Strontium magnesium silicate nanomaterial and preparation method and application thereof

A technology of strontium magnesium silicate and nanomaterials, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of poor contact between active materials and current collectors, imperfect silicon-based materials, and battery performance decline. Achieve the effects of less investment in equipment, low cost of raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

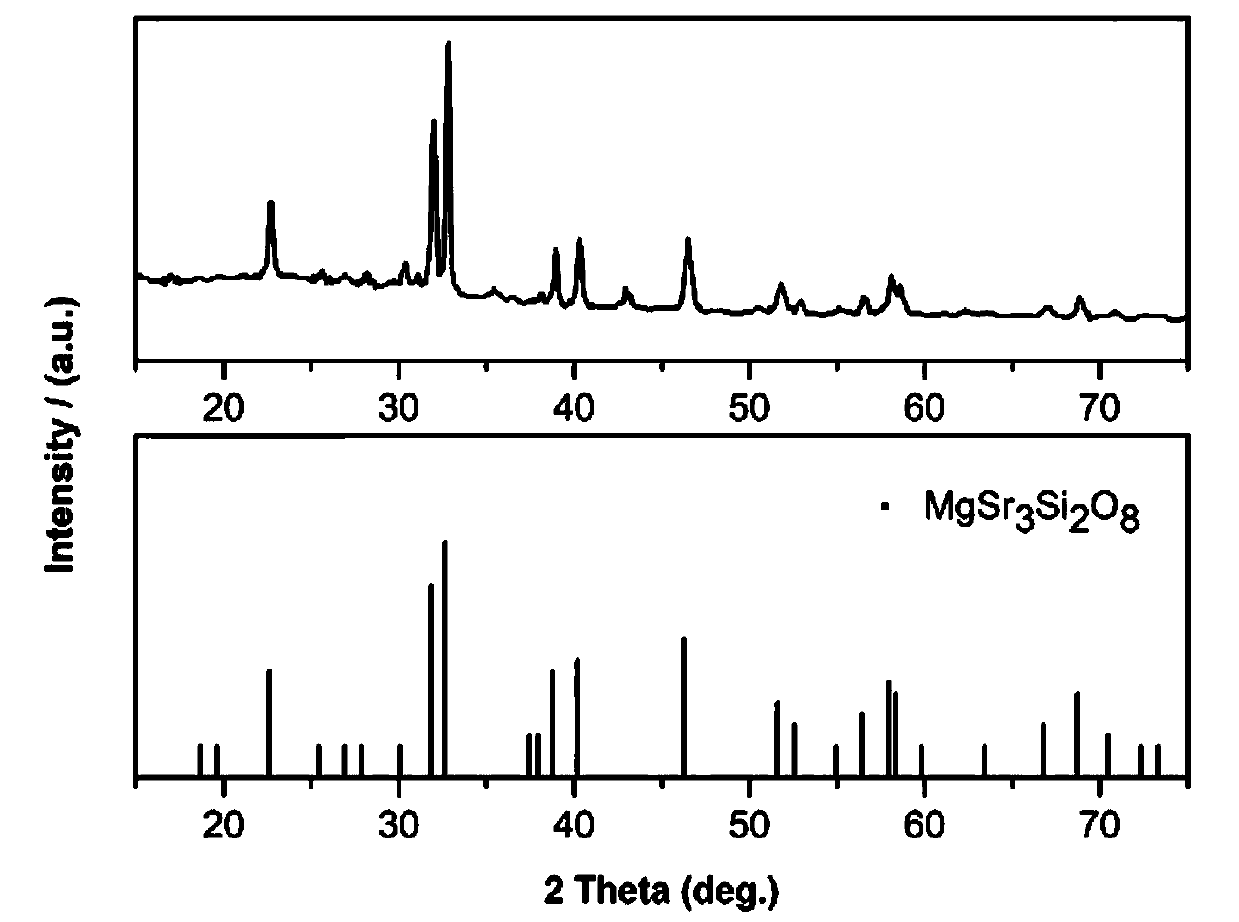

[0017] Weigh 1.0mmol magnesium acetate tetrahydrate ((CH 3 COO) 2 Mg·4H 2 O), 3.0mmol strontium acetate (CH 3 COOSr), 2.0mmol tetraethyl silicate (SiC 8 h 20 o 4 ) and 4.0mmol urea (CO(NH 2 ) 2 ) was dissolved in 20mL ethanol aqueous solution (1:1, V / V), and stirred for 30min. Then the obtained solution was transferred to a reaction kettle and reacted at a constant temperature in an oven at 140° C. for 24 hours. The precipitate was filtered and dried to obtain a white powder. Put the obtained powder in a crucible, calcined in a muffle furnace at 500°C for 4 hours, and at 900°C for 2 hours, and then naturally cooled to room temperature to obtain white strontium magnesium silicate MgSr 3 Si 2 o 8 nanomaterials. will get MgSr 3 Si 2 o 8 Nanomaterials are subjected to powder X-ray diffraction XRD test ( figure 1 ), figure 1 shows that the as-prepared material with MgSr 3 Si 2 o 8 Corresponding to the X-ray diffraction peak spectrum; Scanning electron microscope ...

Embodiment 2

[0019] Weigh 0.5mmol magnesium acetate tetrahydrate ((CH 3 COO) 2 Mg·4H 2 O), 1.5mmol strontium acetate (CH 3 COOSr), 1.0mmol tetraethyl silicate (SiC 8 h 20 o 4 ) and 2.0mmol urea (CO(NH 2 ) 2 ) was dissolved in 15 mL of ethanol in water (1:1, V / V), and stirred for 30 min. Then the obtained solution was transferred to a reaction kettle and reacted at a constant temperature in an oven at 150° C. for 24 hours. The precipitate was filtered and dried to obtain a white powder. Put the obtained powder in a crucible, calcined in a muffle furnace at 500°C for 3 hours, and at 900°C for 3 hours, and then naturally cooled to room temperature to obtain white strontium magnesium silicate MgSr 3 Si 2 o 8 nanomaterials.

Embodiment 3

[0021] Weigh 2.0mmol magnesium acetate tetrahydrate ((CH 3 COO) 2 Mg·4H 2 O), 6.0mmol strontium acetate (CH 3 COOSr), 4.0mmol tetraethyl silicate (SiC 8 h 20 o 4 ) and 8.0mmol (0.480g) urea (CO(NH 2 ) 2 ) was dissolved in 15 mL of ethanol in water (1:1, V / V), and stirred for 30 min. Then the obtained solution was transferred to a reaction kettle and reacted at a constant temperature in an oven at 160° C. for 24 hours. The precipitate was filtered and dried to obtain a white powder. Put the obtained powder in a crucible, calcined in a muffle furnace at 500°C for 3.5 hours, and at 900°C for 2.5 hours, and then naturally cooled to room temperature to obtain white strontium magnesium silicate MgSr 3 Si 2 o 8 nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com