Cleaning method of melt pipeline and application

A melt pipeline and pipeline technology, which is applied to cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of inability to achieve cleaning effect and impermeability of steam, and achieve the reduction of foreign matter, easy operation, and improved product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] The cleaning method provided in this embodiment specifically includes the following steps:

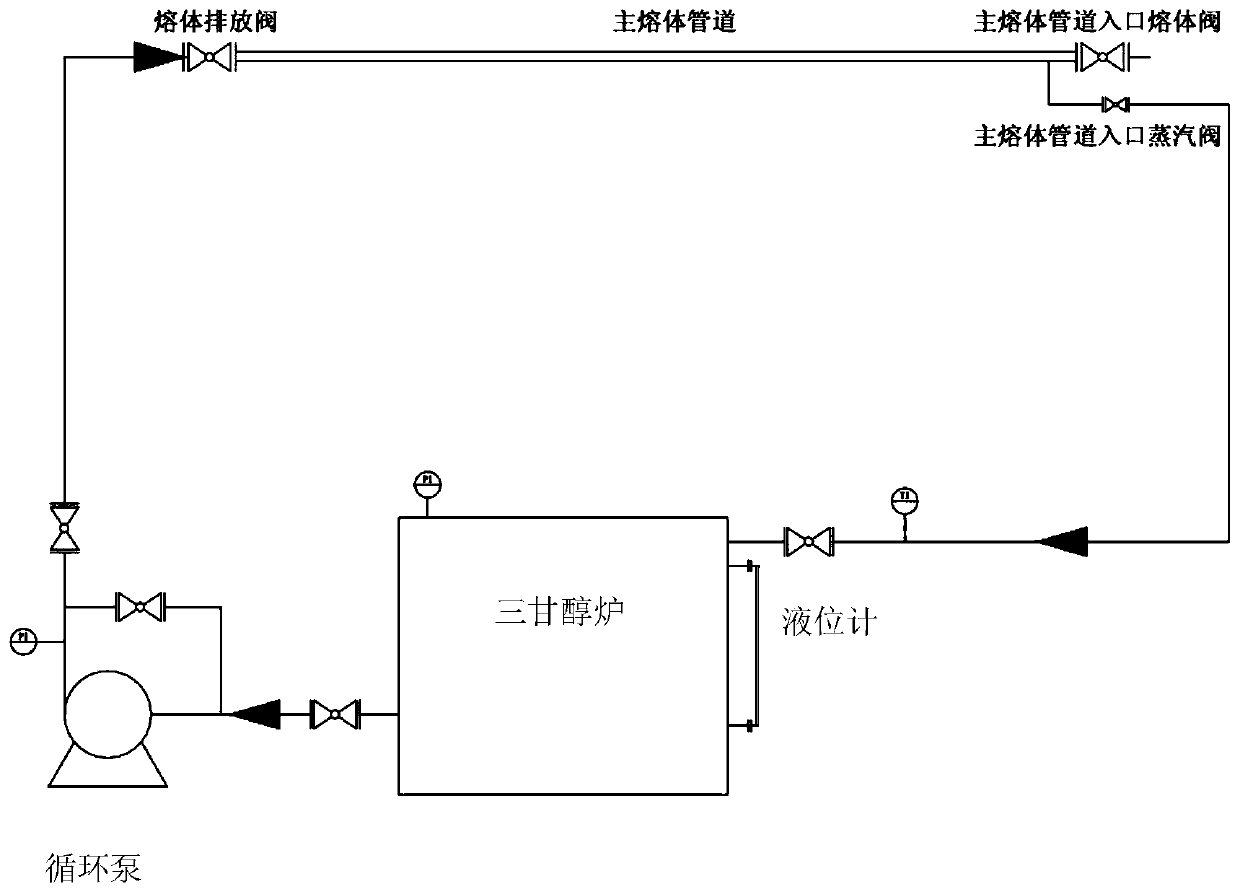

[0066] 1. Before cleaning, press figure 1 Connect the recirculation lines as shown in the cleaning flow chart.

[0067] 2. Add appropriate amount of triethylene glycol into the cleaning furnace from the feed port through the barrel pump.

[0068] 3. Start the triethylene glycol circulating pump at room temperature, slowly open the pump outlet valve, fill the melt pipeline with triethylene glycol, and when the pipeline is filled and the liquid level in the cleaning furnace no longer drops, check whether there is any leakage in the circulating pipeline. After filling the pipeline, the liquid level in the cleaning furnace tank should not be lower than the heater (the liquid level gauge should not be lower than 25%).

[0069] 4. Turn on the instrument switch of the control cabinet and set the cleaning program:

[0070] Heating stage: the range is as follows, and at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com