Polymer emulsion and preparation method thereof

A technology of polymer emulsion and polymer solution, which is applied in the field of polymer emulsion, can solve problems such as poor emulsification effect and poor product stability, and achieve the effects of avoiding demulsification, good stability, and saving industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

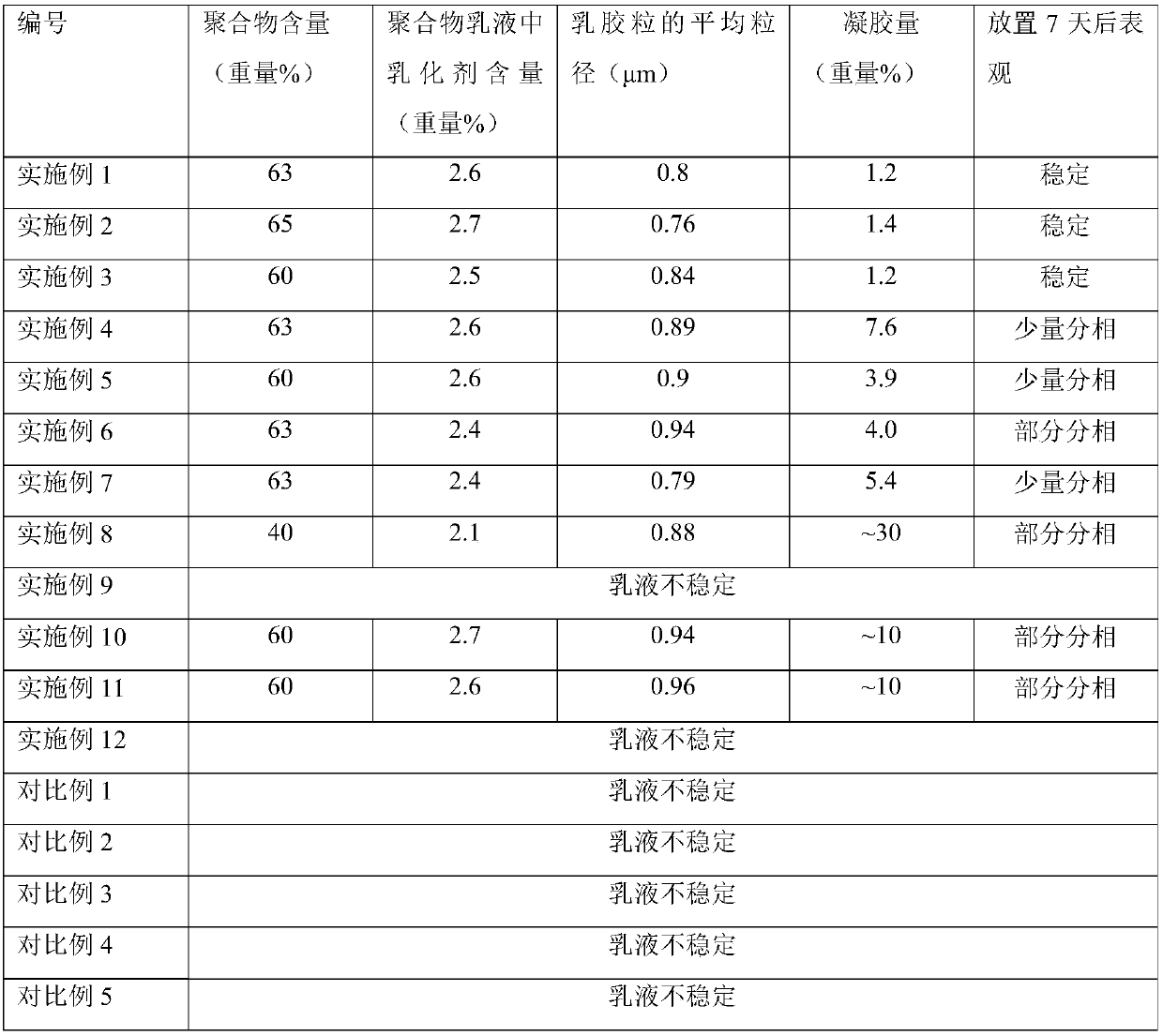

Examples

preparation example Construction

[0016] According to a first aspect of the present invention, the present invention provides a method for preparing a polymer emulsion, the method comprising an emulsification step and at least one emulsion separation step,

[0017] In the emulsification step, mixing a polymer solution containing an olefin polymer and an organic solvent with an aqueous solution containing an emulsifier, and emulsifying the obtained mixed solution to obtain an emulsion;

[0018] The step of separating and concentrating the emulsion includes successive organic solvent removal sub-steps and centrifugation sub-steps. In the organic solvent removal sub-step, the emulsion is subjected to at least one distillation to remove part of the organic solvent in the emulsion. solvent to obtain a dilute emulsion, and in the centrifugal separation sub-step, the dilute emulsion is subjected to at least one centrifugation;

[0019] The emulsifier is an anionic emulsifier.

[0020] According to the method of the ...

preparation example 1

[0083] In this preparation example, all reagents and reactors were used after anhydrous and oxygen-free treatment.

[0084] Using VCl 4 / AlEt 2 Cl catalyst system, using n-hexane as a solvent to prepare a glue solution Y1 with a concentration of 16 wt%.

[0085] After measurement, the content of structural units derived from ethylene in the ethylene-propylene copolymer is 70 mol%, the weight average molecular weight is 400,000, and the molecular weight distribution is 3.1.

preparation example 2

[0087] Using VCl 4 / AlEt 2 Cl catalyst system, using n-pentane as a solvent to prepare a glue solution Y2 with a concentration of 11wt%.

[0088] After measurement, the content of structural units derived from ethylene in the ethylene-propylene copolymer is 65 mol%, the weight average molecular weight is 360,000, and the molecular weight distribution is 3.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com