Microgel particle of bowl structure as well as preparation method and application of microgel particle

A technology of microgel particles and microgels, applied in chemical instruments and methods, colloid chemistry, colloid chemistry and other directions, can solve the problems of complex process, complex and tedious synthesis steps and processes, and not simple enough, so as to improve the adhesion ability, The effect of structure and performance tunable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

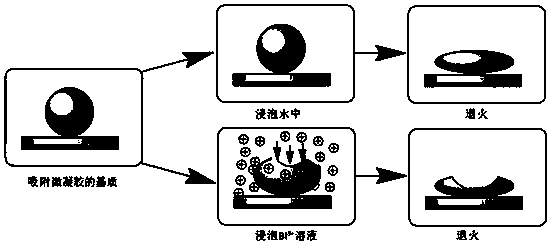

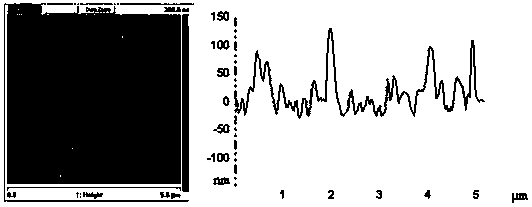

[0041] (1) According to the formula in Table 1, the monomer N-isopropylacrylamide (M 1 ), Acrylic (M 2 ), crosslinking agent N,N'-methylenebisacrylamide (M 3 ) was dissolved in water, and potassium persulfate was used as an initiator to obtain a dispersion solution of microgel particles through emulsion polymerization at 70° C., and dialyzed in deionized water to remove unreacted monomers and other water-soluble small molecules; the obtained microgel The particle size of the particles is 520nm;

[0042] (2) Soak the gold-plated glass piece in polyethyleneimine (M w =25 000, the solution concentration is 2mg L -1 ) in an aqueous solution for 5 minutes, self-assembled and adsorbed a polyethyleneimine layer, and dried with nitrogen; then soaked the polyethyleneimine-modified matrix into the microgel particle dispersion (0.02mg mL -1 ) for 5 minutes, the microgel particles are adsorbed to the surface of the matrix through electrostatic interaction and hydrogen bond interaction...

Embodiment 2

[0046] (1) According to the formula in Table 1, the monomer N-hydroxyethylacrylamide (M 1 ), methacrylic acid (M 2 ), crosslinking agent N,N'-ethylenediylbisacrylamide (M 3 ) was dissolved in water, and potassium persulfate was used as an initiator to obtain a dispersion solution of microgel particles through emulsion polymerization at 70° C., and dialyzed in deionized water to remove unreacted monomers and other water-soluble small molecules; the obtained microgel The particle size of the particles is 405nm;

[0047] (2) Soak the silicon wafer in polyethyleneimine (M w =25 000, the solution concentration is 2mg L -1 ) in an aqueous solution for 5 minutes, self-assembled and adsorbed a polyethyleneimine layer, and dried with nitrogen; then soaked the polyethyleneimine-modified matrix into the microgel particle dispersion (0.04mg mL -1 ) for 5 minutes, the microgel particles are adsorbed to the surface of the matrix through electrostatic interaction and hydrogen bond intera...

Embodiment 3

[0050] (1) According to the formula in Table 1, the monomer N-(methylol)acrylamide (M 1 ), 2-acrylamide-2-methylpropanesulfonic acid (M 2 ), crosslinking agent N,N'-methylenebisacrylamide (M 3 ) was dissolved in water, and potassium persulfate was used as an initiator to obtain a dispersion solution of microgel particles through emulsion polymerization at 70° C., and dialyzed in deionized water to remove unreacted monomers and other water-soluble small molecules; the obtained microgel The particle size of the particles is 290nm;

[0051] (2) Soak the glass piece in polyethyleneimine (M w =25 000, the solution concentration is 2mg L -1 ) in an aqueous solution for 5 minutes, self-assembled and adsorbed a polyethyleneimine layer, and dried with nitrogen; then soaked the polyethyleneimine-modified matrix into the microgel particle dispersion (0.06mg mL -1 ) for 5 minutes, the microgel particles are adsorbed to the surface of the matrix through electrostatic interaction and hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com