Preparation method of antibacterial gel with polyethyleneimine as gel matrix

A polyethylenimine and gel matrix technology, applied in bandages, medical science, etc., can solve the problems of high difficulty in process control, complicated hydrogel preparation process, poor antibacterial effect of hydrogel, etc., and achieve good inhibitory effect, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

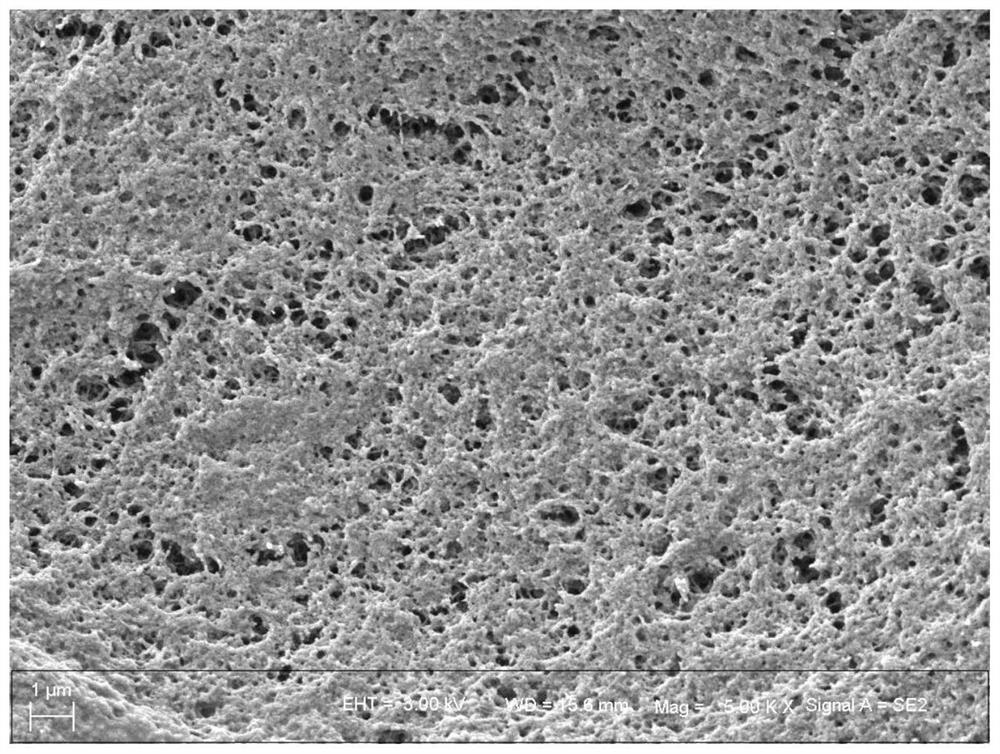

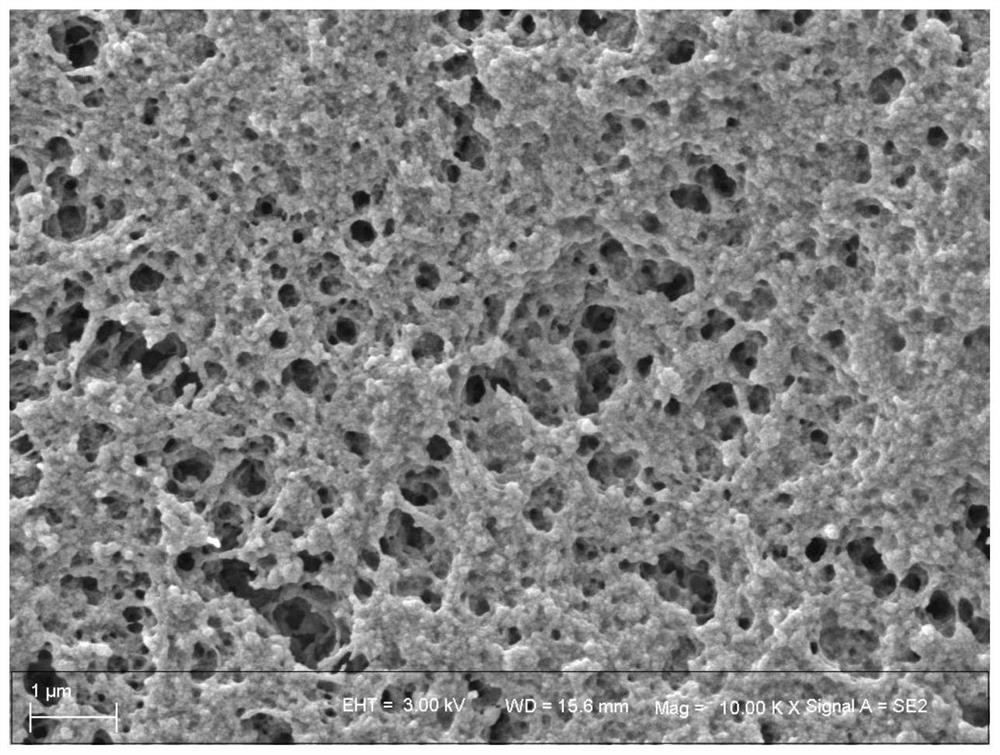

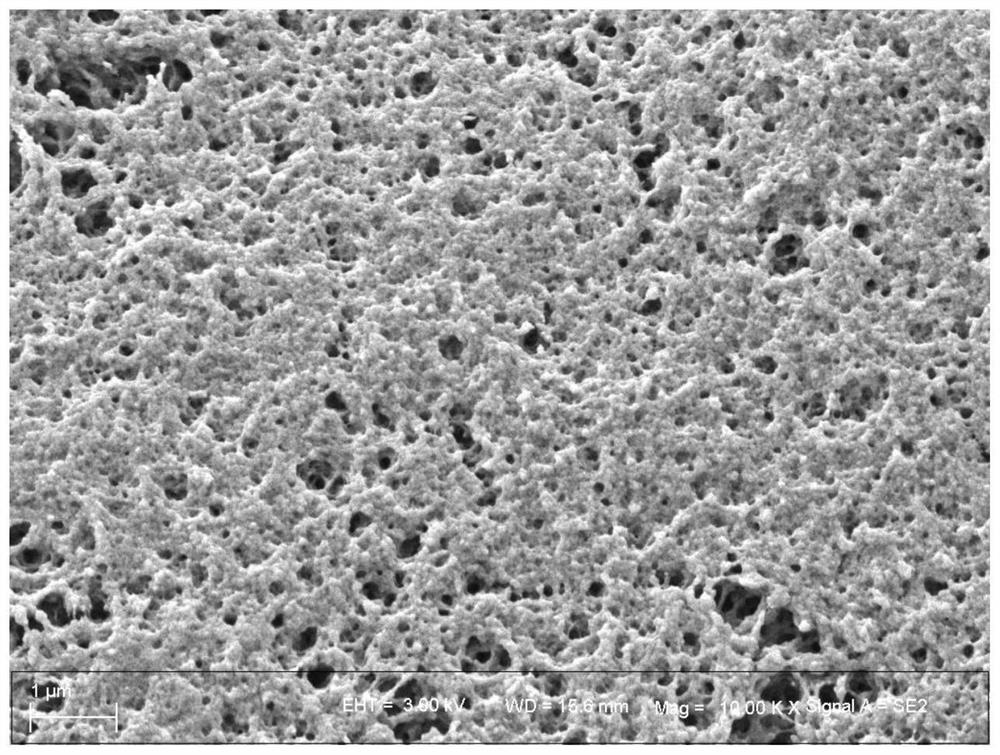

Image

Examples

Embodiment 1

[0034] A kind of preparation method that takes polyethyleneimine as the antibacterial gel of gel base, comprises the following steps:

[0035] Step 1. Add polyethyleneimine to 10mmol / L Tris-Hcl buffer to prepare a polyethyleneimine solution with a concentration of 64mg / mL; add catechol to 10mmol / L Tris-Hcl buffer In, the preparation concentration is the catechol solution of 26.4mg / mL;

[0036] Step 2, 5g polyethyleneimine solution, 5g catechol solution, 1g chitosan, 0.1g carbomer, 0.1g hyaluronic acid, 0.1g sodium benzoate, 0.05g konjac glucomannan and 0.1g H with a mass fraction of 30% 2 o 2 After mixing, stir at a speed of 1500r / min for 10min, and then pressurize and ultrasonicate for 60min to obtain an antibacterial gel; the pressure of the pressurized ultrasonic is 0.5MPa; the ultrasonic frequency is 75KHz, and the ultrasonic power is 300W;

[0037] After testing, the antimicrobial gel obtained in this example has a bacteriostatic rate of 97.1% and 97.4% for Escherichia...

Embodiment 2

[0039] A kind of preparation method that takes polyethyleneimine as the antibacterial gel of gel base, comprises the following steps:

[0040] Step 1. Add polyethyleneimine to 10mmol / L Tris-Hcl buffer to prepare a polyethyleneimine solution with a concentration of 64mg / mL; add catechol to 10mmol / L Tris-Hcl buffer In, the preparation concentration is the catechol solution of 26.4mg / mL;

[0041] Step 2, with 6g polyethyleneimine solution, 6g catechol solution, 1.5g chitosan, 0.2g carbomer, 0.2g hyaluronic acid, 0.2g sodium benzoate, 0.1g konjac glucomannan and 0.2 g with a mass fraction of 30% H 2 o 2 After mixing, stir at a speed of 2000r / min for 10min, and then pressurize and ultrasonicate for 45min to obtain an antibacterial gel; the pressure of the pressurized ultrasonic is 0.6MPa; the ultrasonic frequency is 75KHz, and the ultrasonic power is 300W;

[0042] After testing, the antibacterial rates of the antibacterial gel obtained in this example against Escherichia coli a...

Embodiment 3

[0044] A kind of preparation method that takes polyethyleneimine as the antibacterial gel of gel base, comprises the following steps:

[0045] Step 1. Add polyethyleneimine to 10mmol / L Tris-Hcl buffer to prepare a polyethyleneimine solution with a concentration of 64mg / mL; add catechol to 10mmol / L Tris-Hcl buffer In, the preparation concentration is the catechol solution of 26.4mg / mL;

[0046]Step 2, 8g polyethyleneimine solution, 7g catechol solution, 2g chitosan, 0.3g carbomer, 0.2g hyaluronic acid, 0.2g sodium benzoate, 0.1g konjac glucomannan and 0.1g H with a mass fraction of 30% 2 o 2 After mixing, stir at a speed of 2000r / min for 10min, and then pressurize and ultrasonicate for 45min to obtain an antibacterial gel; the pressure of the pressurized ultrasonic is 0.6MPa; the ultrasonic frequency is 75KHz, and the ultrasonic power is 300W;

[0047] After testing, the antibacterial rates of the antibacterial gel obtained in this example to Escherichia coli and Staphylococ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com