Ring-integrated infusion bottle and manufacturing method thereof

A manufacturing method and technology of infusion bottles, which are applied in the field of plastic bottle manufacturing, can solve problems such as increased labor costs, increased quality risks, and increased production costs, and achieve the effects of reduced labor costs, no quality risks, and no need for heating and welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

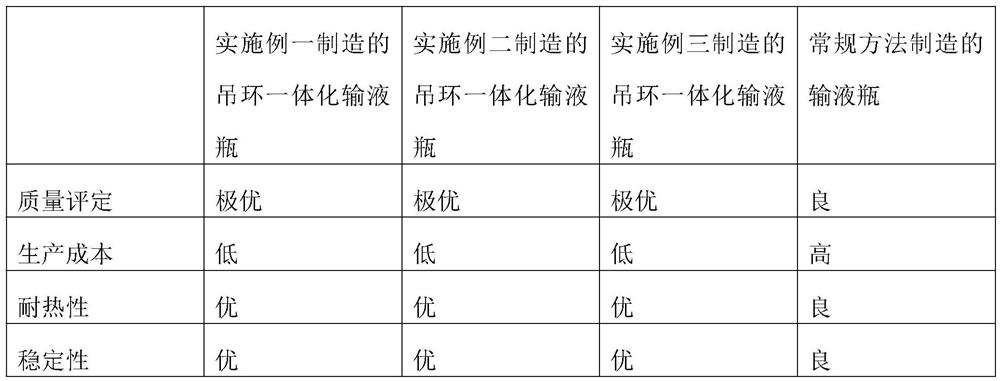

Examples

Embodiment 1

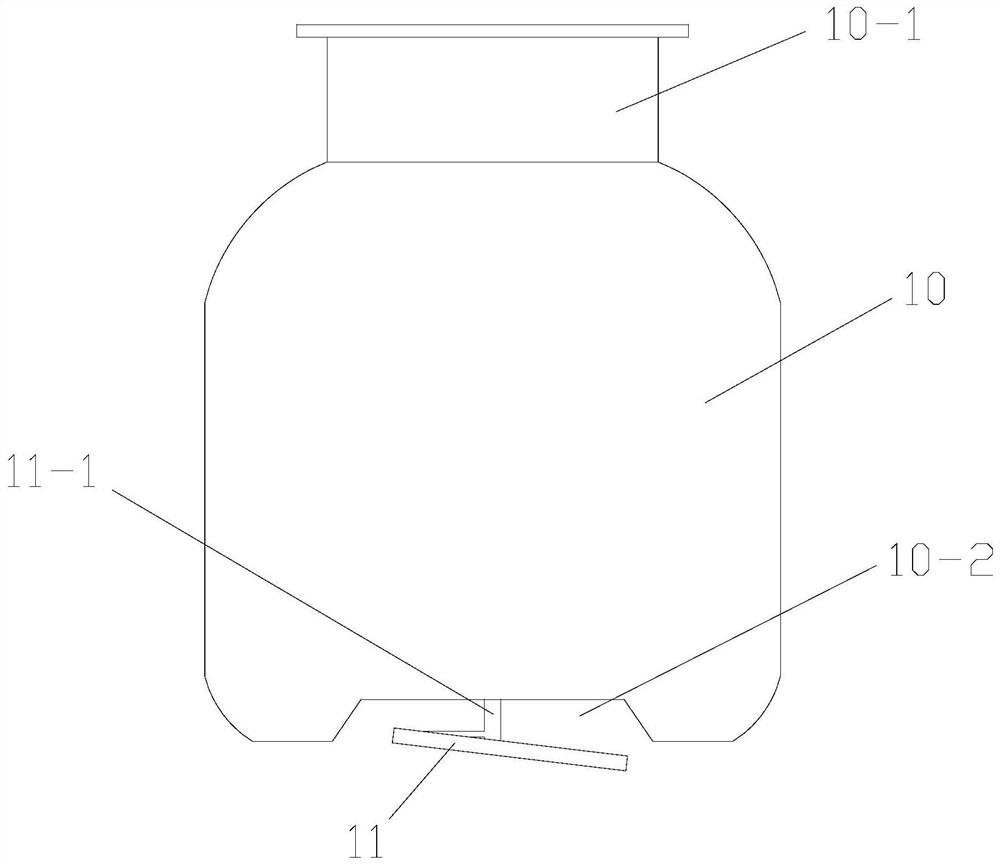

[0031] This ring-integrated infusion bottle includes a bottle body 10 with a bottle opening 10 - 1 , and a ring 11 integrally formed with the bottle body 10 at the bottom of the bottle body 10 .

[0032] The suspension ring 11 and the bottle body 10 are connected by a fixed column 11 - 1 , and the fixed column 11 - 1 is integrally formed with the suspension ring 11 and the bottle body 10 .

[0033] The bottom of the bottle body 10 is provided with a notch 10-2, and the suspension ring 11 is located in the notch 10-2.

[0034] The manufacturing method of the above-mentioned ring-integrated infusion bottle comprises the following steps:

[0035] The first step is injection molding. The mixed raw materials are injected into the ring-integrated preform injection mold to form the preform of the ring-integrated infusion bottle. There is no clamping seam at the connection between the cavity and the ring in the injection-molded preform;

[0036] The second step, pre-blowing, includes...

Embodiment 2

[0044] This ring-integrated infusion bottle includes a bottle body 10 with a bottle opening 10 - 1 , and a ring 11 integrally formed with the bottle body 10 at the bottom of the bottle body 10 .

[0045] The suspension ring 11 and the bottle body 10 are connected by a fixed column 11 - 1 , and the fixed column 11 - 1 is integrally formed with the suspension ring 11 and the bottle body 10 .

[0046] The bottom of the bottle body 10 is provided with a notch 10-2, and the suspension ring 11 is located in the notch 10-2.

[0047] The manufacturing method of the above-mentioned ring-integrated infusion bottle comprises the following steps:

[0048] The first step is injection molding. The mixed raw materials are injected into the ring-integrated preform injection mold to form the preform of the ring-integrated infusion bottle. There is no clamping seam at the connection between the cavity and the ring in the injection-molded preform;

[0049] The second step, pre-blowing, includes...

Embodiment 3

[0057] This ring-integrated infusion bottle includes a bottle body 10 with a bottle opening 10 - 1 , and a ring 11 integrally formed with the bottle body 10 at the bottom of the bottle body 10 .

[0058] The suspension ring 11 and the bottle body 10 are connected by a fixed column 11 - 1 , and the fixed column 11 - 1 is integrally formed with the suspension ring 11 and the bottle body 10 .

[0059] The bottom of the bottle body 10 is provided with a notch 10-2, and the suspension ring 11 is located in the notch 10-2.

[0060] The manufacturing method of the above-mentioned ring-integrated infusion bottle comprises the following steps:

[0061] The first step is injection molding. The mixed raw materials are injected into the ring-integrated preform injection mold to form the preform of the ring-integrated infusion bottle. There is no clamping seam at the connection between the cavity and the ring in the injection-molded preform;

[0062] The second step, pre-blowing, includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com