A kind of atmospheric pressure dip-dyeing process of bio-based ptt series polyester fabric

A polyester fabric, bio-based technology, applied in the field of textile printing and dyeing, can solve the problems of high energy consumption, low dye uptake, low affinity of polyester fiber fabrics, etc., and achieve the effects of reducing emissions, easy operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

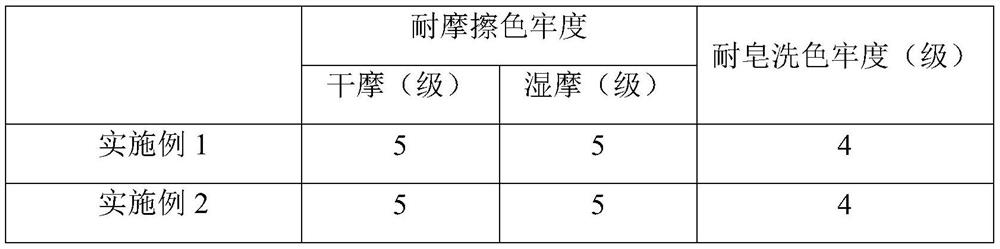

Embodiment 1

[0029] (1) One-bath treatment for desizing and cleaning: use sodium lauryl sulfate, polyoxyethylene ether compound detergent (1:1 compound, 5g / L in total), sodium hydroxide (3g / L) to remove The size of the bio-based PTT polyester fabric and the oily stains on the fabric were then dried at 40°C.

[0030] (2) Presetting: dry heat setting, the temperature is 130°C, the time is 60s, and the pretension is 1%.

[0031] (3) Alkali treatment: Exhaust dyeing, liquor ratio 1:40, lye concentration 10g / L, treatment temperature 95°C, treatment time 30min.

[0032] (4) Preparation of dye solution: madder dye content 2% (o.w.f), with CH 3 COOH-CH 3 COONa buffer was used to adjust the pH value of the dye bath to 5, and ultrasonic treatment was performed for 20 min.

[0033] (5) The dyeing bath is first heated from room temperature to 50°C, and the fabric is put into the prepared dye solution, the heating rate is 2°C / min, the holding temperature is 95°C, and the holding time is 30 minutes. ...

Embodiment 2

[0035] (1) One-bath treatment for desizing and cleaning: use sodium lauryl sulfate, polyoxyethylene ether compound detergent (1:1 compound, 5g / L in total), sodium hydroxide (3g / L) to remove The size of the bio-based PTT / PET composite fabric during weaving and the oily stains on the fabric were then dried at 40°C.

[0036] (2) Presetting: dry heat setting, the temperature is 140°C, the time is 60s, and there is no pretension.

[0037] (3) Alkali treatment: Exhaust dyeing, liquor ratio 1:40, lye concentration 10g / L, treatment temperature 95°C, treatment time 30min.

[0038] (4) Preparation of dye solution: madder dye content 2% (o.w.f), with CH 3 COOH-CH 3 COONa buffer was used to adjust the pH value of the dye bath to 5, and ultrasonic treatment was performed for 20 min.

[0039] (5) The dyeing bath is first heated from room temperature to 50°C, and the fabric is put into the prepared dye solution. The heating rate is 2°C / min, the holding temperature is 95°C, and the holding...

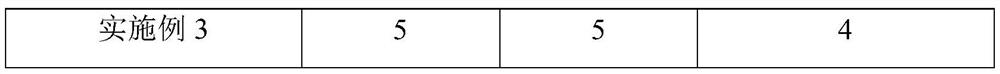

Embodiment 3

[0041] (1) One-bath treatment for desizing and cleaning: use sodium lauryl sulfate, polyoxyethylene ether compound detergent (1:1 compound, 5g / L in total), sodium hydroxide (3g / L) to remove The size of the bio-based PTT / modified PET composite fabric during weaving and the oily stains on the fabric were then dried at 40°C.

[0042] (2) Presetting: dry heat setting, the temperature is 130°C, the time is 60s, and the pretension is 1%.

[0043](3) Alkali treatment: Exhaust dyeing, bath ratio 1:40, lye concentration 15g / L, treatment temperature 95°C, treatment time 30min.

[0044] (4) Preparation of dye solution: madder dye content 2% (o.w.f), with CH 3 COOH-CH 3 COONa buffer was used to adjust the pH value of the dye bath to 5, and ultrasonic treatment was performed for 20 min.

[0045] (5) The dyeing bath is first heated from room temperature to 50°C, and the fabric is put into the prepared dye solution, the heating rate is 2°C / min, the holding temperature is 95°C, and the hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com