A kind of fe (iii) base catalyst and its preparation method and application

A catalyst and catalyst carrier technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low energy conversion efficiency and low oil yield, and achieve excellent catalyst activity, high activity, high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

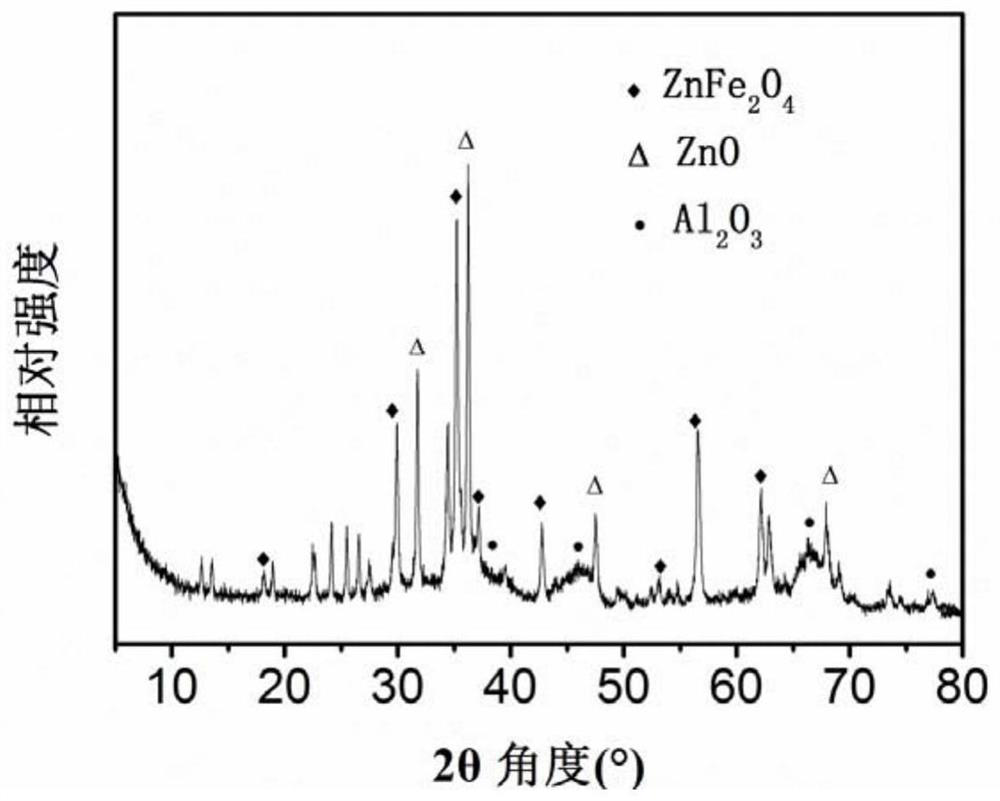

[0024] 31kg of industrial grade FeSO 4 ·7H 2 O. 30kg ZnSO 4 ·7H 2 O was dissolved in 2 tons of tap water, and 400kg of active Al was added to the resulting mixed salt solution 2 o 3The powder is made into a suspension, which is then introduced into the factory instrument air and stirred, and at the same time, a 2% ammonia solution is added dropwise to control the pH of the solution to 6.5, and the reaction is carried out at 20°C for 6 hours. Dry at 200°C for 24h, then bake at 800°C for 1h to obtain active Al 2 o 3 For the supported Fe(III)-based catalyst containing Zn(II), the loading amount of metal elements in the active component of the catalyst is 3.0% (based on the catalyst). The X-ray diffraction spectrum of the obtained catalyst is as follows figure 1 As shown, it can be seen from the spectrum that the catalyst is composed of spinel-structured ZnFe 2 o 4 , oxide ZnO and carrier Al 2 o 3 .

Embodiment 2

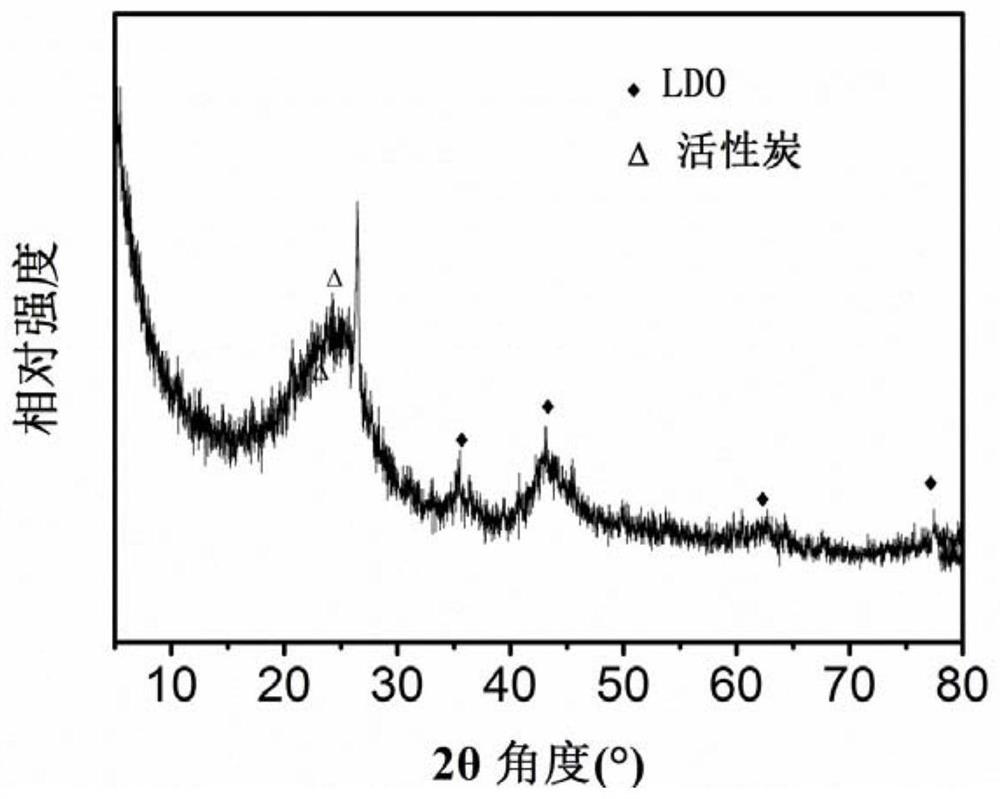

[0026] Analytical grade 1.98g FeCl 2 4H 2 O, 2.42g CoCl 2 ·6H 2 O, 1.32g MoCl 5 Dissolve in 20mL of deionized water, add 5.6g of activated carbon powder to the resulting mixed salt solution, then pass through oxygen and stir, while adding dropwise 3% sodium hydroxide aqueous solution and 6% sodium bicarbonate The mass ratio of the aqueous solution is a mixed solution of 1:1, the pH of the solution is controlled to be 9.7, and the reaction is carried out at 100°C for 8 hours, then suction-filtered and dried at 120°C for 12 hours, and then roasted at 350°C for 2 hours to obtain activated carbon-loaded containing The Fe(III)-based catalyst of Co(II) and Mo(VI), the loading amount of metal elements in the catalyst active component is 26.4% (calculated as catalyst). The X-ray diffraction spectrum of the obtained catalyst is as follows figure 2 It can be seen from the spectrogram that the catalyst is composed of Co(II), Mo(VI) and Fe(III) layered double metal oxides (LDO) and ...

Embodiment 3

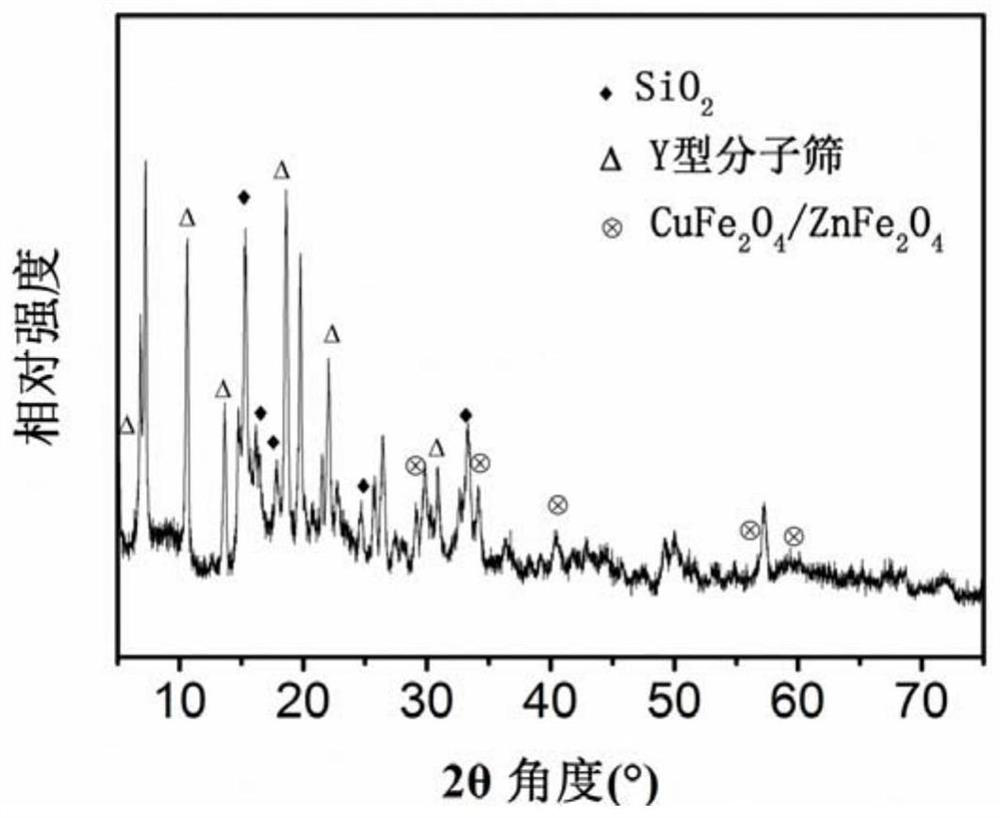

[0028] 22g of analytical grade (NH 4 ) 2 Fe(SO 4 ) 2 ·6H 2 O, 14g Cu(SO 4 ) 2 ·5H 2 O, 17g ZnSO 4 ·7H 2 O was dissolved in 500 mL of deionized water, and 100 g of SiO was added to the resulting mixed salt solution 2 Mixed powder with Y-type molecular sieve (where SiO 2 The mass ratio with Y-type molecular sieve is 1:2), then feed into the air and stir, while adding dropwise the mass fraction of 3% potassium acetate aqueous solution and the mass fraction of 6% potassium hydroxide aqueous solution, the mass ratio is 1:1 Control the pH of the solution to be 8.0, react at 60°C for 2 hours, then suction filter and dry at 100°C for 12h, after drying, bake at 500°C for 4h to obtain SiO 2 With the Fe(III)-based catalyst containing Cu(II) and Zn(II) supported by Y-type molecular sieve, the loading amount of metal elements in the catalyst active component is 11.3% (calculated as catalyst). The X-ray diffraction spectrum of the obtained catalyst is as follows image 3 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com