Engine bin built-in type fire extinguishing device

A fire extinguishing device and engine technology, which is applied in the direction of engine components, valve devices, valve operation/release devices, etc., can solve the problems of personal safety hazards of fire extinguishers, threats to the safety of operators, and inability to effectively extinguish fires, so as to protect personal safety and Property safety, reduce the loss of personnel and property, and prolong the effect of valuable time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

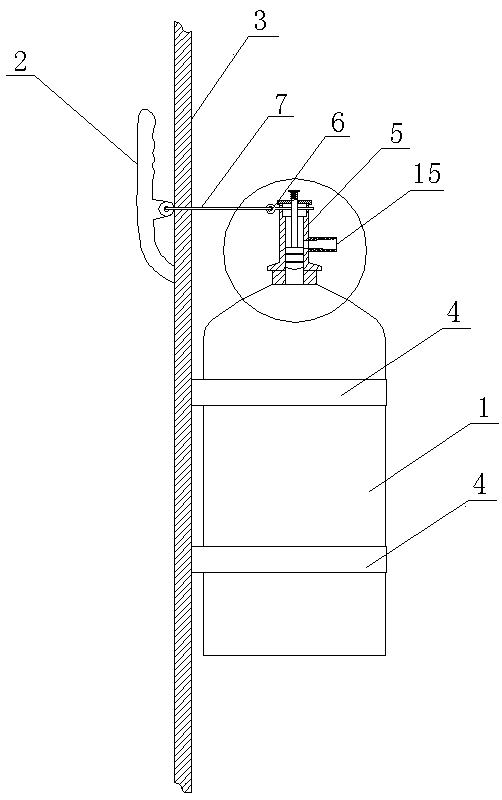

[0014] Such as figure 1 As shown, the engine compartment built-in fire extinguishing device of the present invention is made of the fire extinguisher steel cylinder 1 in the engine compartment and the fire extinguisher starting handle 2 in the driver's compartment. The fire extinguisher cylinder 1 in the engine compartment is fastened on the compartment wall 3 by a strap 4, and a start handle 2 is arranged in the driving compartment; the lock valve pin 6 of the fire extinguisher valve 5 of the fire extinguisher cylinder 1 passes through the compartment wall 3 and is set through a pull wire 7 The fire extinguisher starting handle 2 in the cab is connected.

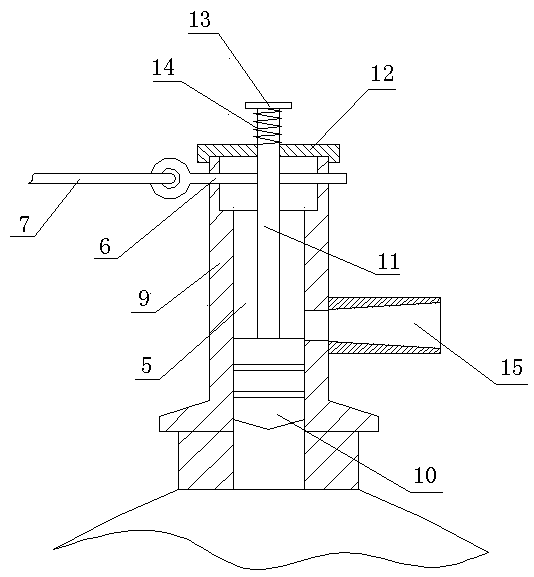

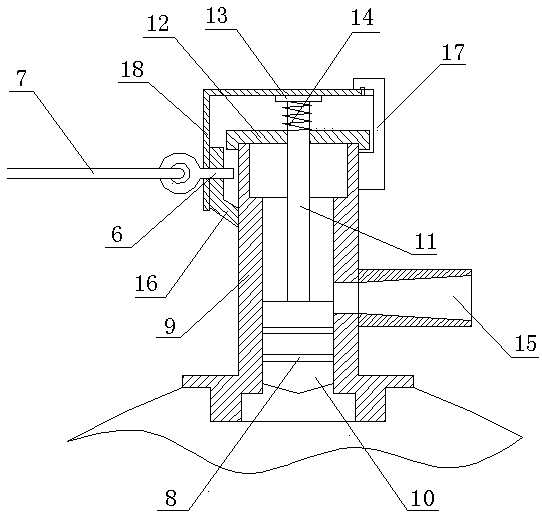

[0015] A fire extinguisher valve 5 is installed on the top of the fire extinguisher steel cylinder 1. The cylindrical valve body 9 of the valve is provided with a trumpet-shaped nozzle 15, and the valve plug 10 is fitted with a gap in the valve body 9, and a sealing ring is set on the valve plug 10 at intervals. The upper ...

Embodiment 2

[0018] Such as figure 1 As shown, the engine compartment built-in fire extinguishing device of the present invention is made of the fire extinguisher steel cylinder 1 in the engine compartment and the fire extinguisher starting handle 2 in the driver's compartment. A fire extinguisher is fixed in the engine compartment, and the fire extinguisher cylinder 1 is fastened to the compartment wall 3 by a strap 4. The locking valve pin 6 of the fire extinguisher valve 5 of the fire extinguisher cylinder 1 passes through the compartment wall 3 and the fire extinguisher arranged in the driving compartment through a pull wire 7 The starter handle 2 is connected.

[0019] In this fire extinguishing device, a fire extinguisher valve 5 is installed on the top of the fire extinguisher steel cylinder 1, and a trumpet-shaped nozzle 15 is arranged on the cylindrical valve body 9 of the valve, and a valve plug 10 is matched in the gap between the cylindrical valve body 9, and the valve plug 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com