Green high-performance polymer cement waterproof mortar adopting aeolian sand and preparation method of waterproof mortar

A high-performance polymer, waterproof mortar technology, applied in the field of building waterproof materials, can solve problems such as scarcity of raw materials, and achieve the effects of improving mechanical properties and impermeability, saving resources, and achieving significant waterproofing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

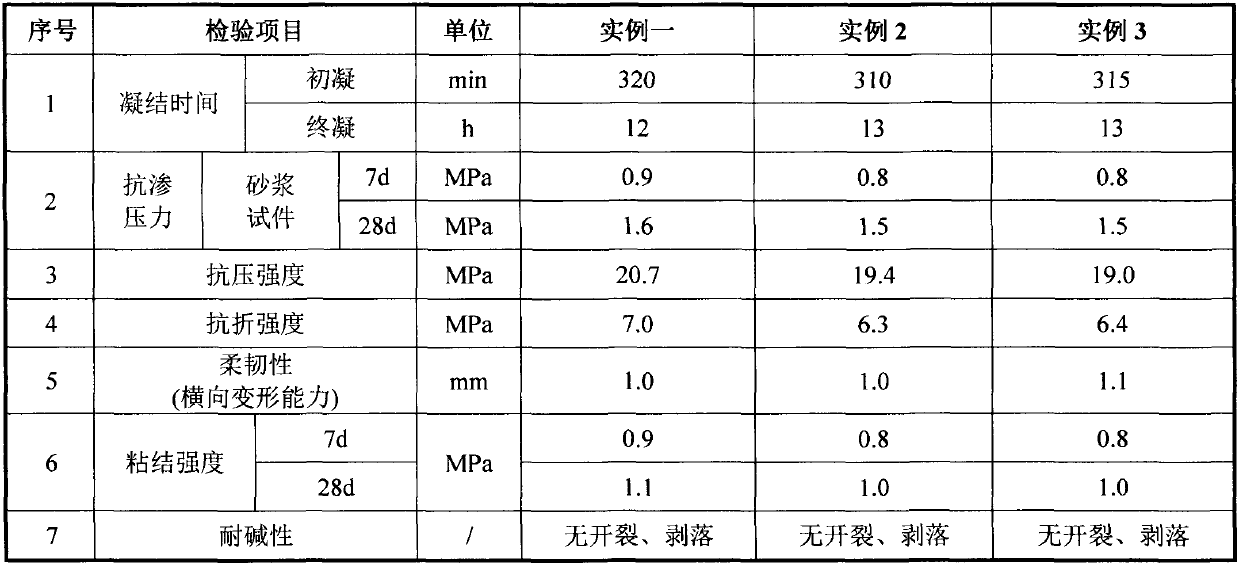

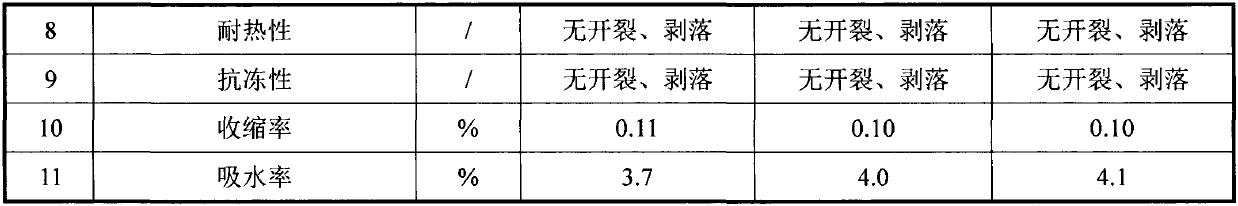

Examples

Embodiment 1

[0033] A green high-performance polymer cement waterproof mortar using aeolian sand, in parts by weight, including the following components:

[0034] PO·42.5 grade ordinary Portland cement 35%, quartz sand 30%, aeolian sand 25%, rubber powder 9%, polypropylene fiber 0.5%, water reducing agent 0.3%, defoaming agent 0.2%.

[0035] Preparation:

[0036] (1) Weigh the required materials, including: PO·42.5 grade ordinary Portland cement, quartz sand, aeolian sand, rubber powder, polypropylene fiber, water reducer and defoamer;

[0037] (2) Put the weighed PO·42.5 grade ordinary Portland cement, rubber powder, water reducing agent and defoamer into the Enrich-R three-dimensional mixer in turn, stir at low speed, and the rotor speed is 150 rpm , The rotating speed of the mixing disc is 40 revolutions per minute, and the mixing time is 100 minutes to obtain a uniform mixture M1;

[0038] (3) Add quartz sand and aeolian sand to the above-mentioned mixture M1, and stir at low speed, wherein the...

Embodiment 2

[0042] A green high-performance polymer cement waterproof mortar using aeolian sand, in parts by weight, including the following components:

[0043] PO·42.5 grade ordinary Portland cement 37%, quartz sand 28%, aeolian sand 26%, rubber powder 8%, polypropylene fiber 0.6%, water reducing agent 0.2%, defoaming agent 0.2%.

[0044] Preparation:

[0045] (1) Weigh the required materials, including: PO·42.5 grade ordinary Portland cement, quartz sand, aeolian sand, rubber powder, polypropylene fiber, water reducer and defoamer;

[0046] (2) Put the weighed PO·42.5 grade ordinary Portland cement, rubber powder, water reducing agent and defoamer into the Enrich-R three-dimensional mixer in turn, stir at low speed, and the rotor speed is 150 rpm , The rotating speed of the mixing disc is 40 revolutions per minute, and the mixing time is 100 minutes to obtain a uniform mixture M1;

[0047] (3) Add quartz sand and aeolian sand to the above-mentioned mixture M1, and stir at low speed, wherein the...

Embodiment 3

[0051] A green high-performance polymer cement waterproof mortar using aeolian sand, in parts by weight, including the following components:

[0052] PO·42.5 grade ordinary Portland cement 39%, quartz sand 28%, aeolian sand 26%, rubber powder 7%, polypropylene fiber 0.8%, water reducing agent 0.1%, defoaming agent 0.1%.

[0053] Preparation:

[0054] (1) Weigh the required materials, including: PO·42.5 grade ordinary Portland cement, quartz sand, aeolian sand, rubber powder, polypropylene fiber, water reducer and defoamer;

[0055] (2) Put the weighed PO·42.5 grade ordinary Portland cement, rubber powder, water reducing agent and defoamer into the Enrich-R three-dimensional mixer in turn, stir at low speed, and the rotor speed is 150 rpm , The rotating speed of the mixing disc is 40 revolutions per minute, and the mixing time is 100 minutes to obtain a uniform mixture M1;

[0056] (3) Add quartz sand and aeolian sand to the above-mentioned mixture M1, and stir at low speed, wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com