System and method for recovering calcium carbonate and sulfur by calcining gypsum

A calcium carbonate and calcination technology, applied in the preparation/purification of calcium carbonate/strontium/barium, sulfur, etc., can solve the problems of limiting the application scope of sulfur resources, difficulty in storing and transporting sulfuric acid, affecting the stability of the sulfur market, etc. Chemical utilization, improve the utilization rate of raw materials, and prevent the effect of over-burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

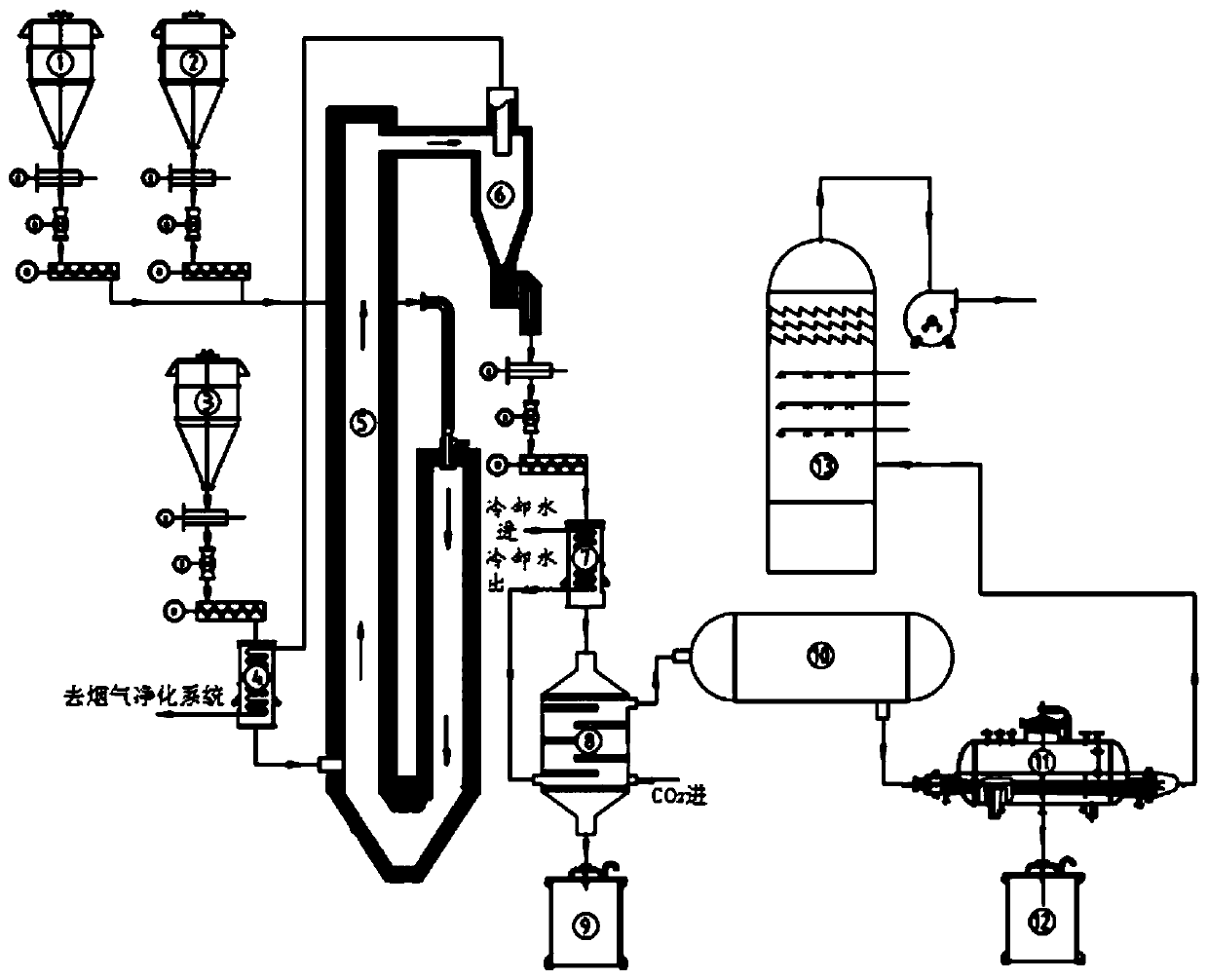

[0054] A system for recovering calcium carbonate and sulfur by calcination of gypsum, including: coal gasification-calcination U-shaped furnace 5, H 2 O-CO 2 Processor 8, Claus reactor 10, the coal gasification section on the right side of the coal gasification-calcination U-shaped furnace 5 is connected to the calcium-based material storage bin 1 and the coal powder storage bin 2 respectively, and the coal gasification-calcination U-shaped The calcining section on the left side of the U-shaped furnace 5 is connected to the gypsum storage bin 3, the top of the calcining section on the left side of the coal gasification-calcination U-shaped furnace 5 is connected to the high-temperature separator 6, and the bottom of the high-temperature separator 6 is cooled with calcium sulfide-calcium oxide Device 7, H 2 O-CO 2 Processor 8, calcium carbonate storage bin 9 are connected successively, and described H 2 O-CO 2The processor 8 is also connected to a Claus reactor 10 , and the...

Embodiment 2

[0059] A system for recovering calcium carbonate and sulfur by calcination of gypsum, including: coal gasification-calcination U-shaped furnace 5, H 2 O-CO 2 Processor 8, Claus reactor 10, the coal gasification section on the right side of the coal gasification-calcination U-shaped furnace 5 is connected to the calcium-based material storage bin 1 and the coal powder storage bin 2 respectively, and the coal gasification-calcination U-shaped The calcining section on the left side of the U-shaped furnace 5 is connected to the gypsum storage bin 3, the top of the calcining section on the left side of the coal gasification-calcination U-shaped furnace 5 is connected to the high-temperature separator 6, and the bottom of the high-temperature separator 6 is cooled with calcium sulfide-calcium oxide Device 7, H 2 O-CO 2 Processor 8, calcium carbonate storage bin 9 are connected successively, and described H 2 O-CO 2 The processor 8 is also connected to a Claus reactor 10 , and th...

Embodiment 3

[0064] A system for recovering calcium carbonate and sulfur by calcination of gypsum, including: coal gasification-calcination U-shaped furnace 5, H 2 O-CO 2 Processor 8, Claus reactor 10, the coal gasification section on the right side of the coal gasification-calcination U-shaped furnace 5 is connected to the calcium-based material storage bin 1 and the coal powder storage bin 2 respectively, and the coal gasification-calcination U-shaped The calcining section on the left side of the U-shaped furnace 5 is connected to the gypsum storage bin 3, the top of the calcining section on the left side of the coal gasification-calcination U-shaped furnace 5 is connected to the high-temperature separator 6, and the bottom of the high-temperature separator 6 is cooled with calcium sulfide-calcium oxide Device 7, H 2 O-CO 2 Processor 8, calcium carbonate storage bin 9 are connected successively, and described H 2 O-CO 2 The processor 8 is also connected to a Claus reactor 10 , and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com