Air-regulation cultivation method for green bean sprouts and device of method

A cultivation method and technology of bean sprouts, applied in cultivation, soilless cultivation, gardening methods, etc., can solve problems such as safety, harm to human health and life safety, hidden dangers, etc., achieve uniform length, ensure quality and yield, and nutritional content The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment one: the modified atmosphere method of the present invention produces bean sprouts

[0054] The invention provides a method for the controlled atmosphere cultivation of mung bean sprouts, comprising the steps of:

[0055] (1) First, the raw beans are strictly screened to remove bad beans and germ-free beans.

[0056] (2) Blanch the beans, put the screened beans into hot water for 1 to 2 minutes, and stir.

[0057] (3) Soak the beans, soak the screened beans in warm water for 90 to 150 minutes.

[0058] (4) After soaking the beans, drain the water and spread the beans evenly in the incubator. The incubator is sterilized by high temperature or sprayed with 100PPM sodium hypochlorite.

[0059] (5) Move the incubator into the aseptic cultivation room to carry out the controlled atmosphere cultivation system of sprouts, the temperature is controlled at 22°C to 24°C, and water is sprayed periodically.

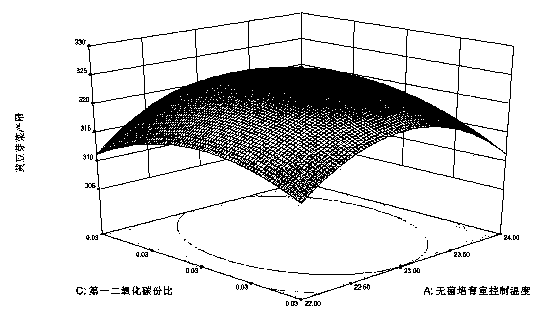

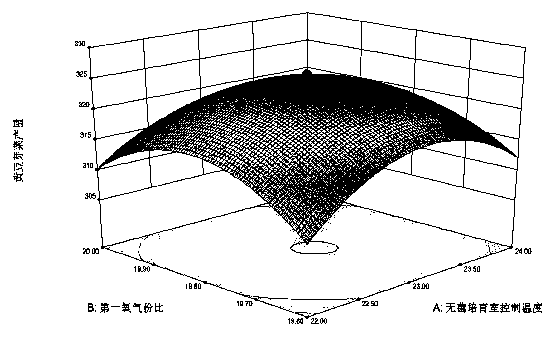

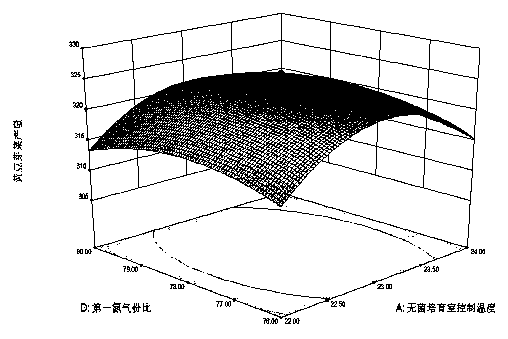

[0060] (6) On the 0th to 3rd day of cultivation, the volume...

Embodiment 2

[0063] Embodiment 2: Production of bean sprouts by controlled atmosphere at an outdoor temperature of 25°C to 35°C

[0064] First, strictly screen 50kg of mung beans as a raw material, put the screened beans into hot water at 80°C for 1 to 2 minutes, and stir at a stirring speed of 30 to 50 rpm. Soak in warm water at 35°C for 90 minutes, the ratio of beans to water is 1:4. After soaking the beans, drain the water and spread the beans evenly in the incubator. The incubator is sterilized by steam at a temperature above 100°C. Move the incubator into the aseptic cultivation room to carry out the controlled atmosphere cultivation system of sprouts. The temperature is controlled at 23°C, and the water temperature of the automatic spraying water every 4 hours is 20°C. On the 0th to 3rd days of cultivation, the volume fraction of circulating gas during cultivation is composed of 19.8% oxygen, 0.031% carbon dioxide, 78% nitrogen, and the rest are rare gases, and the gas circulation v...

Embodiment 3

[0065] Embodiment 3: Production of bean sprouts by controlled atmosphere method at an outdoor temperature of 25°C to 35°C

[0066] For 50kg of mung beans that have been strictly screened, put the screened beans into hot water at 90°C for 1 to 2 minutes, and stir at a stirring speed of 30 to 50 rpm, then soak in warm water at 33°C for 90 After soaking the beans, drain the water and spread the beans evenly in the incubator. The incubator is sterilized by spraying 100PPM sodium hypochlorite. Move the incubator into the aseptic cultivation room to carry out the controlled atmosphere cultivation system for sprouts. The temperature is controlled at 22°C, and the temperature of the automatic spraying water every 4 hours is 20°C. On the 0th to 3rd days of cultivation, the volume fraction of circulating gas during cultivation consists of 19.6% oxygen, 0.030% carbon dioxide, 76% nitrogen, and the rest are rare gases, and the gas circulation is 200 cubic meters per hour. On the 4th to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com