A method for preparing nickel-cobalt-manganese ternary cathode material precursor with manganese nodules

A cathode material, a technology of manganese nodules, applied in the field of nickel-cobalt-manganese ternary cathode material preparation, to achieve the effect of reducing environmental pollution, completely separating, and breaking through resource bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] This embodiment includes the following steps:

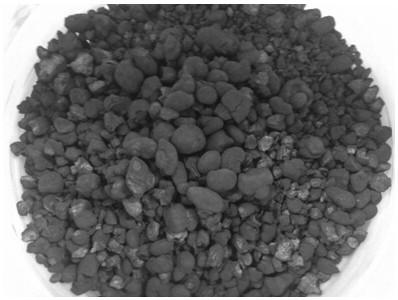

[0068] 1.1 Take 1kg of manganese nodules, crush them to -60 mesh, dry them to a moisture content of 5.1wt%, mix the crushed and dried manganese nodules, coke, quartz, and quicklime to obtain a mixed material; , of which coke accounts for 10%, quartz accounts for 3%, quicklime accounts for 4%, and manganese nodules after crushing and drying account for 83%; CaO in quicklime / SiO in quartz 2 Mass ratio<1.5;

[0069] 1.2 The mixed material obtained in step (1) was reduced and smelted at 1300°C for 30 minutes to obtain molten alloys of nickel, cobalt, manganese, iron, and copper (a small amount), and the slag was discarded; the alloy yield was 10.86%, and the raw material Manganese nodules and the alloy composition obtained in this step are (wt%):

[0070]

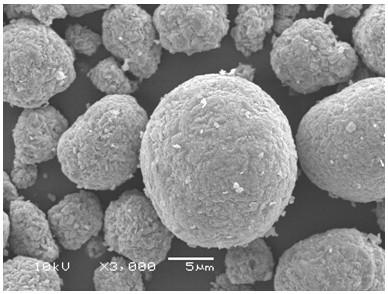

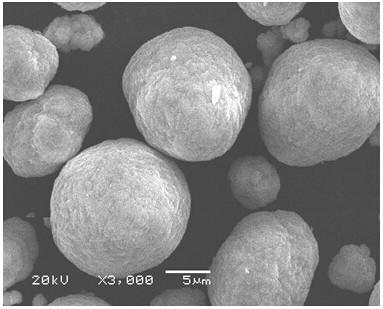

[0071] 1.3 Add the molten alloy of nickel, cobalt, manganese, iron and copper obtained in step (2) into the atomization powder making device, and spray powder with hig...

Embodiment 2

[0091] This embodiment includes the following steps:

[0092] 2.1 Take 1kg of manganese nodules, crush them to -60 mesh, dry them to a moisture content of 9.8wt%, mix the crushed and dried manganese nodules, coke, quartz, and quicklime to obtain a mixed material; in the mixed material, by mass percentage, Among them, coke accounts for 8%, quartz accounts for 5%, quicklime accounts for 6%, and the rest is broken and dried manganese nodules, CaO in quicklime / SiO in quartz 2 Mass ratio<1.5;

[0093] 2.2 The mixed material obtained in step (1) was reduced and smelted at 1400°C for 90 minutes to obtain alloys of nickel, cobalt, manganese, iron, and copper (a small amount) in molten state, and the slag was discarded; the yield of the alloy was 11.24%, and the manganese The composition of the nodules and the resulting alloy is (wt%):

[0094]

[0095] 2.3 Add the molten alloy of nickel, cobalt, manganese, iron and copper obtained in step (2) into the atomization powder making de...

Embodiment 3

[0115] This embodiment includes the following steps:

[0116] 3.1 Take 1kg of manganese nodules, crush them to -80 mesh, dry them to a moisture content of 9.8wt%, mix the crushed and dried manganese nodules, coke, quartz, and quicklime to obtain a mixed material; in the mixed material, by mass percentage, Among them, coke accounts for 8%, quartz accounts for 5%, quicklime accounts for 6%, and the rest is broken and dried manganese nodules; CaO in quicklime / SiO in quartz 2 Mass ratio<1.5;

[0117] 3.2 The mixed material obtained in step (1) was reduced and smelted at 1600°C for 120 minutes to obtain molten alloys of nickel, cobalt, manganese, iron, and copper (a small amount), and the slag was discarded; the alloy yield was 11.56%, and the manganese The composition of nodules and the resulting alloy is (%):

[0118]

[0119] 3.3 Add the molten alloy of nickel, cobalt, manganese, iron and copper obtained in step (2) into the atomization powder making device, and spray powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com