Tail gas after-treatment mixing device

A technology of exhaust after-treatment and mixing device, applied in exhaust treatment, exhaust device, mixer and other directions, can solve problems such as blockage of exhaust pipe, decrease in engine power performance, leakage of ammonia and ammonia, etc., to increase distance and time, improve Anti-crystallization ability, the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

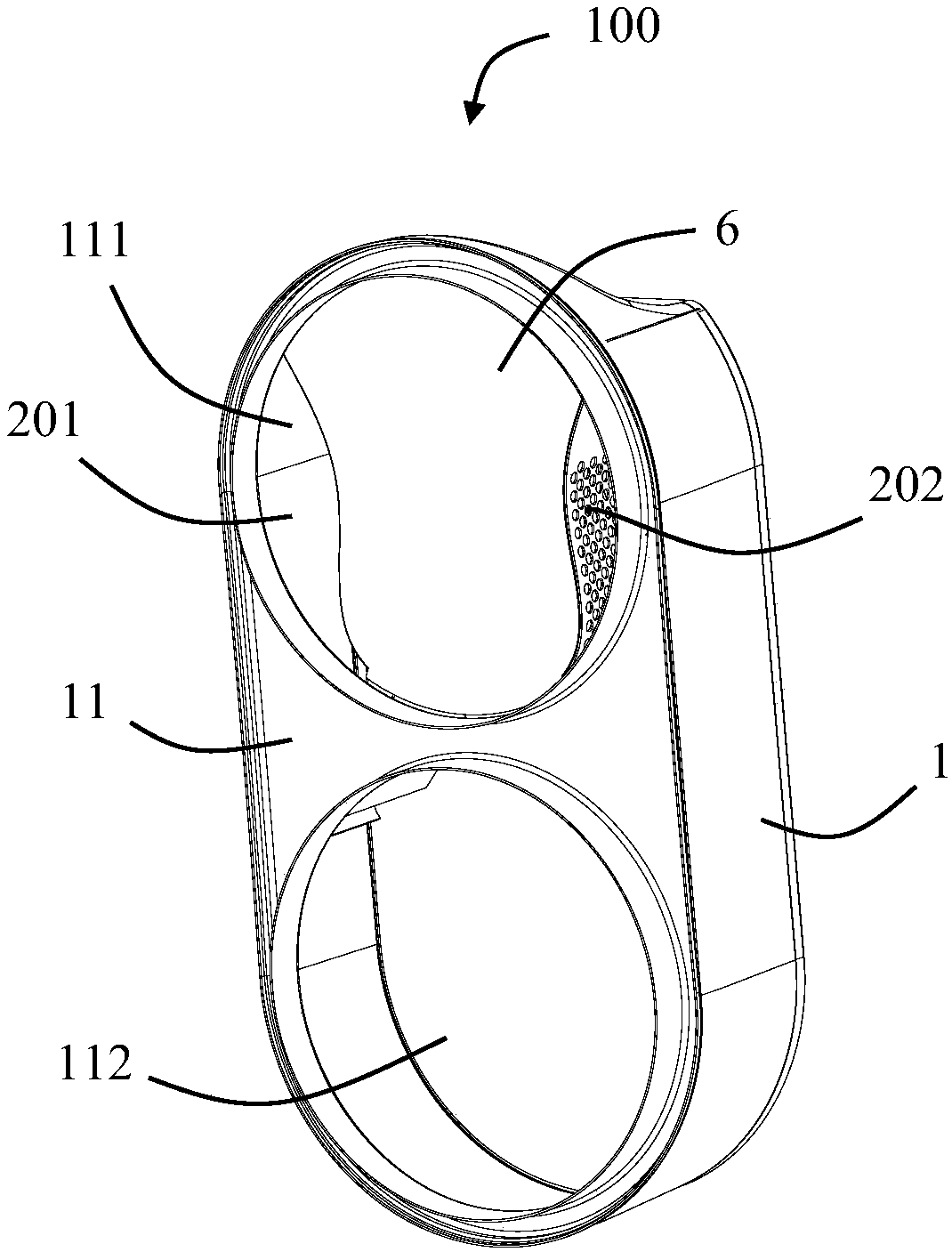

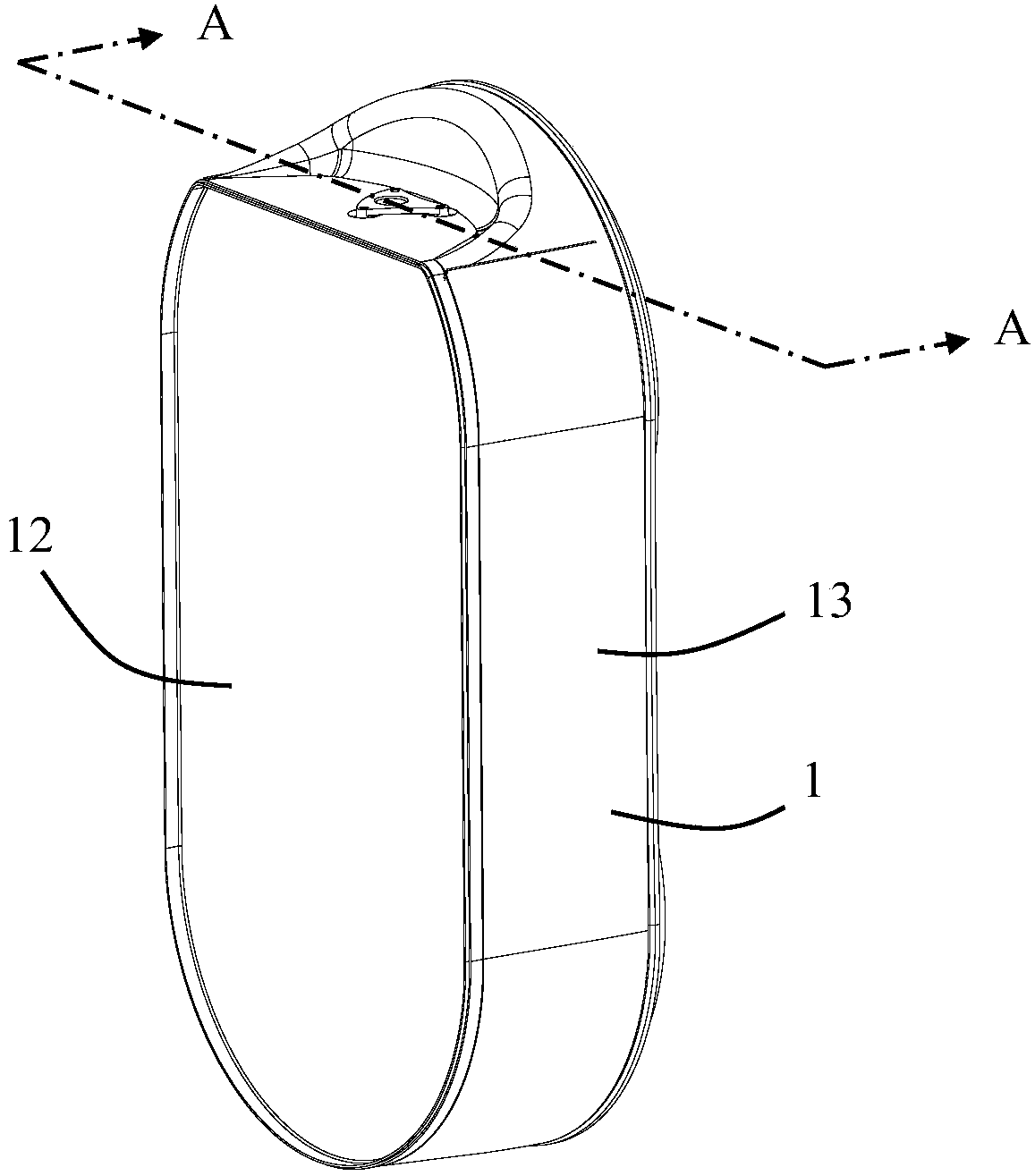

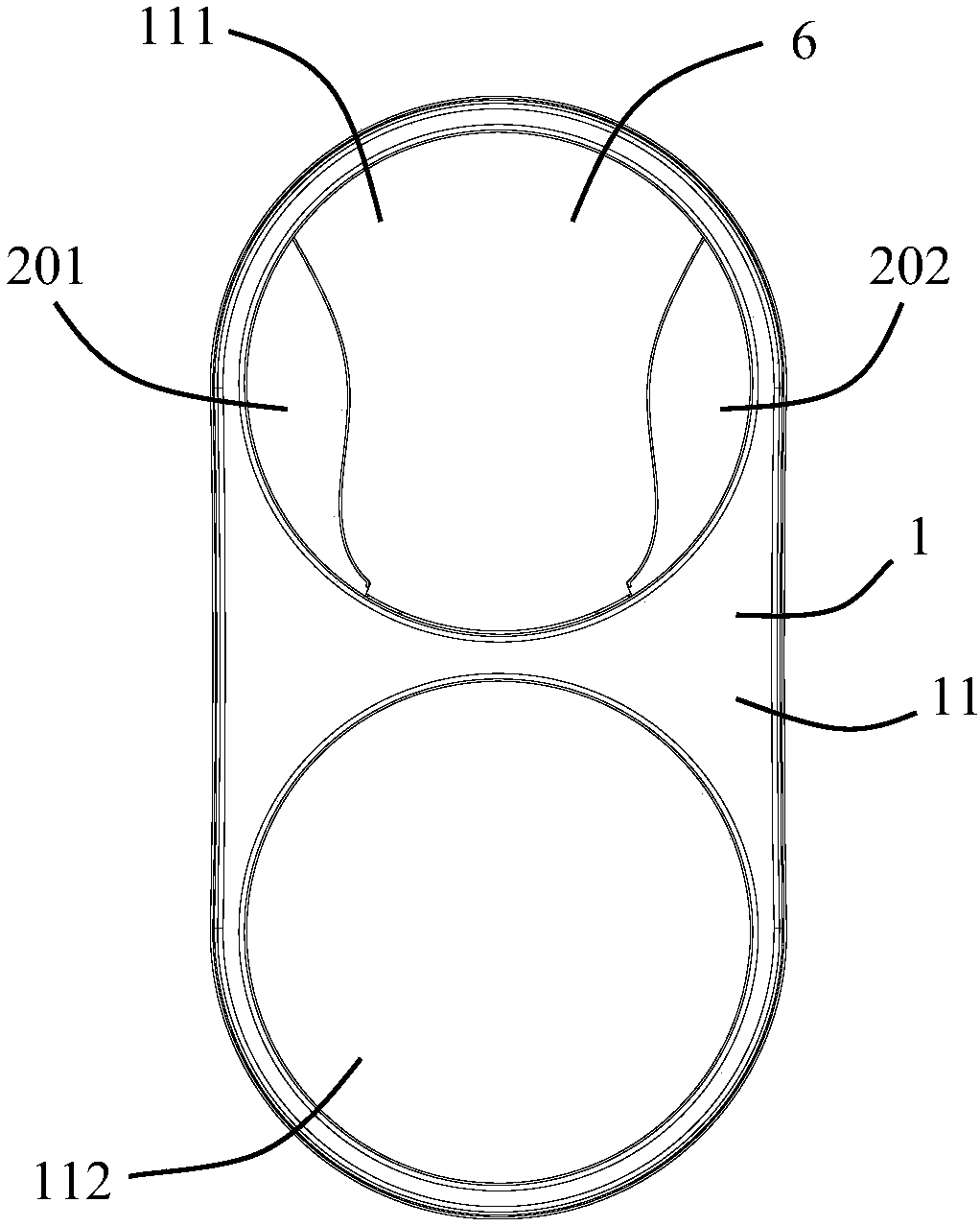

[0025] Please refer to Figure 1 to Figure 8 As shown, the present invention discloses an exhaust gas after-treatment mixing device 100 used in after-treatment systems such as SCR to treat engine exhaust. The exhaust gas post-treatment mixing device 100 includes a housing 1 and a mixing assembly 2 installed in the housing 1 .

[0026] In the illustrated embodiment of the present invention, the housing 1 is provided with a first baffle 11 , a second baffle 12 opposite to the first baffle 11 , and surrounding the first baffle 11 and the The casing 13 of the second baffle 12 . The first baffle 11 has a first opening 111 and a second opening 112 below the first opening 111 . The first opening 111 is used for air flow in, and the second opening 112 is used for air flow out. A mounting base 131 is welded on the top of the housing 13 . The installation seat 131 is used for installing a urea nozzle (not shown) to inject urea into the mixing assembly 2 .

[0027] The mixing assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com