Flexible color micro-LED manufacturing method and prepared product

A flexible and color technology, applied in the direction of instruments, electrical components, electric solid devices, etc., can solve the problems of huge amount of chips, color conversion, transfer, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

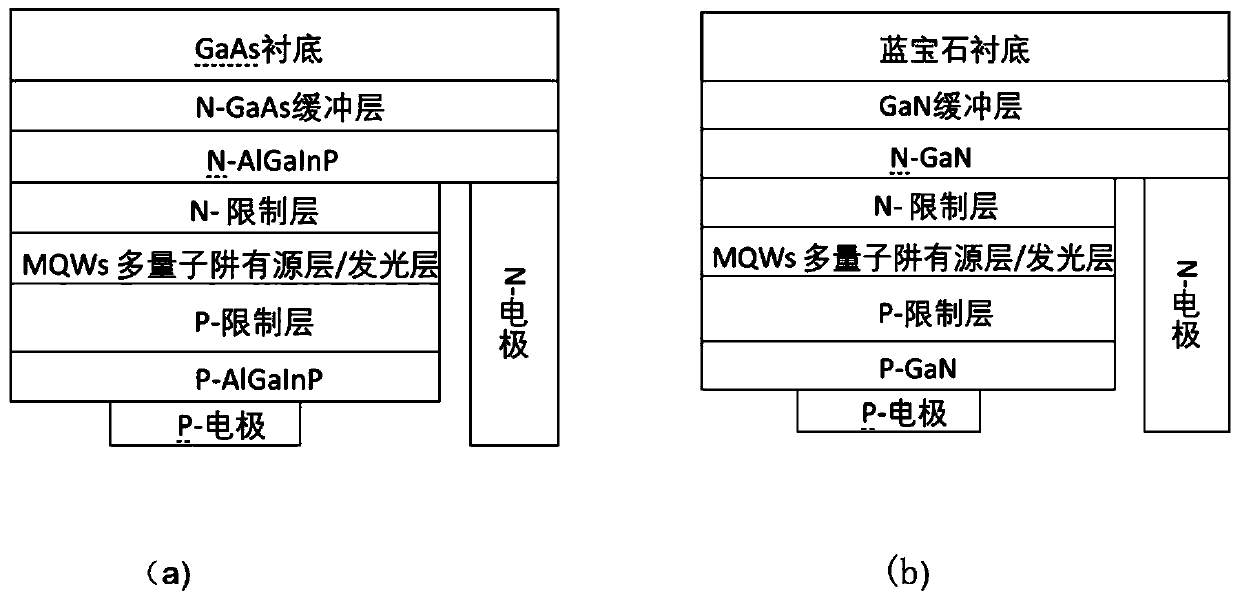

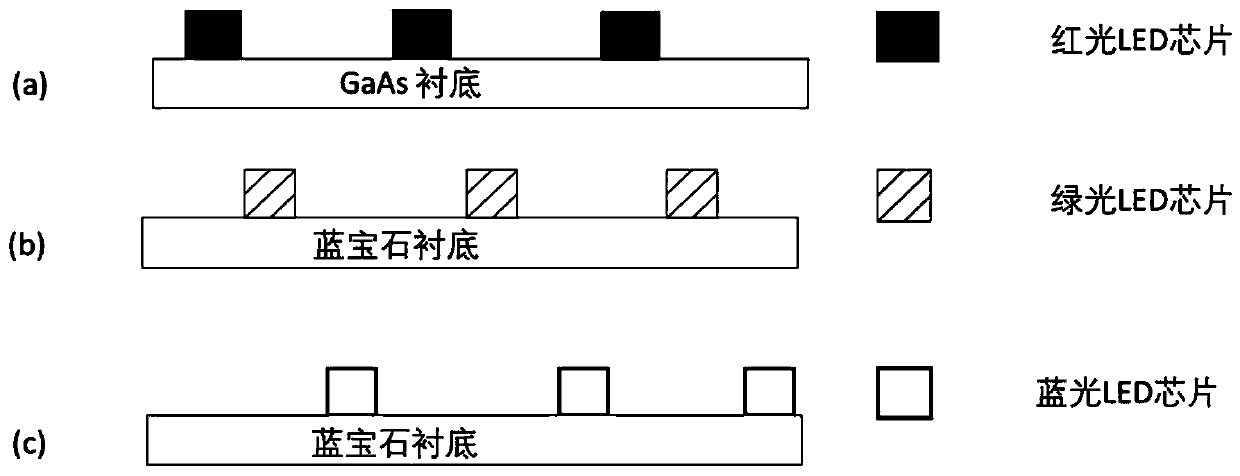

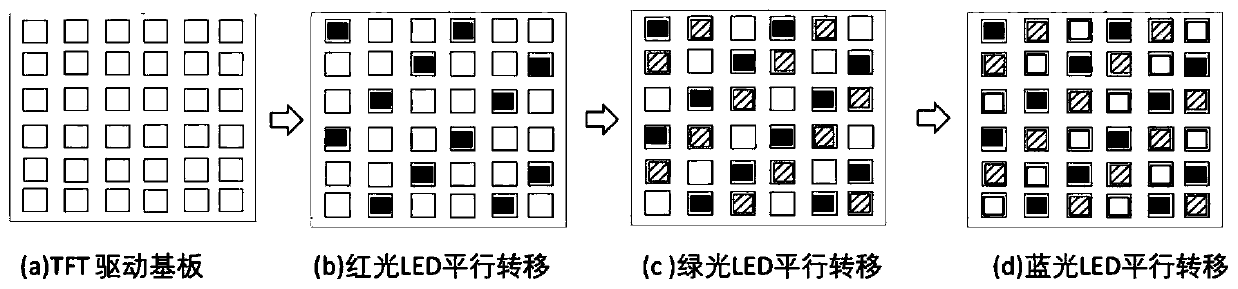

[0024] Step 1. Prefabricate a patterned red light flip-chip microchip (pixel) on the GaAs substrate LED wafer (including epitaxial layer) by photoetching or mutual induction coupled plasma etching (ICP) (see attached figure 1 (a), with a size of 8 μm. The fabricated Micro-LED chip is annealed in a vacuum furnace.

[0025] Step 2. Make patterned GaN-based green and blue flip-chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photoetching or inductively coupled plasma etching (ICP) respectively (see attached figure 1 (b) and (c)), with a size of 8 μm. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0026] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0027] Step 4, the sapphire substrates on the green light and blue light microchips are respectively peeled off by laser.

[0028] Step 5. Translate the pattern-shaped ...

Embodiment 2

[0034] Step 1. Prefabricate a patterned red light flip-chip microchip (pixel) on the GaAs substrate LED wafer (including epitaxial layer) by photoetching or mutual induction coupled plasma etching (ICP) (see attached figure 1 (a), with a size of 7 µm. The fabricated Micro-LED chip is annealed in a vacuum furnace.

[0035] Step 2. Make patterned GaN-based green and blue flip-chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photoetching or inductively coupled plasma etching (ICP) respectively (see attached figure 1 (b) and (c)), with a size of 7 microns. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0036] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0037] Step 4, the sapphire substrates on the green light and blue light microchips are respectively peeled off by laser.

[0038] Step 5. Translate the pattern-sh...

Embodiment 3

[0044] Step 1. Prefabricate a patterned red light flip-chip microchip (pixel) on the GaAs substrate LED wafer (including epitaxial layer) by photoetching or mutual induction coupled plasma etching (ICP) (see attached figure 1 (a), with a size of 6 μm. The fabricated Micro-LED chip is annealed in a vacuum furnace.

[0045]Step 2. Make patterned GaN-based green and blue flip-chips (pixels) on the sapphire substrate LED wafer (including epitaxial layer) by photoetching or inductively coupled plasma etching (ICP) respectively (see attached figure 1 (b) and (c)), with a size of 6 microns. The green and blue chips produced were annealed in a vacuum furnace respectively.

[0046] Step 3, performing selective etching on the GaAs substrate of the red light microchip to obtain a patterned chip supported by a thin film.

[0047] Step 4, the sapphire substrates on the green light and blue light microchips are respectively peeled off by laser.

[0048] Step 5. Translate the pattern-sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com