A kind of lithium-air battery extended interlayer melt-spinning preparation process

A lithium-air battery and melt-spinning technology, which is applied in the direction of battery electrodes, electrode manufacturing, fuel cell-type half-cells and primary battery-type half-cells, etc., can solve the problem of single structure of lithium-air batteries, affecting battery energy density, and inability to Improve diaphragm strength and other issues to reduce the risk of internal short circuit, prolong service life and avoid shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

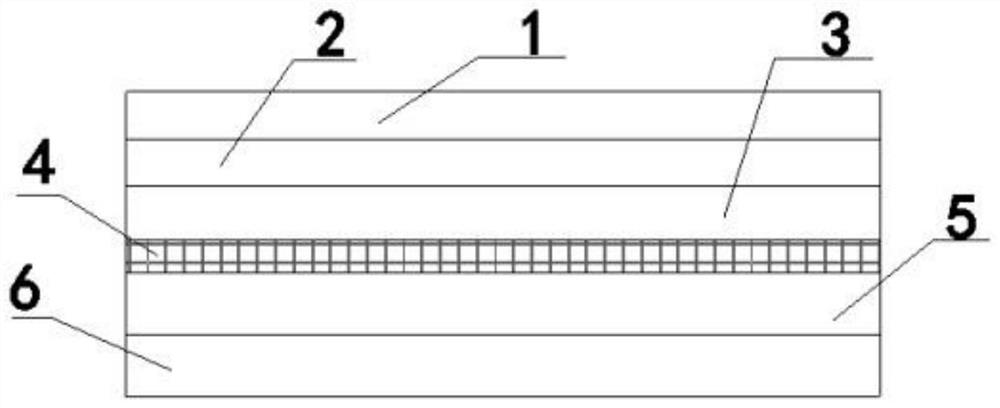

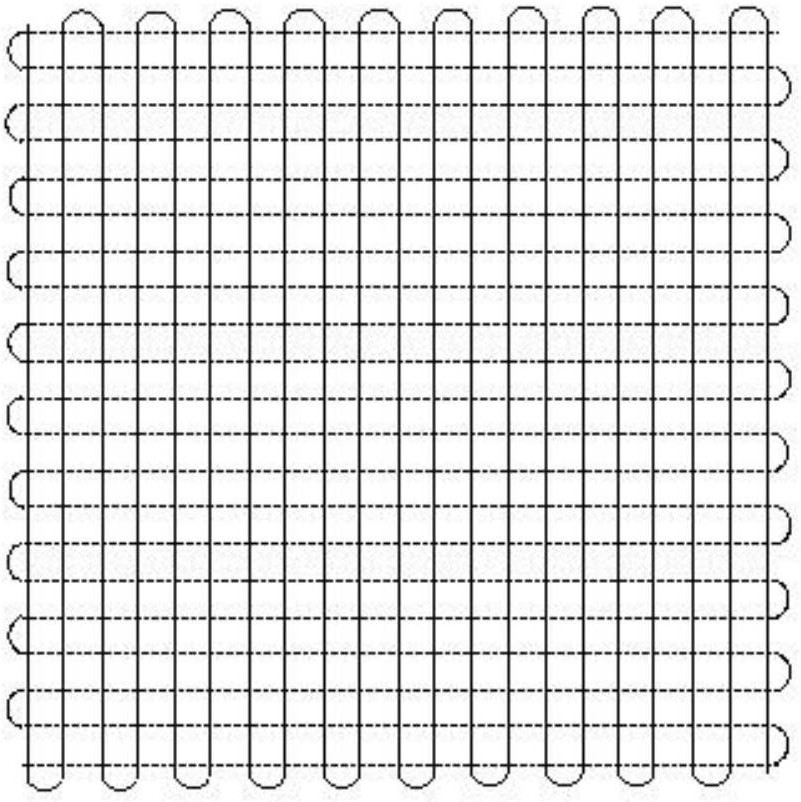

[0029] Embodiment 1: get βMnO 2 0.15g, Ketjen Black 0.35g, EVA 0.5g, melt blending and stirring under heating in a water bath at 90 degrees Celsius to obtain a blend; take αMnO 2 0.4g, 0.4g of Ketjen Black, 0.1g of PVDF, and 0.1g of CaO were dissolved in 15ml of NMP, stirred and blended and placed in a sprayer to obtain a spray material. PVDF-HFP diaphragm is used as a battery diaphragm. Pour the molten blend into an extruder with a heating device. Through extrusion, the blend is pressed out of the spinneret through a metering pump and condensed into thin strips on the HFP diaphragm. , refer to figure 2 , form a mesh layer in an orthogonal manner, and spray a layer of spray after each layer of mesh layer is formed, the amount of spray per square meter of mesh layer is 50ml, and finally attach 3 layers of mesh layer on the diaphragm. The resulting collection of all mesh layers and sprays is the expanded interlayer. Dry the separator with the expanded interlayer in an oven...

Embodiment 2

[0032] Embodiment 2: Take αMnO 2 0.1g, graphene 0.4g, PEG 0.5g, melt blending and stirring under 80 degrees Celsius water bath heating to obtain a blend; take βMnO 2 0.4g, graphene 0.4g, PVDF 0.1g, CaO 0.1g, dissolved in 20ml NMP, stirred and blended and placed in a sprayer to obtain a spray material. The glass fiber mat is used as a battery separator. The molten blend is poured into an extruder with a heating device. Through extrusion, the blend is pressed out of the spinneret through a metering pump and condensed into thin strips on the glass fiber mat. , refer to figure 2 , form a mesh layer in an orthogonal manner, and spray a layer of spray every time 2 mesh layers are formed, the spray volume of the mesh layer per square meter is 60ml, and finally attach 4 layers of mesh layers on the diaphragm. The final collection of the net layer and the spray is the expanded interlayer. Dry the separator with the expanded interlayer in an oven at 50°C for 24 hours, take it out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com