Clay cement-aggregate mixed grouting material and preparation method thereof

A technology of grouting material and mixed slurry, which is applied in the field of grouting reinforcement for mine water hazard control, can solve the problems of reduced strength, poor durability of gel, and easy pollution, etc., and achieves improved controllability, high plastic strength, and is not easy to Precipitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

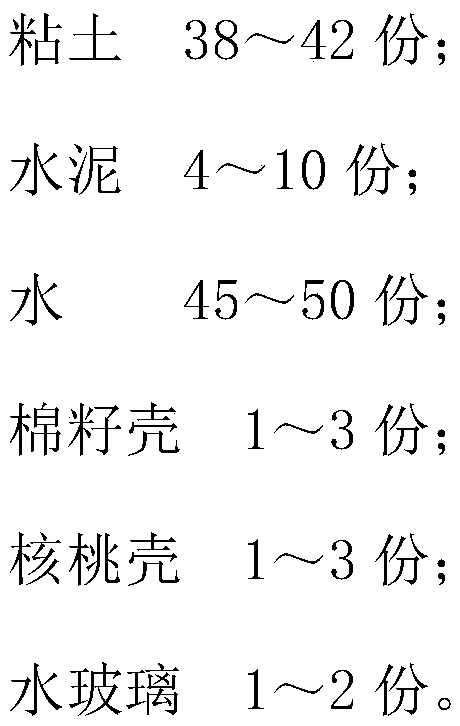

[0042] A clay cement-aggregate mixed grouting material, by mass, comprising:

[0043]

[0044]

[0045] Further, the cement is 325 ordinary portland cement.

[0046] Further, the clay is kaolin clay.

[0047] Furthermore, the clay has a plasticity index of 22.

[0048] Furthermore, the mineral content in the clay is >40%, and the organic matter content is <2%.

[0049] Furthermore, the particle size distribution of clay is:

[0050] 0.05 ~ 1mm powder grade 35%;

[0051] 0.005~0.05mm powder grade accounts for 50%;

[0052] The particle size of the remaining particles is less than 0.005 mm.

[0053] Further, the Baume degree of the water glass is 30. Water glass can react with cement to make the cement particles in the slurry hydrate faster and act as an accelerator in the formation of the slurry structure.

[0054] Further, the diameter of the cottonseed shell is 5mm. Cottonseed husks are the shells left after the cottonseeds are separated by the sheller. After mi...

specific Embodiment 2

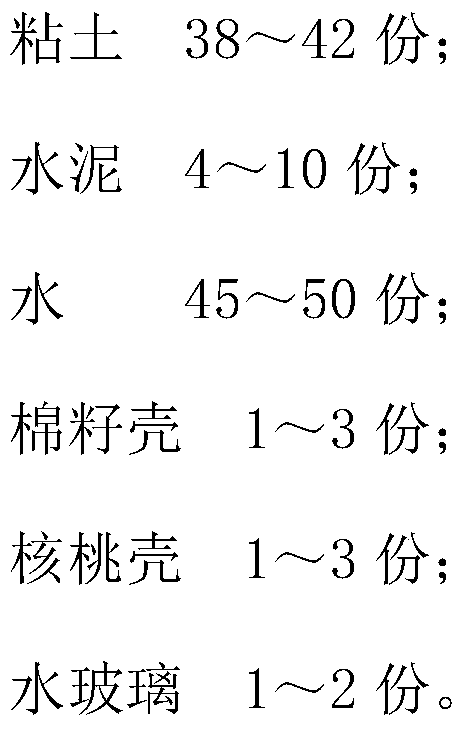

[0072] A clay cement-aggregate mixed grouting material, by mass, comprising:

[0073]

[0074] Further, the cement is 425 ordinary portland cement.

[0075] Further, the clay is kaolin clay.

[0076] Furthermore, the clay has a plasticity index of 10.

[0077] Furthermore, the mineral content in the clay is >40%, and the organic matter content is <2%.

[0078] Furthermore, the particle size distribution of clay is:

[0079] 0.05 ~ 1mm powder grade 10%;

[0080] 0.005~0.05mm powder grade accounts for 60%;

[0081] The particle size of the remaining particles is less than 0.005 mm.

[0082] Further, the Baume degree of the water glass is 20. Water glass can react with cement to make the cement particles in the slurry hydrate faster and act as an accelerator in the formation of the slurry structure.

[0083] Further, the diameter of the cottonseed shell is 3mm. Cottonseed husks are the shells left after the cottonseeds are separated by the sheller. After mixing with th...

specific Embodiment 3

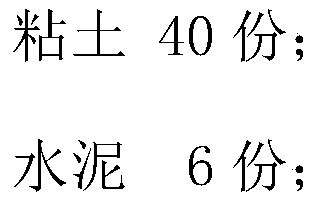

[0092] A clay cement-aggregate mixed grouting material, by mass, comprising:

[0093]

[0094] Further, the cement is 525 ordinary Portland cement.

[0095] Further, the clay is kaolin clay.

[0096] Furthermore, the clay has a plasticity index of 25.

[0097] Furthermore, the mineral content in the clay is >40%, and the organic matter content is <2%.

[0098] Furthermore, the particle size distribution of clay is:

[0099] 0.05 ~ 1mm powder grade accounts for 40%;

[0100] 0.005~0.05mm powder grade accounts for 30%;

[0101] The particle size of the remaining particles is less than 0.005 mm.

[0102] Further, the Baume degree of the water glass is 40. Water glass can react with cement to make the cement particles in the slurry hydrate faster and act as an accelerator in the formation of the slurry structure.

[0103] Further, the diameter of the cottonseed shell is 10mm. Cottonseed husks are the shells left after the cottonseeds are separated by the sheller. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com