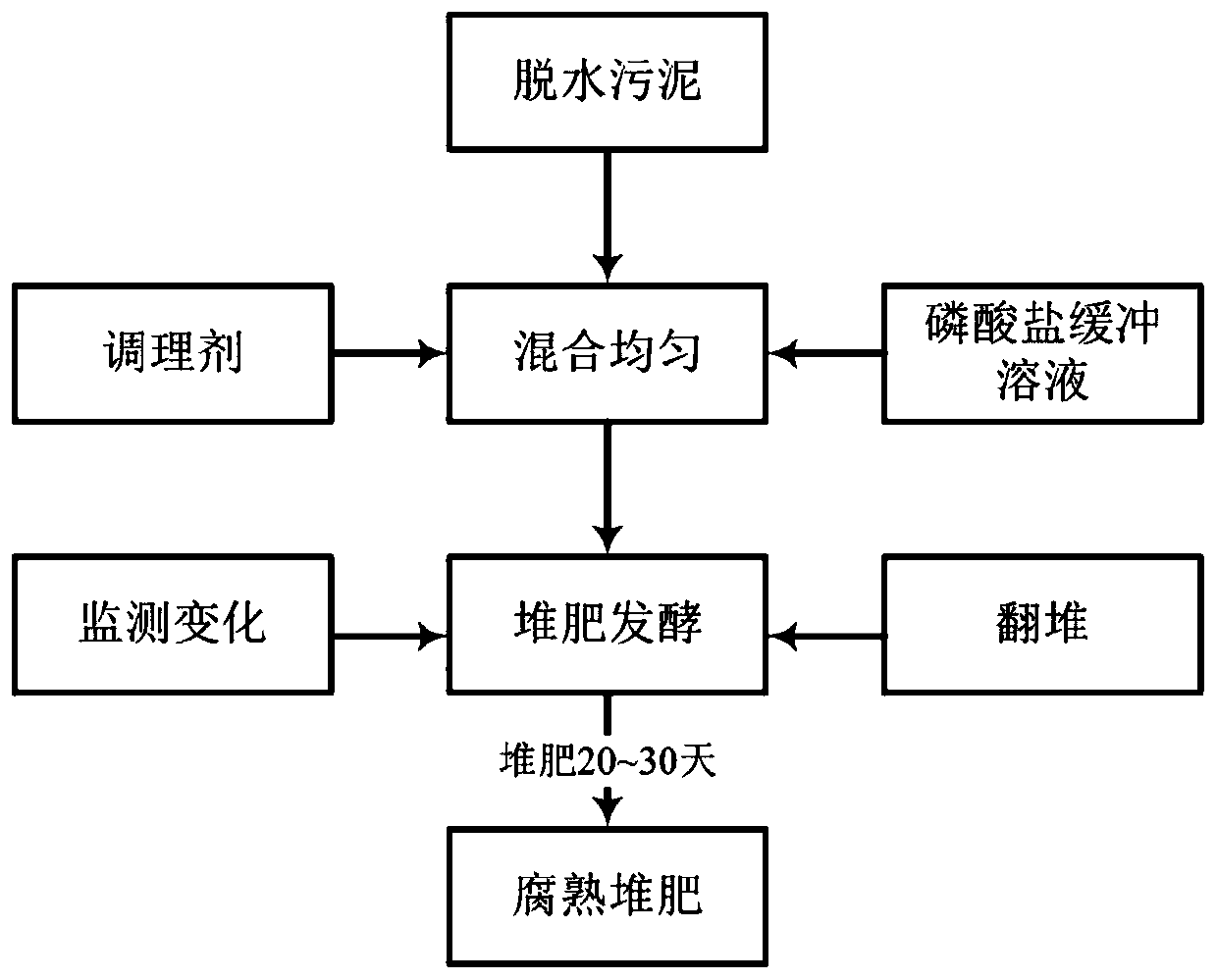

[0033] The above raw materials are attached figure 1 The process flow shown is mixed, and after mixing, the compost with a moisture content of 65% is put into the tank for forced ventilation static composting, and the ventilation rate is 0.2L / min / kg dry weight of the material. Compost for 30 days and turn over every 6 days.

[0034] During composting, samples were taken every 6 days to measure the moisture content, ammonium nitrogen, nitrate nitrogen, total nitrogen and organic matter of the compost. The experimental results showed that when no phosphate buffer was added, the nitrogen loss of sludge compost was 65.3%, and the nitrogen lo...

Embodiment 2

[0036] Composting raw materials: 2kg of dewatered sludge (water content 85%, dry weight of dewatered sludge 0.3kg) from a city sewage treatment, 1.3kg of straw as a conditioner, phosphate buffer solution containing 0.018mol sodium monohydrogen phosphate and 0.132 mol of sodium dihydrogen phosphate pH 6.0 solution 200 ml.

[0037] The above raw materials are attached figure 1 The process flow shown is mixed, and after mixing, the compost with a moisture content of 55% is put into the tank for forced ventilation static composting, and the ventilation rate is 0.4L / min / kg dry weight of the material. Compost for 20 days and turn over every 4 days.

[0038] During the composting period, samples were taken every 4 days to measure the moisture content, ammonium nitrogen, nitrate nitrogen, total nitrogen and organic matter of the compost. The experimental results showed that when no phosphate buffer was added, the nitrogen loss of sludge compost was 60.3%, and the nitrogen loss of add...

Embodiment 3

[0040] Compost raw materials: 2kg of dewatered sludge (water content 82.0%, dry weight of dewatered sludge 0.36kg) from a city sewage treatment, conditioner is 0.8kg of sawdust, phosphate buffer solution contains 0.114mol sodium monohydrogen phosphate and 0.006 200 ml of a solution of potassium dihydrogen phosphate with a pH of 8.0.

[0041] The above raw materials are attached figure 1 The process flow shown is mixed, and after mixing, the compost with a moisture content of 62.5% is put into the tank for forced ventilation static composting, and the ventilation rate is 0.3L / min / kg dry weight of the material. Compost for 25 days and turn over every 5 days.

[0042] During the composting period, samples were taken every 5 days to measure the moisture content, ammonium nitrogen, nitrate nitrogen, total nitrogen and organic matter of the compost. The experimental results showed that when no phosphate buffer was added, the nitrogen loss of sludge compost was 64.3%, and the nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com