Multi-layer structured heat conducting composite containing heat conducting film and preparation method of multi-layer structured heat conducting composite

A heat-conducting composite material and multi-layer structure technology, applied in the direction of heat exchange materials, chemical instruments and methods, lamination, etc., can solve the problem of small increase in thermal conductivity, unsatisfactory modification effect, strong interlayer force, etc. problem, to achieve the effect of improving horizontal thermal conductivity, excellent horizontal thermal conductivity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

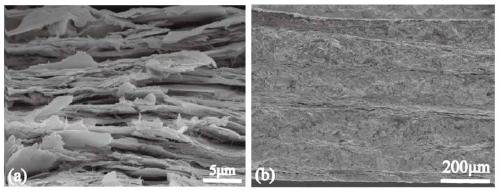

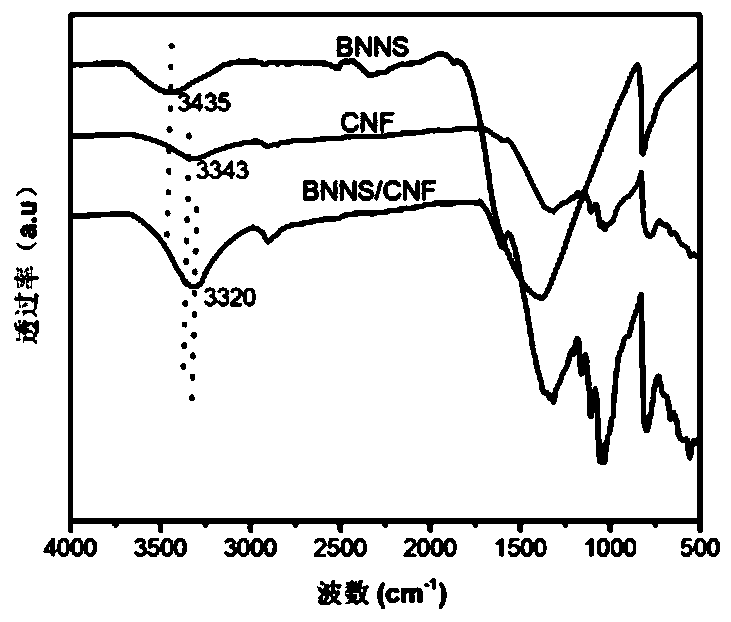

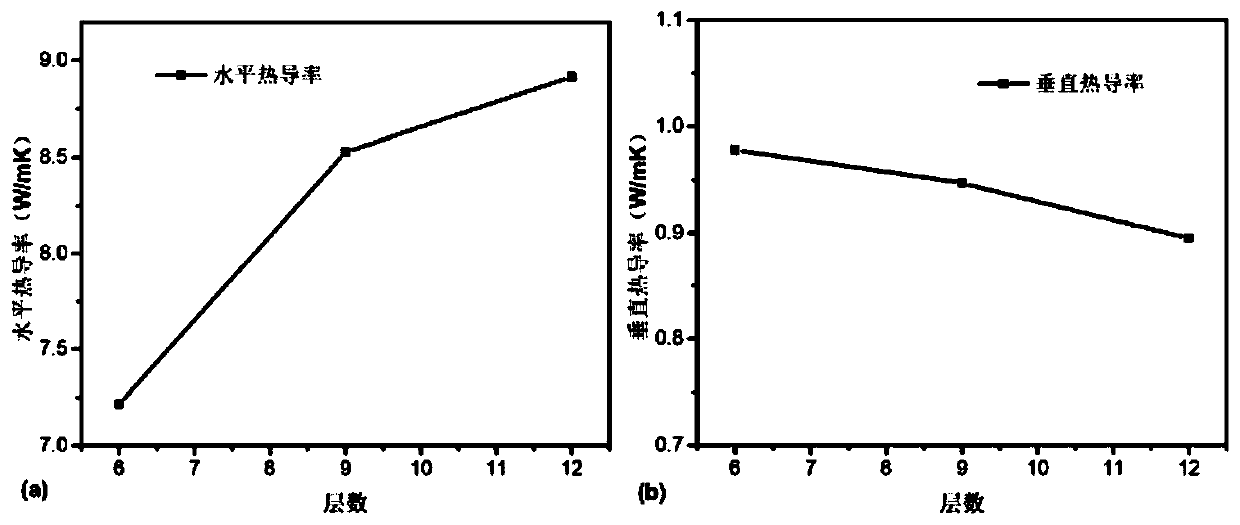

[0040] Using nanocellulose (CNF) as the matrix and hexagonal boron nitride as the thermally conductive filler, hexagonal boron nitride is subjected to liquid-phase ultrasonic exfoliation to obtain boron nitride nanosheets (BNNS), and then with the help of specific instruments, the method of shear-induced orientation is used. Preparation of boron nitride nanosheet / nanocellulose (BNNS / CNF) thermally conductive alignment film;

[0041] According to the ratio of 100:90:1, weigh 10g of epoxy resin, 9g of amine curing agent, and 0.1g of imidazole curing accelerator, put them in a constant temperature water bath, and stir at 45°C for 30 minutes;

[0042] According to the ratio of 1:1, weigh 4.1g of h-BN particles with a particle size of 25μm and 4.1g of AlN particles with a particle size of 1μm (that is, the filler content is 30wt%), and gradually add the two fillers to the above epoxy In the resin mixture, stirring was continued for 3 hours at 45°C;

[0043] Use a needle roller to me...

Embodiment 2

[0050] Using nanocellulose (CNF) as the matrix and hexagonal boron nitride as the thermally conductive filler, hexagonal boron nitride is subjected to liquid-phase ultrasonic exfoliation to obtain boron nitride nanosheets (BNNS), and then with the help of specific instruments, the method of shear-induced orientation is used. Preparation of boron nitride nanosheet / nanocellulose (BNNS / CNF) thermally conductive alignment film;

[0051] According to the ratio of 100:90:1, weigh 10g of epoxy resin, 9g of amine curing agent, and 0.1g of imidazole curing accelerator, put them in a constant temperature water bath, and stir at 45°C for 30 minutes;

[0052] According to the ratio of 1:1, weigh 4.1g of h-BN particles with a particle size of 25μm and 4.1g of AlN particles with a particle size of 1μm (that is, the filler content is 30wt%), and gradually add the two fillers to the above epoxy In the resin mixture, stirring was continued for 3 hours at 45°C;

[0053] Use a needle roller to ...

Embodiment 3

[0058] Using nanocellulose (CNF) as the matrix and hexagonal boron nitride as the thermally conductive filler, hexagonal boron nitride is subjected to liquid-phase ultrasonic exfoliation to obtain boron nitride nanosheets (BNNS), and then with the help of specific instruments, the method of shear-induced orientation is used. Preparation of boron nitride nanosheet / nanocellulose (BNNS / CNF) thermally conductive alignment film;

[0059] According to the ratio of 100:90:1, weigh 10g of epoxy resin, 9g of amine curing agent, and 0.1g of imidazole curing accelerator, put them in a constant temperature water bath, and stir at 45°C for 30 minutes;

[0060] According to the ratio of 1:1, weigh 4.1g of h-BN particles with a particle size of 25μm and 4.1g of AlN particles with a particle size of 1μm (that is, the filler content is 30wt%), and gradually add the two fillers to the above epoxy In the resin mixture, stirring was continued for 3 hours at 45°C;

[0061] Use a needle roller to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com