Fluorine-free water-repellent finishing method for polyester fabric

A fluorine-free water-repellent technology for polyester fabrics, applied in physical treatment, fiber treatment, textiles and papermaking, etc., can solve the problems of poor water-repellent effect and long finishing time, and achieve reduced finishing time, high washing fastness, The effect of water repellent effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Wash the polyester fabric with ethyl acetate at room temperature and dry it at 50°C for use, then treat it in 300g / L concentrated alkali solution at room temperature for 10 minutes, take it out and cover it with polyethylene film, then transfer it to an oven at 120°C for 3 minutes . Then use 8g / L acetic acid solution to remove residual lye and then rinse with a large amount of deionized water until the surface of the fabric is neutral, and finally bake it in a 50°C oven until dry to obtain a pretreated polyester fabric.

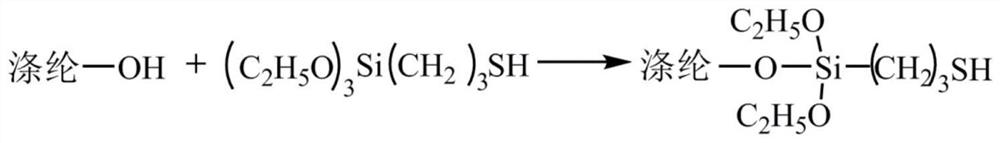

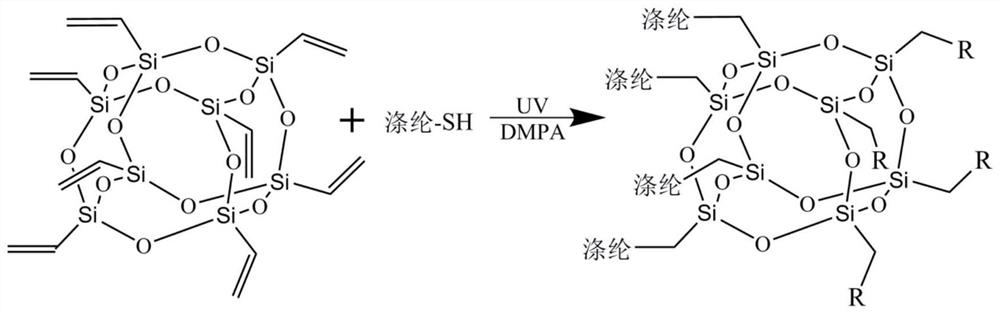

[0042] (2) prepare 3wt% 3-mercaptopropyl triethoxysilane ethyl acetate solution, adopt solution dipping method to carry out mercapto group modification, the pretreatment polyester fabric that step (1) obtains is dropped in the solution, beaker mouth film sealing , placed in a constant temperature magnetic stirring water bath, 25 ° C shock treatment for 2 hours, the polyester fabric was taken out, fully washed in distilled water, and vacuum-dried at...

Embodiment 2

[0047] (1) Wash the polyester fabric with ethyl acetate at room temperature and dry it at 50°C for use, then treat it in a 360g / L concentrated alkali solution at room temperature for 10 minutes, take it out and cover it with polyethylene film, then transfer it to an oven at 120°C for 3 minutes . Then use 10g / L acetic acid solution to remove residual lye and then rinse with a large amount of deionized water until the surface of the fabric is neutral, and finally bake it in a 50°C oven until dry to obtain a pretreated polyester fabric.

[0048] (2) Prepare 5wt% 3-mercaptopropyltriethoxysilane ethyl acetate solution, adopt solution dipping method to carry out mercapto modification, put the pretreated polyester fabric obtained in step (1) into the solution, and seal the beaker mouth film , placed in a constant temperature magnetic stirring water bath, 25 ° C shock treatment for 2 hours, the polyester fabric was taken out, fully washed in distilled water, and vacuum-dried at 60 ° C...

Embodiment 3

[0052] (1) Wash the polyester fabric with ethyl acetate at room temperature and dry it at 50°C for use, then treat it in 300g / L concentrated alkali solution at room temperature for 10 minutes, take it out and cover it with polyethylene film, then transfer it to an oven at 120°C for 3 minutes . Then use 3g / L acetic acid solution to remove residual lye and then rinse with a large amount of deionized water until the surface of the fabric is neutral, and finally bake it in a 50°C oven until dry to obtain a pretreated polyester fabric.

[0053] (2) prepare 3wt% 3-mercaptopropyl triethoxysilane ethyl acetate solution, adopt solution dipping method to carry out mercapto group modification, the pretreatment polyester fabric that step (1) obtains is dropped in the solution, beaker mouth film sealing , placed in a constant temperature magnetic stirring water bath, 25 ° C shock treatment for 2 hours, the polyester fabric was taken out, fully washed in distilled water, and vacuum-dried at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com