A kind of preparation method of manganese steel material in double grain structure

A technology of grain structure and manganese steel, applied in the field of metallurgy, can solve the problems affecting the anti-intrusion performance and low yield strength of automobile components, and achieve the effect of maintaining continuous yield characteristics and improving yield strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

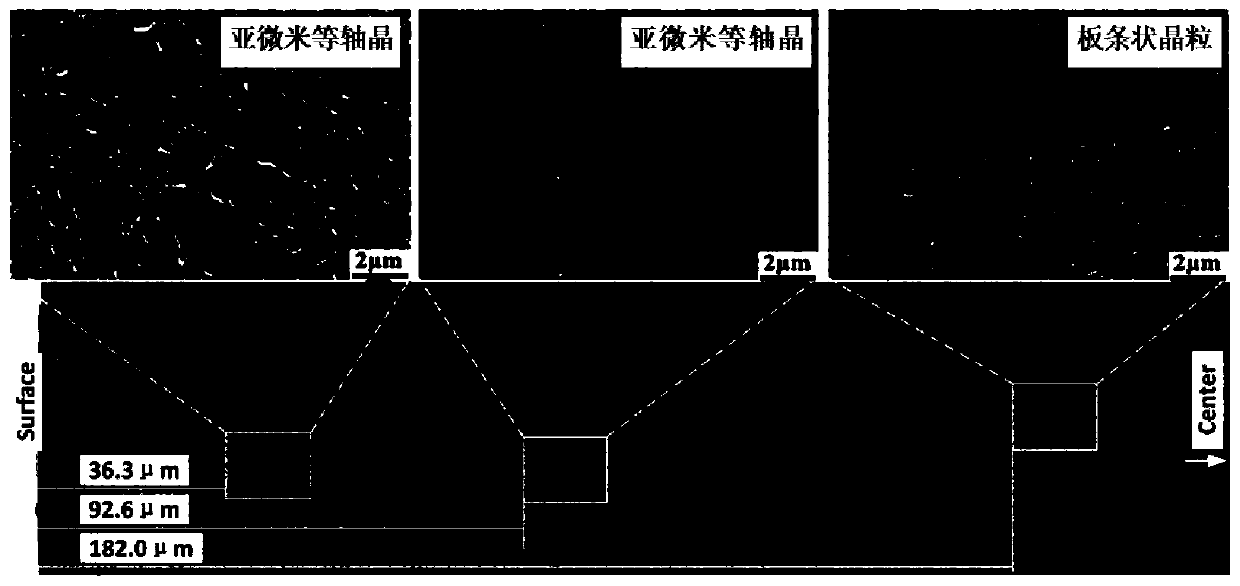

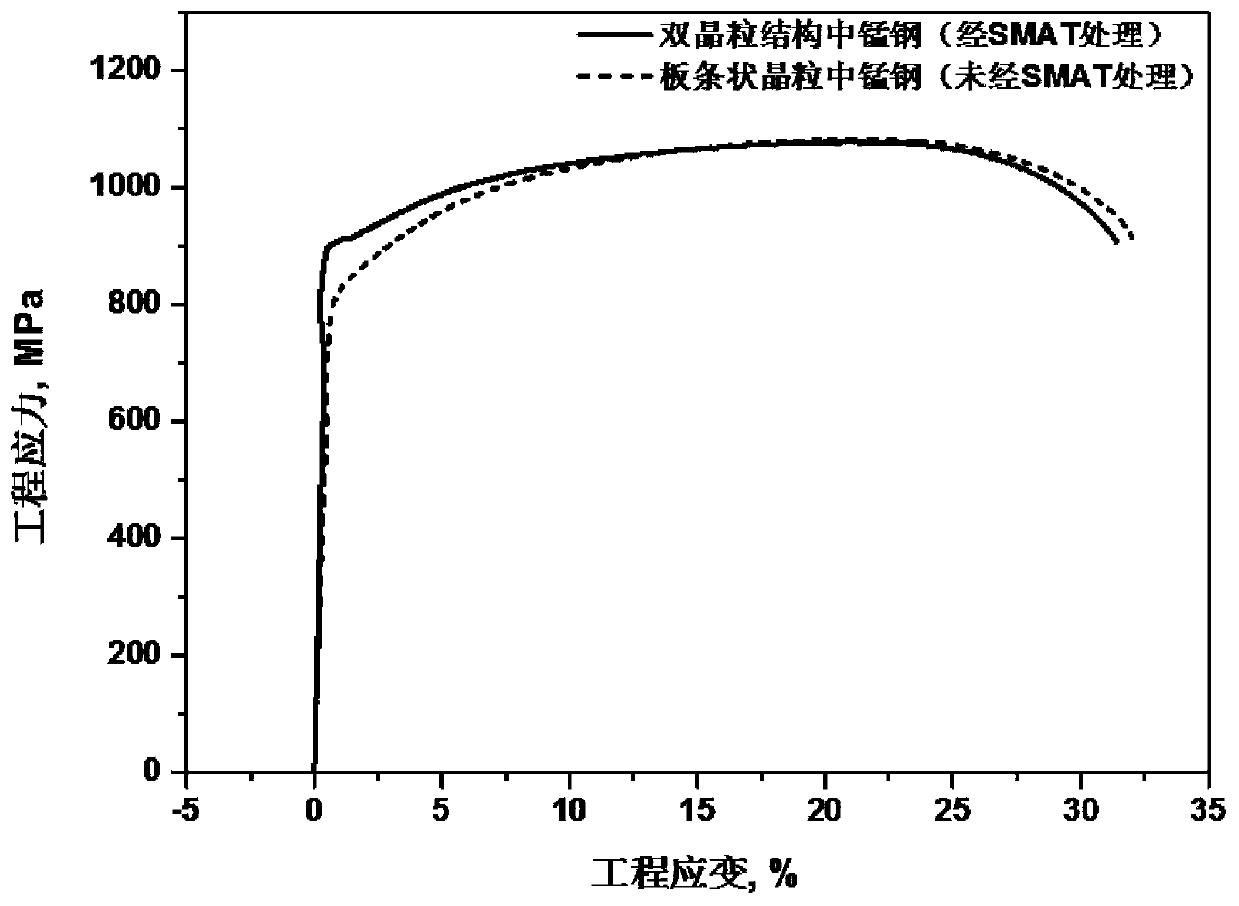

[0024] 1. Heat the cold-rolled medium manganese steel plate to 850°C for complete austenitization, and then quench it to room temperature at a cooling rate of 30°C / s to obtain a complete martensite structure.

[0025] 2. Perform surface mechanical grinding treatment (SMAT) on the quenched medium-manganese steel cold-rolled plate. SMAT treatment uses AISI304 stainless steel balls with a diameter of 5mm and a vibration frequency of 10kHz. The cumulative processing time of SMAT on one side of the steel plate was set at 30 minutes. In order to avoid warping of the steel plate caused by mechanical grinding on one side for a long time, the designed treatment time on one side is 10 minutes, then turn the steel plate over and continue to process the other surface, and ensure that the SMAT treatment time on both sides of the steel plate is the same.

[0026] 3. Perform ART annealing on the medium-manganese steel plate after SMAT treatment. The annealing temperature is 650°C, the holdi...

Embodiment 2

[0031] 1. Heat the cold-rolled medium manganese steel plate to 900°C for complete austenitization, and then quench it to room temperature at a cooling rate of 50°C / s to obtain a complete martensite structure.

[0032] 2. Perform surface mechanical grinding treatment (SMAT) on the quenched medium-manganese steel cold-rolled plate. SMAT treatment uses AISI304 stainless steel balls with a diameter of 3mm and a vibration frequency of 30kHz. The cumulative processing time of SMAT on one side of the steel plate is set at 60 minutes. In order to avoid warping of the steel plate caused by mechanical grinding on one side for a long time, the designed treatment time on one side is 10 minutes, then turn the steel plate over and continue to process the other surface, and ensure that the SMAT treatment time on both sides of the steel plate is the same.

[0033] 3. Perform ART annealing on the medium-manganese steel plate after SMAT treatment. The annealing temperature is 700°C, the holdin...

Embodiment 3

[0038] 1. Heat the cold-rolled medium manganese steel plate to 950°C for complete austenitization, and then quench it to room temperature at a cooling rate of 20°C / s to obtain a complete martensite structure.

[0039] 2. Perform surface mechanical grinding treatment (SMAT) on the quenched medium-manganese steel cold-rolled plate. SMAT treatment uses AISI304 stainless steel balls with a diameter of 7mm and a vibration frequency of 20kHz. The cumulative processing time of SMAT on one side of the steel plate is set at 20 minutes. In order to avoid warping of the steel plate caused by mechanical grinding on one side for a long time, the designed treatment time on one side is 10 minutes, then turn the steel plate over and continue to process the other surface, and ensure that the SMAT treatment time on both sides of the steel plate is the same.

[0040] 3. Perform ART annealing on the medium-manganese steel plate after SMAT treatment. The annealing temperature is 600°C, the holdin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com