A kind of aromatic polyamide slurry, porous diaphragm and preparation method thereof

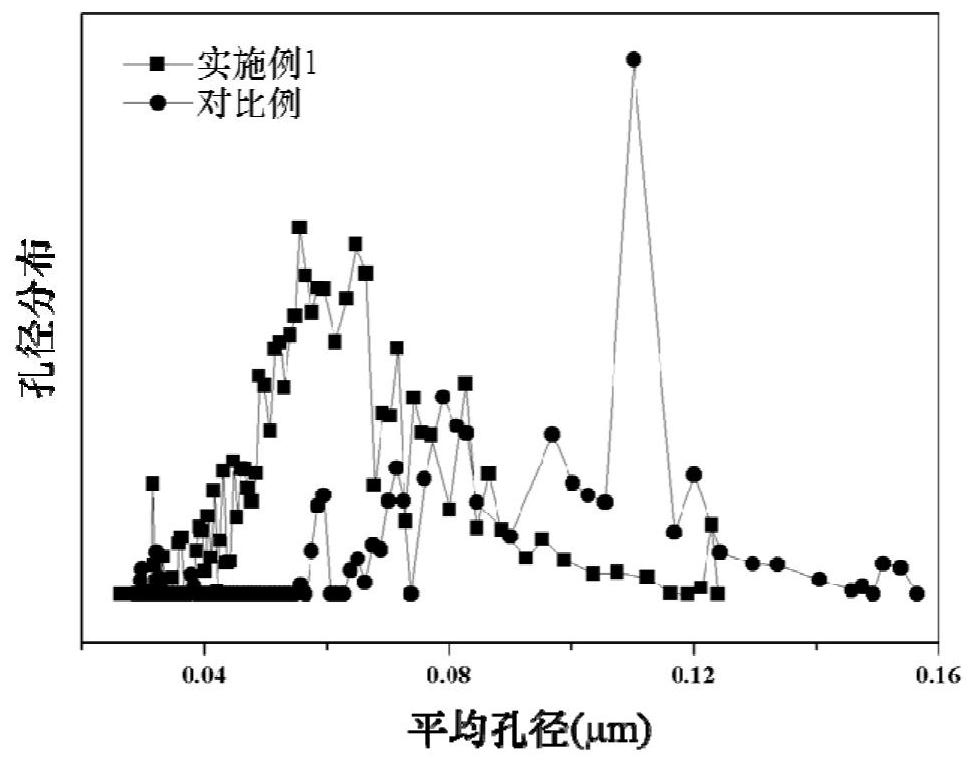

An aramid and slurry technology, applied in structural parts, battery pack parts, electrical components, etc., can solve the problems of difficult control of pore size uniformity, high water absorption rate of porous membrane, uneven pore size, etc. Reduction of core capacity and cycle performance, reduction of suppression capacity and cycle performance, good effect of pore size uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Aramid slurry preparation

[0073] Mix polym-phenylene isophthalamide, N,N-dimethylformamide and lithium chloride at a mass ratio of 18.4:76.8:4.8 to obtain a transparent aromatic polyamide solution; add reactive Add adipoyl chloride, and stir at room temperature for 2 hours to form polym-phenylene isophthalamide: N,N-dimethylformamide: lithium chloride: adipoyl chloride with a mass ratio of 17.8:74.3 : 4.6: 3.3 aramid slurry, the rotational viscosity of the obtained aramid slurry is 488,000cp.

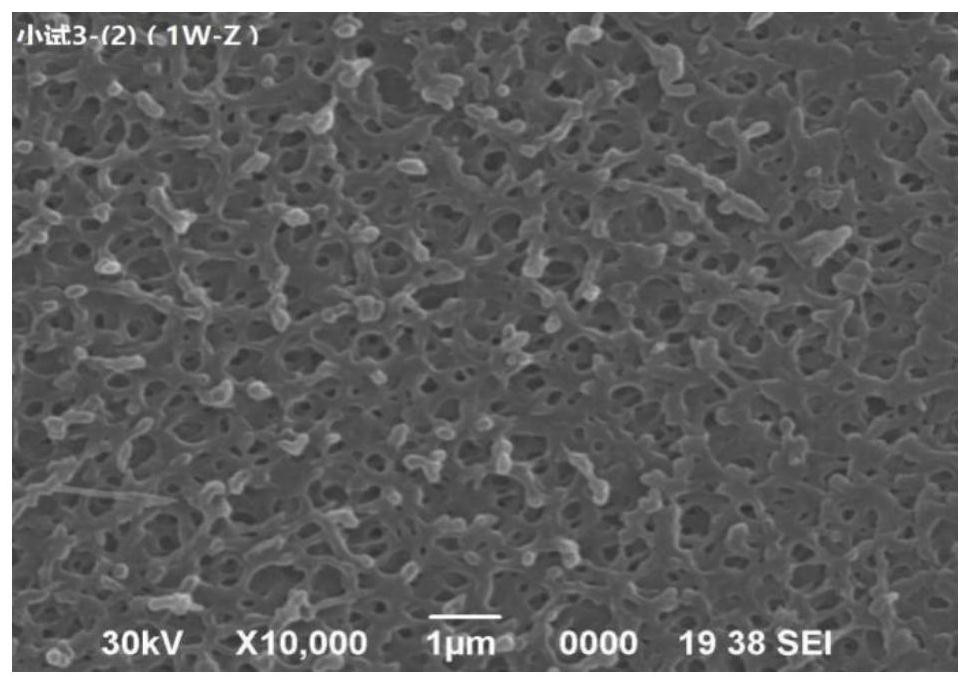

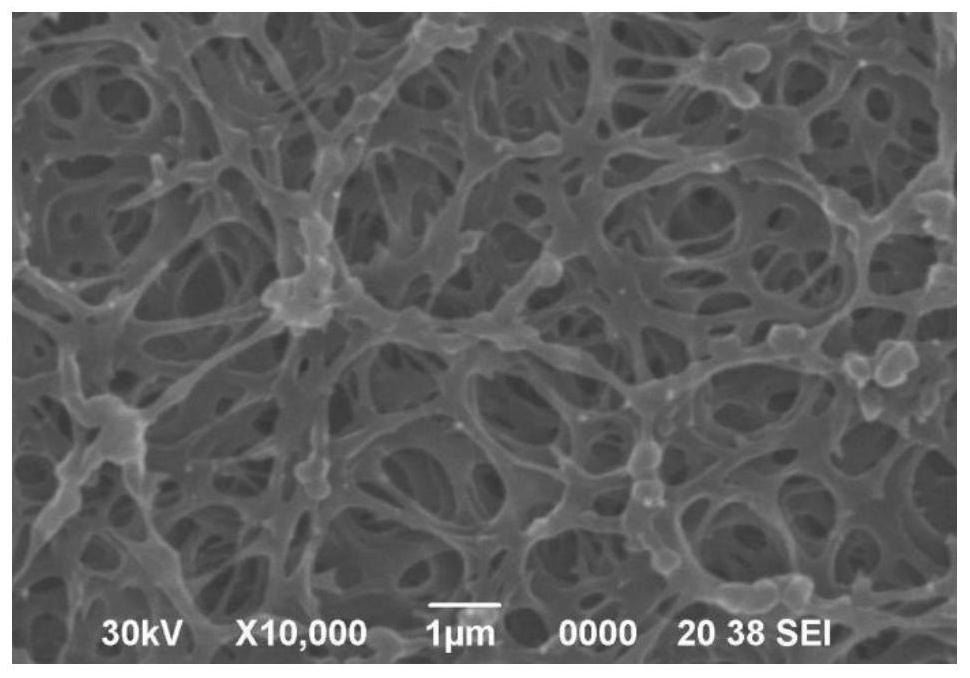

[0074] (2) Preparation of porous diaphragm

[0075] Extrude the aramid slurry onto the tetrafluoro chain belt to form a liquid film with a thickness of about 20um; immerse the tetrafluoro chain belt together with the liquid film into water and N,N-dicarbonate with a mass ratio of 25:75 A coagulation bath composed of methylformamide, the temperature of the coagulation bath is 30°C, stay in the coagulation bath for 2 minutes, and the liquid film forms a film in the coagulat...

Embodiment 2

[0081] Same as Example 1, except that the mass ratio of polym-phenylene isophthalamide, N,N-dimethylformamide, lithium chloride, and adipoyl chloride in the aramid slurry is replaced by 19.8:75.2 :2.9:2.1, the rotational viscosity of the obtained aramid slurry was 546,000cp.

[0082] The obtained separator had a porosity of 52.3%, an air permeability of 94s / 100cc, a moisture content of 3620ppm, an average pore diameter of 47.5nm, and an average pore diameter standard deviation of 0.023.

Embodiment 3

[0084] Same as in Example 1, except that poly-p-phenylene terephthalamide is used instead of poly-m-phenylene isophthalamide, and the rotational viscosity of the obtained aramid slurry is 643,000 cp. The obtained diaphragm had a porosity of 61.4%, an air permeability of 74s / 100cc, a moisture content of 3240ppm, and an average pore diameter of 93.8nm, with a standard deviation of the average pore diameter of 0.021.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com