Synthetic polyisoprene latex

A technology of polyisoprene and isoprene, which is applied in the direction of synthetic resin layered products, conjugated diene adhesives, adhesives, etc., and can solve problems such as poor film-forming properties and reduced tensile strength of impregnated moldings , to achieve excellent film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

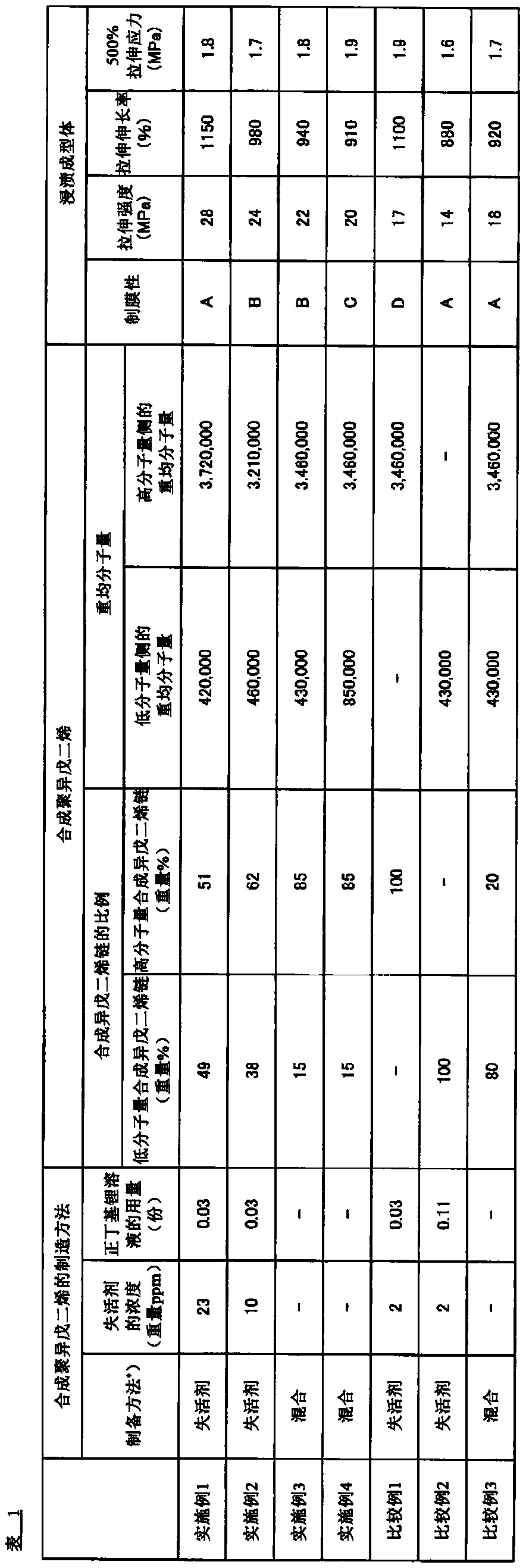

Examples

preparation example Construction

[0089] The method for preparing the latex composition of the present invention is not particularly limited, and examples thereof include mixing a crosslinking agent with a synthetic polyisoprene latex using a dispersing machine such as a ball mill, a kneader, and a disperser, and various compounds compounded as necessary. The method of compounding ingredients; using the above-mentioned disperser to prepare an aqueous dispersion of compounding components other than synthetic polyisoprene latex, and then mixing the aqueous dispersion with synthetic polyisoprene latex, etc.

[0090] The latex composition of the present invention preferably has a pH of 7 or more, more preferably has a pH in the range of 7-13, and still more preferably has a pH in the range of 8-12. In addition, the solid content concentration of the latex composition is preferably in the range of 15 to 65% by weight.

[0091] The latex composition of the present invention is preferably aged (pre-crosslinked) befor...

Embodiment

[0110] Hereinafter, the present invention will be described in detail through examples, but the present invention is not limited by these examples. In addition, the following "parts" are based on weight unless otherwise specified. In addition, various physical properties were measured as follows.

[0111] Molecular weight distribution curve, weight average molecular weight (Mw)

[0112] The sample was diluted with tetrahydrofuran so that the solid content concentration became 0.1% by weight, and the solution was analyzed by gel permeation chromatography in terms of standard styrene to obtain a molecular weight distribution curve, and the weight average molecular weight (Mw) was calculated.

[0113] Solid content concentration

[0114] Accurately weigh 2 g of the sample into an aluminum dish (weight: X1) (weight: X2), and dry it in a hot air drier at 105° C. for 2 hours. Next, after cooling in a desiccator, the weight was measured together with the aluminum dish (weight:...

manufacture example 1

[0124] Production example 1 (production of n-hexane solution of synthetic polyisoprene (A-1))

[0125] Add 1150 parts of n-hexane (i.e., n-hexane containing 23 wt. alkane), and 100 parts of isoprene. Next, the temperature in the autoclave was set at 60° C., and 0.03 parts of a hexane solution having a concentration of n-butyllithium of 15% by weight was added with stirring, and reacted for 1 hour. The polymerization reaction rate was 99%. To the obtained polymer solution, 0.05 part of methanol was added as a polymerization terminator to terminate the reaction to obtain a n-hexane solution of synthetic polyisoprene (A-1). Then, the molecular weight distribution curve of the synthetic polyisoprene (A-1) in the n-hexane solution was measured according to the above-mentioned method. As a result, the molecular weight distribution curve was bimodal (the poles on the side of the low-molecular-weight synthetic isoprene chain could be confirmed). The two maximum points are the lar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com