Preparation method of positive electrode paste for lithium fluorocarbon battery with carbon nanotube as conductive agent

A lithium fluorocarbon battery, carbon nanotube technology, applied in electrode manufacturing, battery electrodes, electrodes of primary batteries, etc., can solve the problems of no electrochemical activity, reduced battery specific energy, poor electrical conductivity, etc., to achieve operation Simple and easy to understand, the effect of improving high and low temperature performance, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

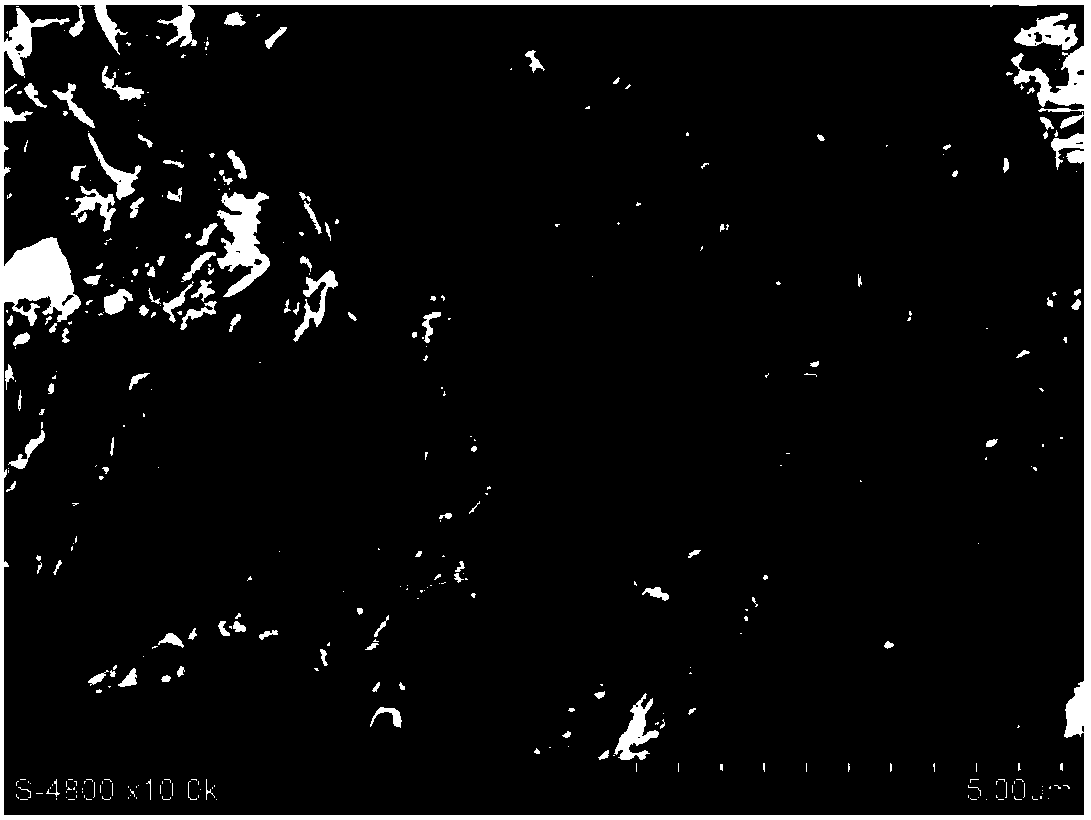

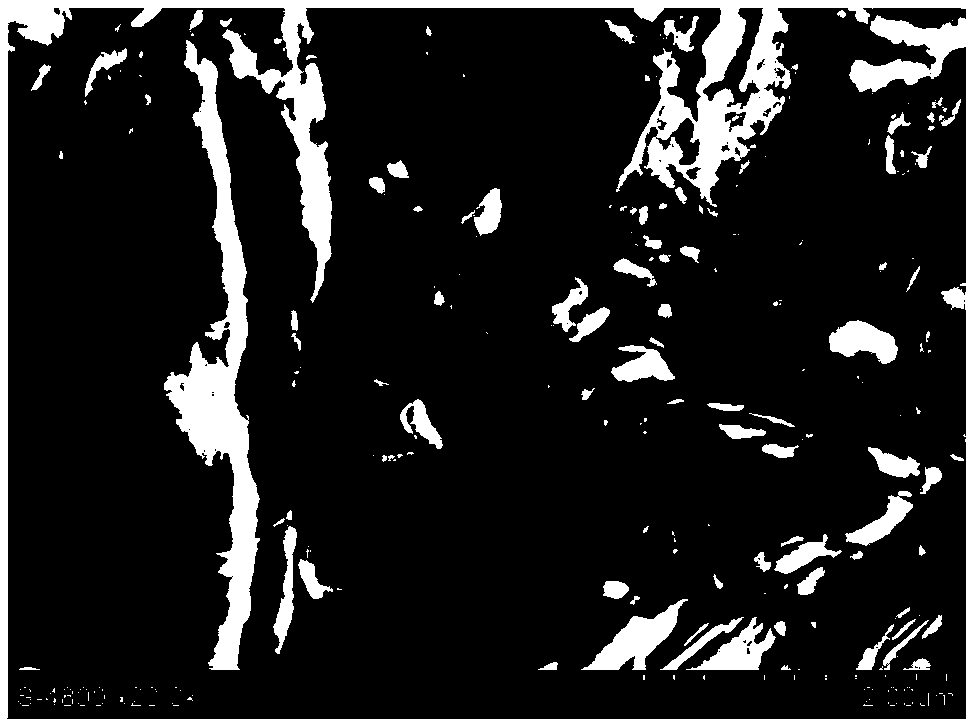

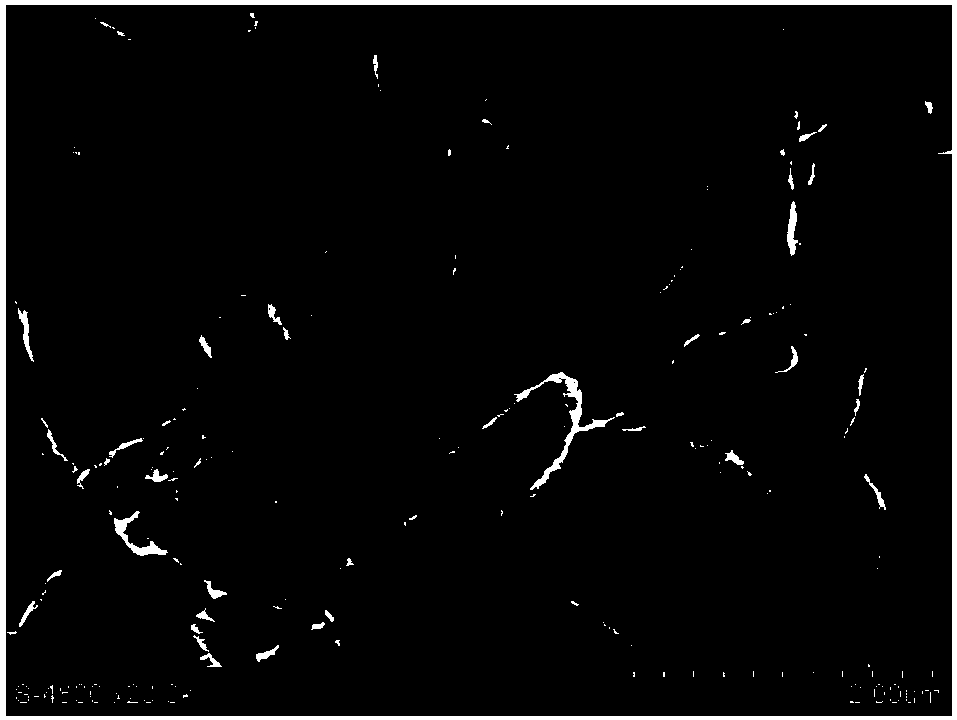

Image

Examples

Embodiment 1

[0034] The preparation method of positive electrode slurry for lithium carbon fluoride battery with carbon nanotubes as conductive agent takes the positive electrode slurry and preparation method using Super P and carbon nanotubes as conductive agent respectively as examples. The slurry formula is shown in the table below.

[0035]

[0036] Homogenization process flow is as follows:

[0037] 1.1# sample takes by weighing 1.2kg fluorocarbon, 80g Super P and 27g sodium carboxymethyl cellulose, 3# sample takes by weighing 1.2kg fluorocarbon and 25g sodium carboxymethyl cellulose and puts it into a double planetary power mixer, with Stir at a low speed of 60 rpm and a high speed of 2000 rpm for 30 minutes;

[0038] 2. Add solvent, then stir until there is no obvious dry powder in the slurry;

[0039] 3. Use low-speed stirring of 60 rpm and high-speed dispersion of 3000 rpm. The stirring time is 5 hours, and the temperature is controlled at 20-55°C. When stirring for 3 hours, ...

Embodiment 2

[0043] The preparation method of positive electrode slurry for lithium carbon fluoride battery with carbon nanotubes as conductive agent takes the positive electrode slurry and the preparation method of adding different amounts of carbon nanotube conductive glue as an example. The slurry formula is shown in the table below.

[0044]

[0045] 3# sample homogenization procedure sees embodiment 1, 2# sample homogenization procedure flow process is as follows:

[0046] 1. Weigh 1.2kg of carbon fluoride and 25g of sodium carboxymethyl cellulose, put them into a double planetary power mixer, stir at a low speed of 65 rpm and a high speed of 3000 rpm for 30 minutes;

[0047] 2. Add solvent, then stir until there is no obvious dry powder in the slurry;

[0048] 3. Use low-speed stirring of 65 rpm and high-speed dispersion of 3500 rpm. The stirring time is 6 hours, and the temperature is controlled at 20-55°C. When stirring for 3 hours, 2# sample is added with conductive adhesive c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com