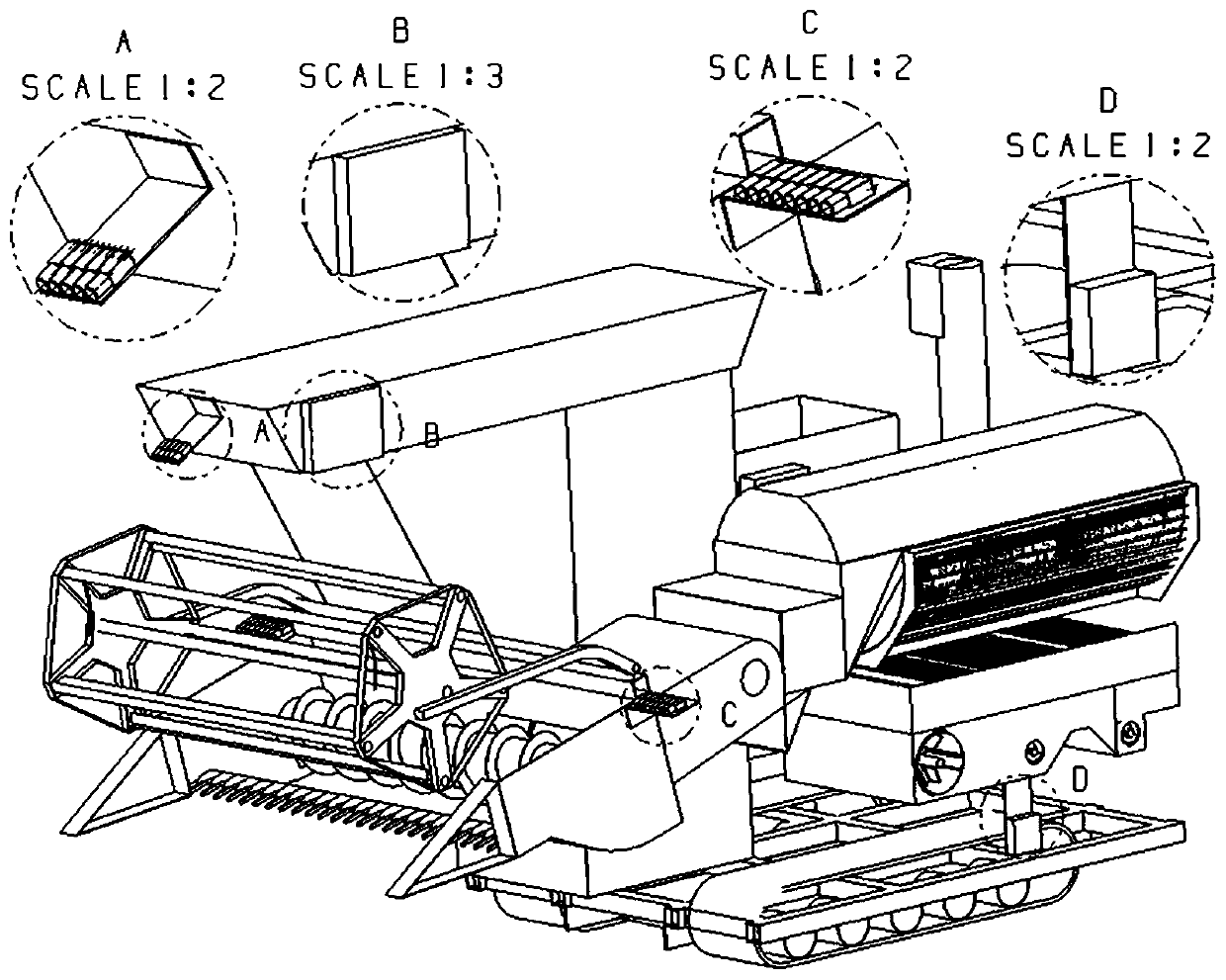

Control device and control method for operating parameters of cutting table of combine harvester

A combine harvester and operating parameter technology, which is applied to harvesters, agriculture, cutters, etc., can solve problems such as changing weather, uneven ground conditions, manual control accuracy and reliability, etc., to reduce control intensity, The effect of improving the level of intelligence and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] Embodiment 1: An embodiment of adjusting the reel speed and cutter frequency.

[0122] The reel and cutter are respectively connected to their respective hydraulic motors through transmission chains, and the hydraulic motors are connected to the hydraulic pumps through proportional valves. The control module outputs analog signals to control the proportional valves, thereby controlling the speed of the hydraulic motors, and finally realizes the speed and speed of the reel. Adjustment of cutter frequency.

Embodiment 2

[0123] Embodiment 2: an embodiment of header height adjustment.

[0124] The header is connected to the hydraulic cylinder, the hydraulic cylinder is connected to the hydraulic pump through the flow control valve and the direction control valve, the flow control valve controls the speed of the hydraulic cylinder movement, the direction control valve controls the direction of the hydraulic cylinder movement, and the output signal of the control module controls the flow control valve And the directional control valve, so as to control the movement of the hydraulic cylinder, and finally realize the adjustment of the header height.

Embodiment 3

[0125] Embodiment 3: An example of adjusting the position of the reel.

[0126] Two groups of electric push rods, each group has one electric push rod on the left and right; one group is vertically fixed on the header frame, and one end is connected with the reel support frame; the other group is parallelly fixed on the reel support frame; each An electric push rod receives the analog signal from the control module, and pushes the reel to move up and down, back and forth, and finally realizes the adjustment of the position of the reel.

[0127] Those skilled in the art should understand that the embodiments of the present invention may be provided as methods, systems, or computer program products. Accordingly, the present invention can take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present invention may take the form of a computer program product embodied on one or m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com