Double-lamp-curing white UV inkjet ink and preparation method thereof

An inkjet ink, white technology, applied in the field of dual-lamp curing white UV inkjet ink and its preparation, can solve the problems of easy cracking of relief patterns, high hardness of the film layer, easy to become brittle, etc., and achieve good continuity and smoothness of the ink. , The effect of good storage stability and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

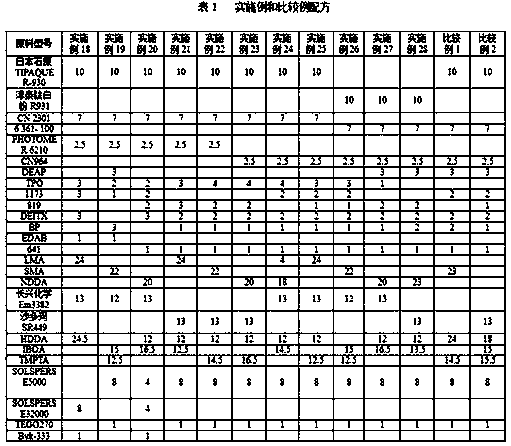

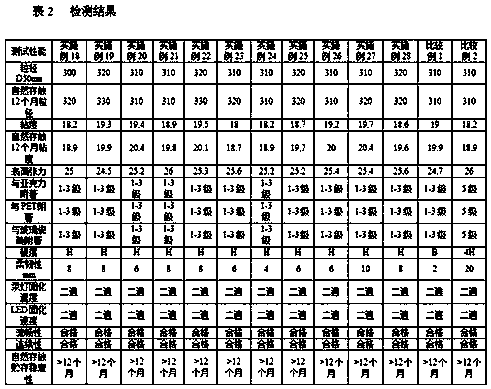

Examples

Embodiment 1

[0024] A double-lamp curable white UV inkjet ink, made of the following raw materials in mass percentage: 5-15% of nano-scale pigments; 3-10% of polyester acrylate oligomers; 2-5% of polyurethane acrylate oligomers ; Photoinitiator 5-20%; Molecular chain contains -(CH 2 ) n - 15-45% of monofunctional or difunctional reactive monomers with structure, n≥5; 5-30% of ethoxylated or propoxylated trifunctional or more reactive monomers; 20-60% of other reactive monomers; Agent 5-15%.

[0025] The average particle size of nanoscale pigments is 50-500nm.

[0026] The polyester acrylate oligomer is a hyperbranched polyester acrylate oligomer, and the urethane acrylate oligomer is an aliphatic urethane acrylate oligomer.

[0027] The photoinitiator consists of Norrish type I initiator, Norrish type II initiator and tertiary amine co-initiator.

[0028] The Norrish I type initiator accounts for 2-15% of the total ink weight, the Norrish II type initiator accounts for 2-10% of the tot...

Embodiment 2

[0035] A double-lamp curable white UV inkjet ink is made of the following raw materials in mass percent: 5 kg of nano-scale pigments; 10 kg of polyester acrylate oligomers; 2 kg of polyurethane acrylate oligomers; 5 kg of photoinitiators; Contains -(CH 2 )n - 15kg of monofunctional or bifunctional reactive monomers with a structure, n=5; 10kg of ethoxylated or propoxylated trifunctional or more reactive monomers; 38kg of other reactive monomers; 15kg of additives.

[0036] The average particle size of nanoscale pigments is 50nm.

[0037] The polyester acrylate oligomer is hyperbranched polyester acrylate oligomer CN 2302, and the urethane acrylate oligomer is aliphatic urethane acrylate oligomer CN929.

[0038] The photoinitiator consists of Norrish I type initiator DEAP, Norrish II type initiator ITX and tertiary amine co-initiator EDAB.

[0039] Norrish I type initiator 2kg, Norrish II type initiator 2kg, tertiary amine co-initiator 1kg.

[0040] Ethoxylated or propoxylat...

Embodiment 3

[0046] A double-lamp curable white UV inkjet ink, made of the following raw materials in mass percent: 5 kg of nanoscale pigments; 3 kg of polyester acrylate oligomers; 2 kg of polyurethane acrylate oligomers; 5 kg of photoinitiators; Contains -(CH 2 ) n - 15kg of monofunctional or bifunctional reactive monomers with a structure, n=6; 5kg of ethoxylated or propoxylated trifunctional or more reactive monomers; 60kg of other reactive monomers; 5kg of additives.

[0047] The average particle diameter of nanoscale pigments is 80nm.

[0048] The polyester acrylate oligomer is hyperbranched polyester acrylate oligomer CN 2301, and the urethane acrylate oligomer is aliphatic urethane acrylate oligomer CN945.

[0049] The photoinitiator is composed of Norrish I type initiator BDMM, Norrish II type initiator DETX and tertiary amine co-initiator 641.

[0050] Norrish I type initiator 2kg, Norrish II type initiator 2kg, tertiary amine co-initiator 1kg.

[0051] Ethoxylated or propoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com