Bridge prestressed duct grouting material and preparation method thereof

A tunnel grouting and prestressing technology, applied in the field of prestressed construction, can solve the problems of prolonging the corrosion rate of steel strands and unable to completely prevent the contact of steel strands

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

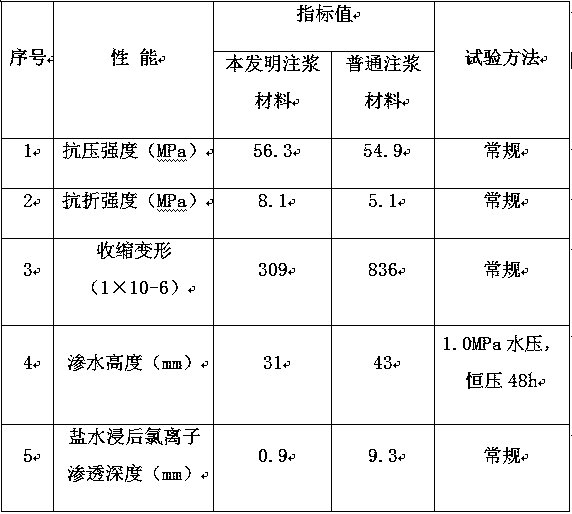

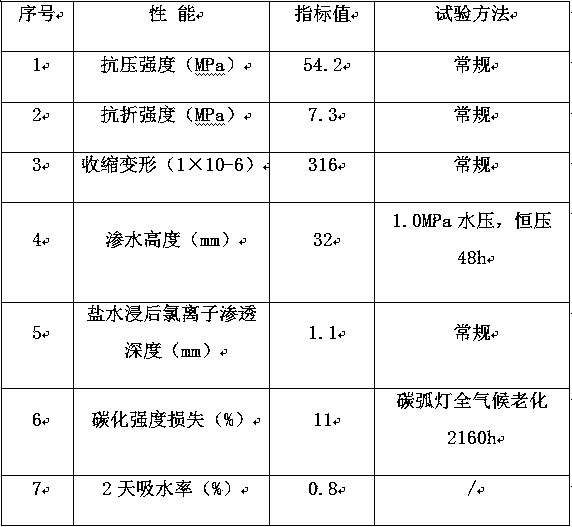

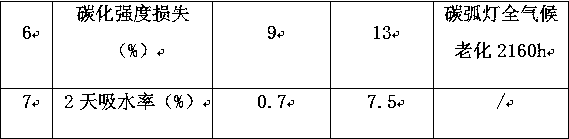

Examples

Embodiment 1

[0028] Embodiment 1: A bridge prestressed channel grouting material: it is composed of component A, cement, water, micro-expansion agent, and water reducer in mass ratio. Its preparation step is divided into two parts, and its one step is the preparation of component A, and its preparation step is:

[0029] a. Mix 15kg of AMP-95 buffer solution with 30kg of water, stir quickly until uniform, and blow nitrogen for 20-30min;

[0030] b. On the basis of step a, add 5kg sodium polymethacrylate and 6kg amino-modified celery paddle, heat to 75°C, and stir at 75°C for 15-20min;

[0031] c. On the basis of step b, add 7kg of nano-silica, 8kg of superfine iron oxide red, heat to 85°C, stir at 85°C for 15-20min, then add 4kg of chloroether resin, 7kg of acrylate, and stir until uniform, keep warm for 30-60min;

[0032] d. Add ammonia water to adjust the pH value to 7-8 to obtain component A;

[0033] The second step is the production of bridge prestressed channel grouting material. I...

Embodiment 2

[0034] Embodiment 2: A bridge prestressed channel grouting material: it is composed of component A, cement, water, micro-expansion agent, and water reducer in mass ratio. Its preparation step is divided into two parts, and its one step is the preparation of component A, and its preparation step is:

[0035] a. Mix 20kg of AMP-95 buffer solution with 40kg of water, stir quickly until uniform, and blow nitrogen for 20-30min;

[0036] b. On the basis of step a, add 8kg sodium polymethacrylate and 10kg amino-modified celery paddle, heat to 75°C, and stir at 75°C for 15-20min;

[0037] c. On the basis of step b, add 10kg of nano-silica, 12kg of superfine iron oxide red, heat to 85°C, stir at 85°C for 15-20min, then add 7kg of chloroether resin, 13kg of acrylate, and stir until uniform, keep warm for 30-60min;

[0038] d. Add ammonia water to adjust the pH value to 7-8 to obtain component A;

[0039] The second step is the production of bridge prestressed channel grouting materia...

Embodiment 3

[0040] Embodiment 3: A bridge prestressed channel grouting material: it is composed of component A, cement, water, micro-expansion agent, and water reducer in mass ratio. Its preparation step is divided into two parts, and its one step is the preparation of component A, and its preparation step is:

[0041] a. Mix 17.5kg of AMP-95 buffer solution with 35kg of water, stir quickly until uniform, and blow nitrogen for 20-30min;

[0042] b. On the basis of step a, add 6.5kg sodium polymethacrylate and 8kg amino-modified celery paddle, heat to 75°C, and stir at 75°C for 15-20min;

[0043] c. On the basis of step b, add 8.5kg of nano-silica, 10kg of superfine iron oxide red, heat to 85°C, stir at 85°C for 15-20min, then add 6.5kg of chloroether resin, 10kg of acrylate , stir until uniform, keep warm for 30-60min;

[0044] d. Add ammonia water to adjust the pH value to 7-8 to obtain component A;

[0045] The second step is the production of bridge prestressed channel grouting mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com