Manufacturing method for field-effect tube and field-effect tube

A manufacturing method and technology of field effect transistors, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as high cost and complicated process, achieve surface damage removal, increase mobility, and achieve ultra-steep sub- Effect of Threshold Swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

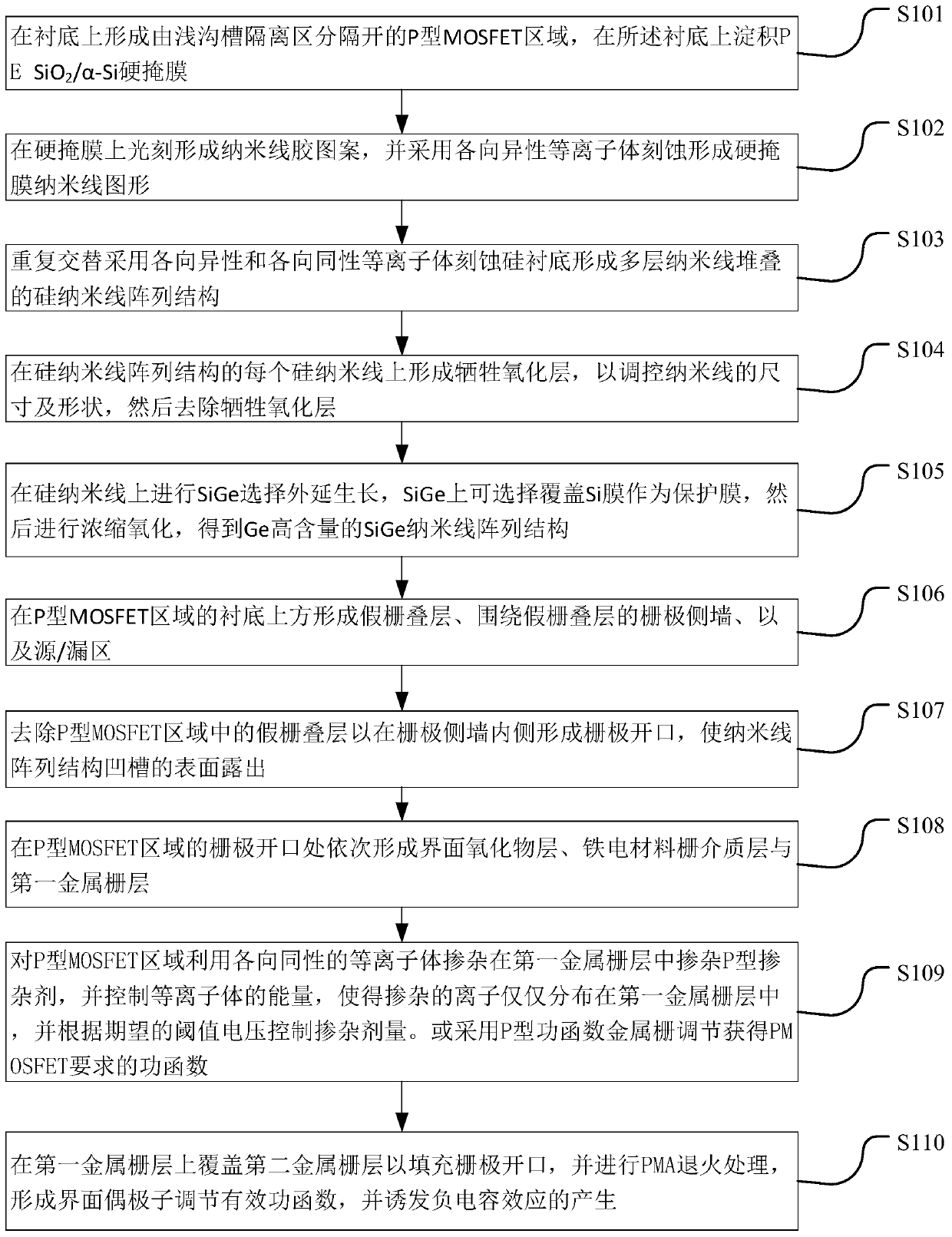

Method used

Image

Examples

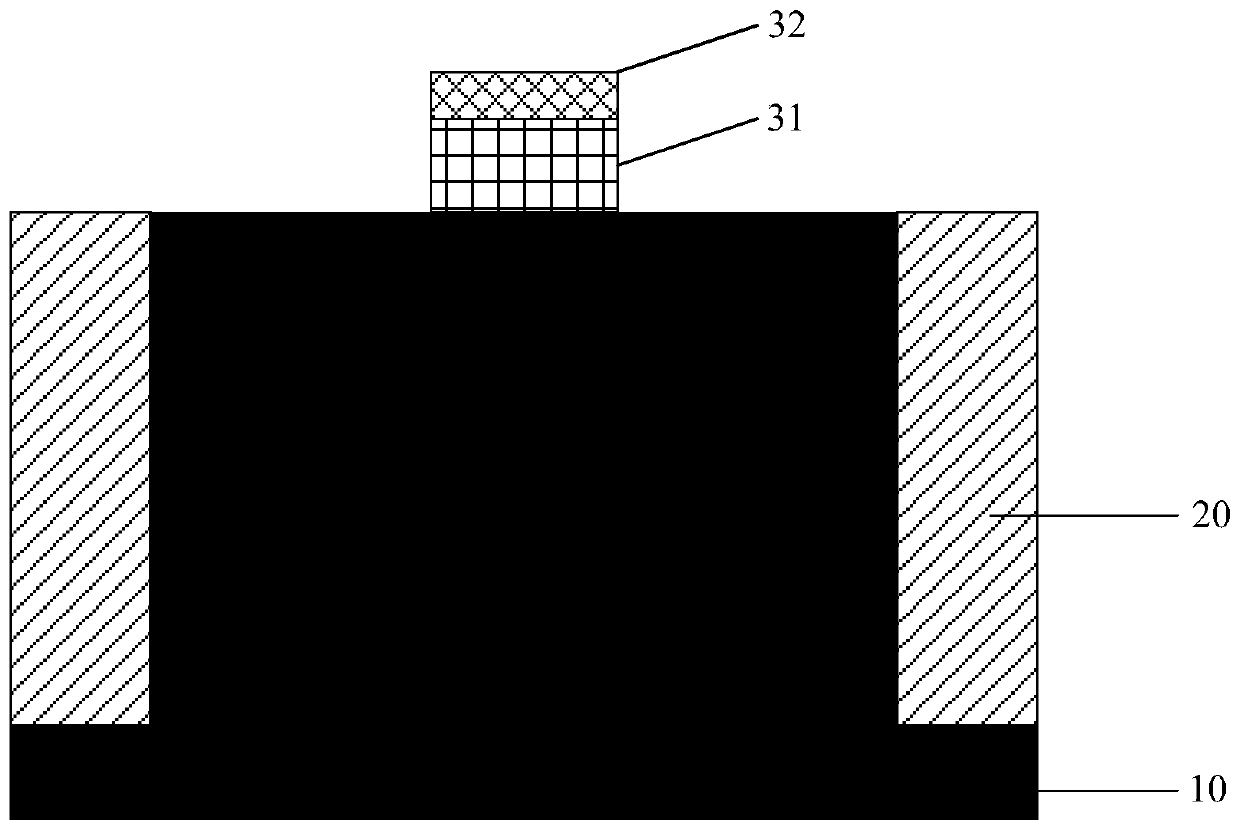

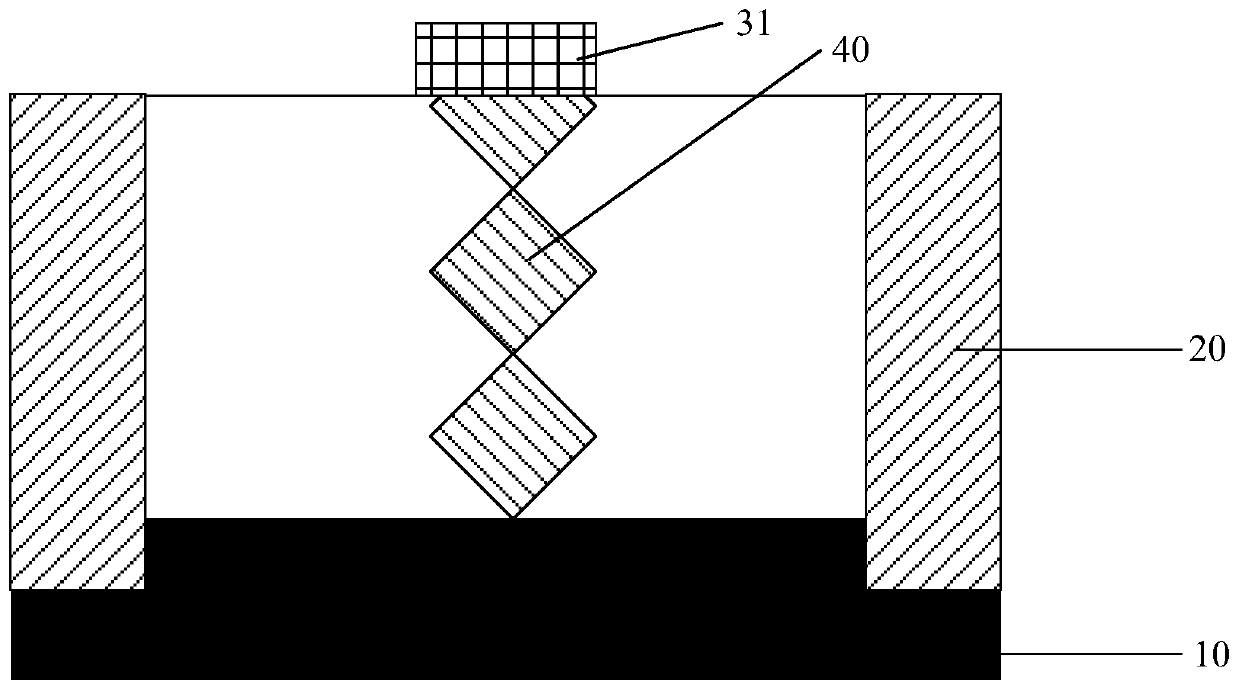

Embodiment Construction

[0073] The present disclosure is to provide a manufacturing method of a field effect tube and a field effect tube. The SiGe nanowire ring gate PMOSFET improves the hole mobility, and at the same time, the compressive stress on the channel generated by the SiGe source / drain further improves the hole mobility. . Moreover, the gate-around structure of the nanowires greatly improves the gate control ability, and suppresses the short channel effect extremely well. In particular, the nanowire array gate-enclosed PMOSFET structure of the present disclosure integrates the negative capacitance effect, effectively increases the surface potential of the device channel, and makes it greater than the external gate voltage, that is, realizes the voltage amplification effect and breaks through the sub-threshold swing glass The Boltzmann limit realizes ultra-steep sub-threshold swing and higher on / off current ratio, meeting the requirements of high-performance PMOSFETs. Therefore, integratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com